Preparation method of tetramethyldivinyldisilazane

A technology of tetramethyldivinyldisilazane and dimethylvinylchlorosilane, which is applied in the field of synthetic silicone resin raw material preparation, can solve the problems of a large number of solvents, complicated processes, and reduced yields of similar substances, and achieve simplification The effect of production process, avoiding complicated process and avoiding side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The invention provides a preparation method of tetramethyldivinyldisilazane, which comprises the following steps: step a) adding dimethylvinylchlorosilane into a reaction kettle, and feeding ammonia gas under stirring conditions for reaction, the resulting The mass ratio of dimethylvinylchlorosilane to ammonia is 4.30~4.40:1, the reaction temperature is 110~115°C, and the reaction pressure is 0.15~0.18MPa; step b) add sodium hydroxide solution into the reaction kettle, and after stirring Tetramethyldivinyldisilazane is obtained.

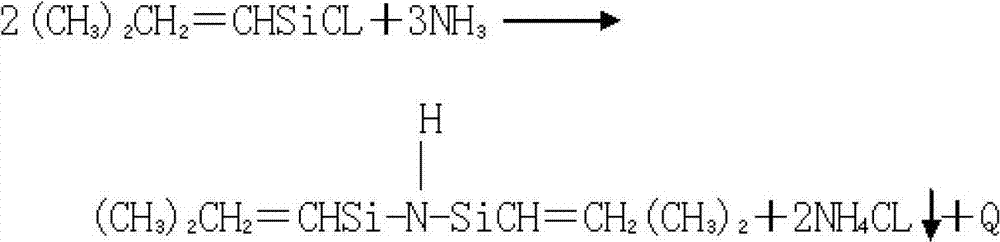

[0021] In the above preparation process, the present invention reacts dimethylvinylchlorosilane and ammonia under solvent-free conditions, which simplifies the production process, reduces energy consumption, and increases the yield. The ammonia gas is preferably stored in the form of liquid ammonia, and the liquid ammonia is converted into ammonia gas during the process of passing the liquid ammonia into the reactor. The reaction formula of d...

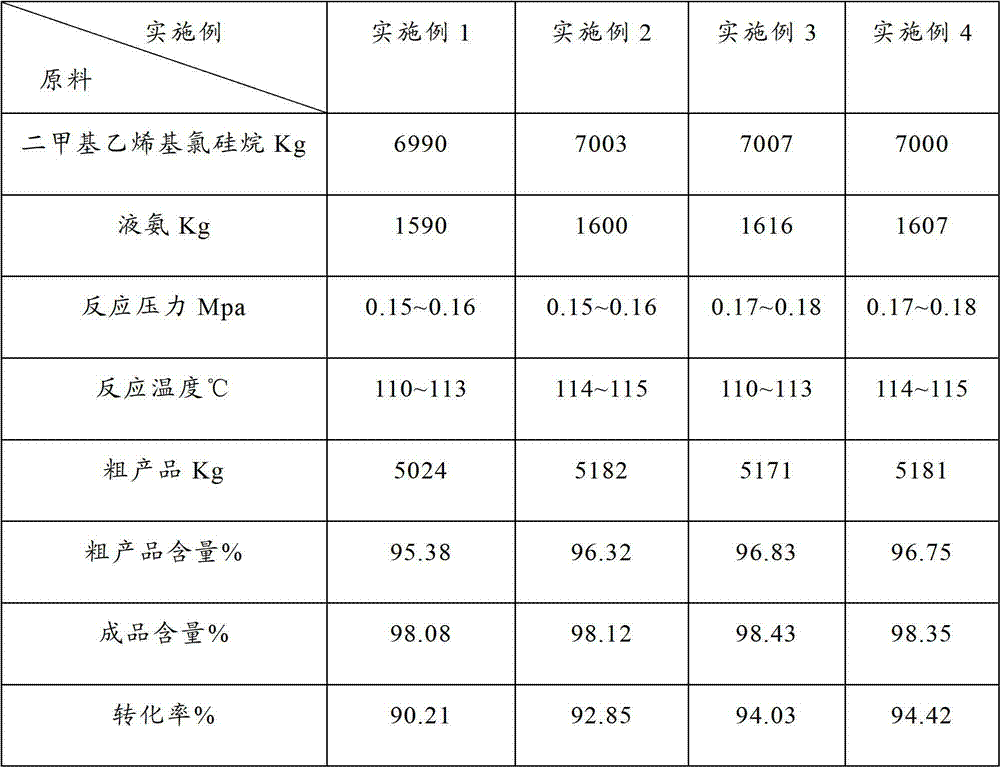

Embodiment 1~4

[0034] Pump dimethyl vinyl chlorosilane into 1m 3 In the enamel reaction kettle, stir at a speed of 120 rpm, and at the same time slowly add liquid ammonia raw materials for reaction. The reaction time is 12 hours, and the ammonia flow rate reaches 99% within 2 hours. Control the reaction temperature and reaction pressure. The temperature of the water close to the jacket does not change within one hour, and the pressure remains unchanged for 180 minutes after the pressure approaches the upper limit of the operation;

[0035] Add 200Kg of concentrated 25% sodium hydroxide solution to the reaction kettle, stir for 30min, and obtain the crude product of tetramethyldivinyldisilazane;

[0036] The crude product of tetramethyldivinyldisilazane is subjected to batch rectification to obtain the finished product of tetramethyldivinyldisilazane.

[0037] Raw material ratio and reaction conditions of table 1 embodiment 1~4

[0038]

[0039] It can be seen from the above examples tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com