Catalytic reaction rectification production method and device for high-purity natural benzaldehyde

A catalytic reaction, benzaldehyde technology, applied in the chemical industry, organic chemistry, hydrolysis to prepare carbonyl compounds and other directions, can solve the problems of the influence of reaction conversion rate and reaction rate, cannot be further improved, and the concentration of reactants is reduced, etc. The yield of natural benzaldehyde, the effect of saving equipment investment and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

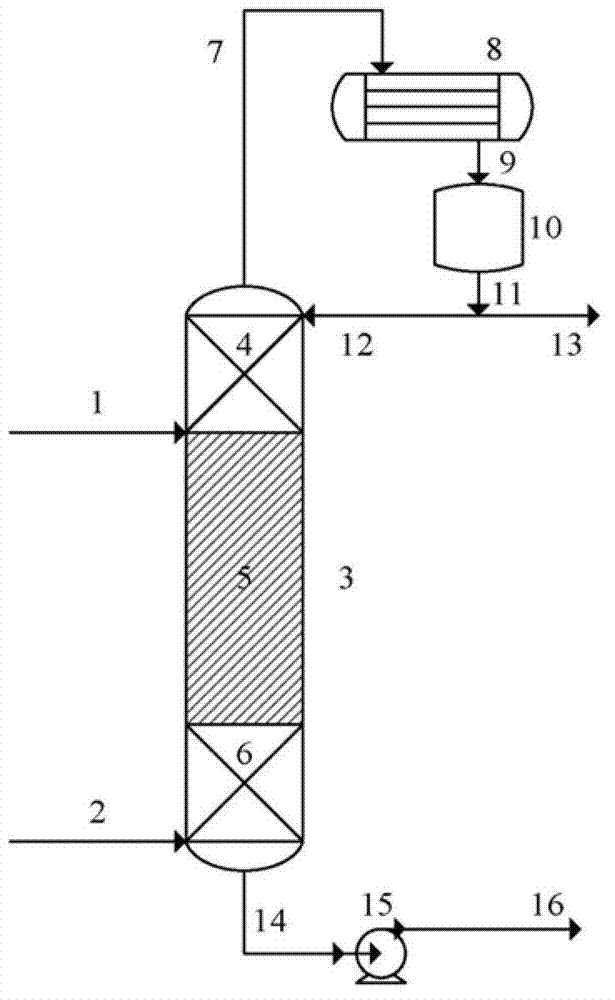

[0032] The method of the present invention is used in the hydrolysis of cinnamon oil to produce natural benzaldehyde process under alkaline conditions, and the processing capacity of cinnamon oil is 10kg / h, which is the same as the flow process described in the present invention, including catalytic reaction rectification tower, tower top condenser, tower The top reflux storage tank and the extraction pump at the bottom of the tower. Since the process requires purification at the top of the tower and purification at the bottom of the tower, the catalytic reaction distillation tower is as follows: figure 1 As shown, it consists of rectification section (4), catalytic reaction section (5) and stripping section (6). The absolute pressure of the catalytic reaction rectification tower is 100Pa, the reflux ratio of the catalytic reaction rectification tower is 2, the mass ratio of feed water vapor to cinnamon oil is 2, and the catalyst consumption is 32kg / m 3 , the content of cinnam...

Embodiment 2

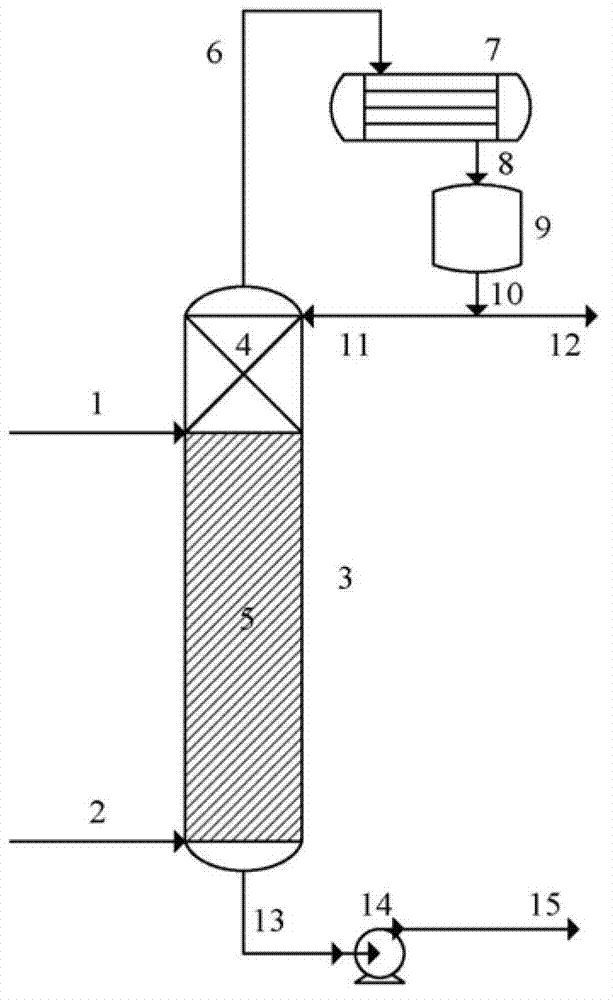

[0037] The method of the present invention is used in the hydrolysis of cinnamon oil to produce natural benzaldehyde process under alkaline conditions, and the processing capacity of cinnamon oil is 1000kg / h, which is the same as the flow process described in the present invention, including catalytic reaction rectification tower, tower top condenser, tower The top reflux storage tank and the extraction pump at the bottom of the tower. Since the process only requires purification at the top of the tower, the catalytic reaction distillation tower is as follows: figure 2 As shown, it consists of a rectification section (4) and a catalytic reaction section (5). The absolute pressure of the catalytic reaction distillation column is 100kPa, the reflux ratio of the catalytic reaction distillation column is 18, the mass ratio of feed water vapor to cinnamon oil is 30, and the catalyst usage is 300kg / m 3 , the content of cinnamaldehyde in cinnamon oil is 85%.

[0038] After the abov...

Embodiment 3

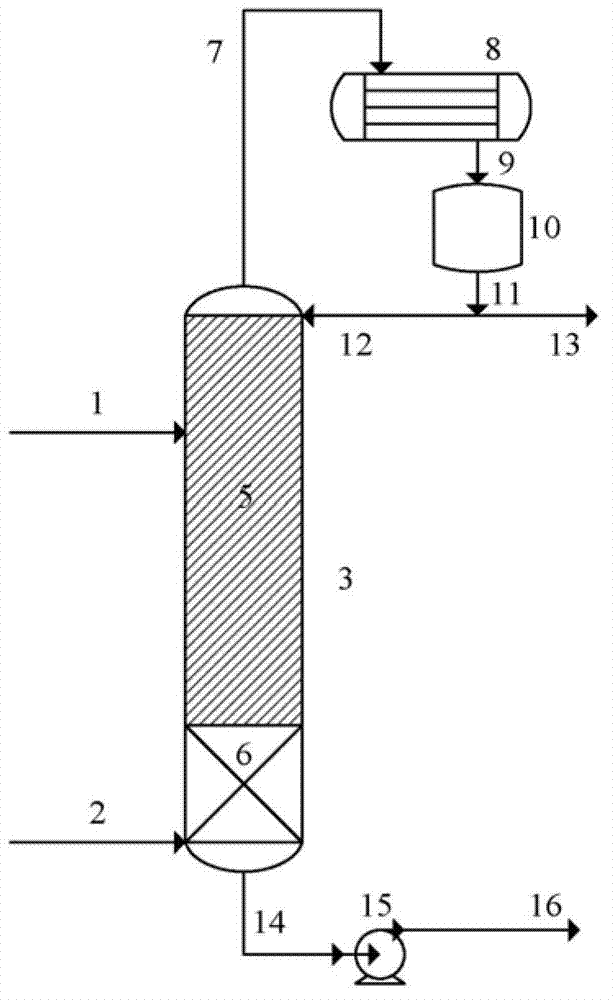

[0042] The method of the present invention is used in the process of producing natural benzaldehyde by hydrolysis of cinnamon oil under alkaline conditions, and the processing capacity of cinnamon oil is 100kg / h, which is the same as the flow process described in the present invention, including catalytic reaction rectification tower, tower top condenser, tower The top reflux storage tank and the extraction pump at the bottom of the tower. Since the process only requires purification at the bottom of the tower, the catalytic reaction distillation tower is as follows: image 3 As shown, it consists of catalytic reaction section (5) and stripping section (6). The absolute pressure of the catalytic reaction distillation column is 10kPa, the reflux ratio of the catalytic reaction distillation column is 10, the mass ratio of feed water vapor to cinnamon oil is 15, and the catalyst usage is 110kg / m 3 , the content of cinnamaldehyde in cinnamon oil is 75%.

[0043] After the above p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com