Curable composition and cured material

A curable composition and compound technology, applied in the direction of instruments, optics, optical components, etc., can solve the problems of complex manufacturing process, insufficient antioxidant, insufficient yellowing inhibition, etc., and achieve excellent yellowing resistance and not easy yellowing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

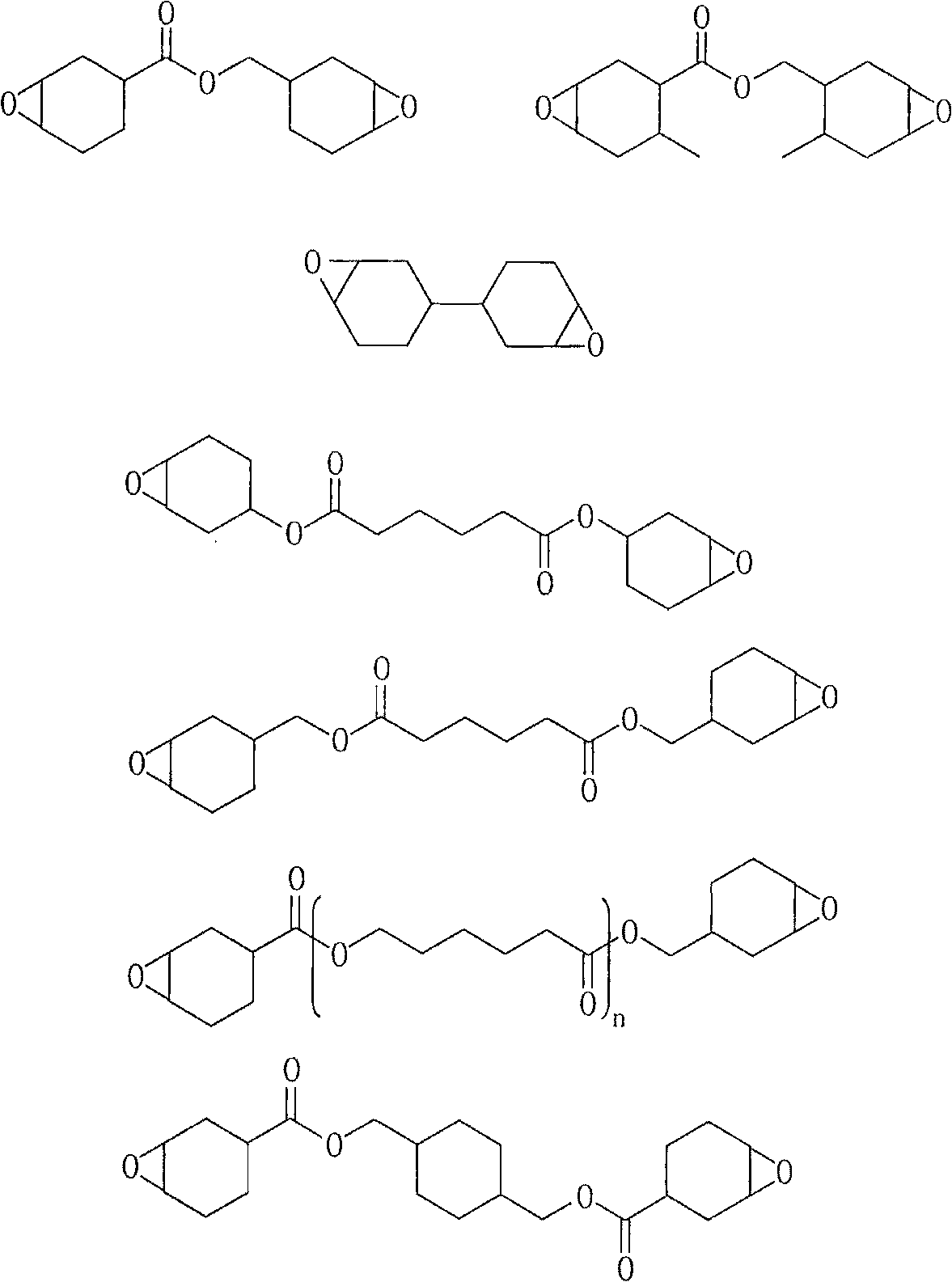

[0163] According to the epoxy compound [2,2-bis(hydroxymethyl)-1-butanol of 1,2-epoxy-4-(2-epoxyethyl)cyclohexane adduct, contained in the above formula ( Among the compounds shown in A2-2), Daicel Chemical Industry Co., Ltd. manufactures, trade name "EHPE 3150"] 30 parts by weight, (meth)acrylate [tricyclo[5.2.1.0 2,6 ] decane dimethanol diacrylate, contained in the compound represented by the above formula (B2-1), manufactured by Daicel-Cytec Company, trade name "IRR 214K"] 50 parts by weight, (methyl) with epoxy group Acrylates [epoxidized dicyclopentenyl acrylate (=3,4-epoxytricyclo[5.2.1.0 2,6 ]decane-8-yl acrylate and 3,4-epoxytricyclo[5.2.1.0 2,6 ] Decane-9-yl acrylate, contained in the compound shown in the above formula (C1-1), manufactured by Daicel Chemical Industry Co., Ltd., trade name "E-DCPA"] 20 parts by weight, acid generator (arylsulfonium Salt acid generator San-Apro, trade name "CPI-100P") 1 part by weight, free radical initiator (acetophenone radical ini...

Embodiment 2

[0166] 1,10-Decanedithiol (HS-C 10 h 21 -SH) instead of decylthiol, it carried out similarly to Example 1, and obtained the cured resin.

Embodiment 3

[0168] Using didecyl sulfide (n-decyl sulfide; C 10 h 21 -S-C 10 h 21 ) instead of decylmercaptan, except that, it was the same as in Example 1 to obtain a cured resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com