Organosilicone modified phenolic aldehyde injection molding material and preparation method thereof

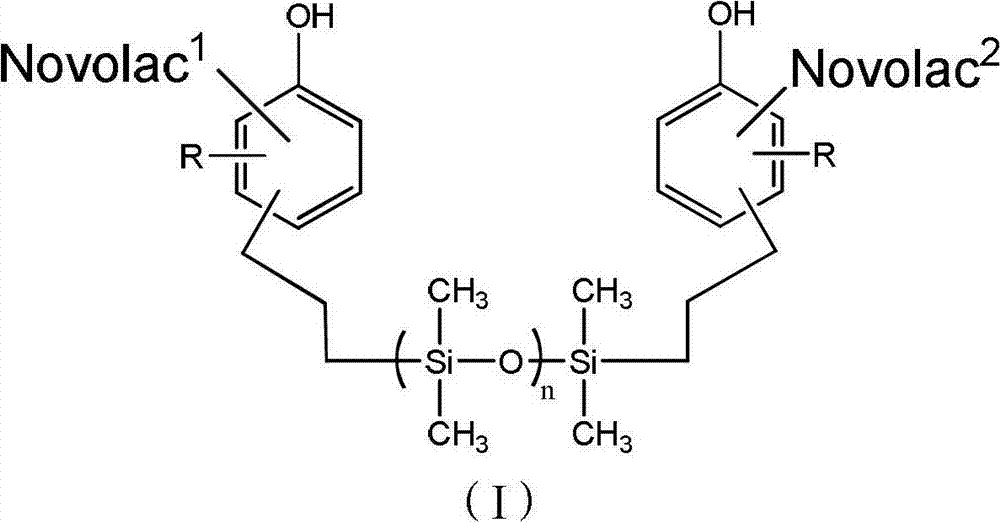

A silicone and injection molding technology, which is applied in the field of organic silicon modified phenolic injection molding and its preparation, can solve the problems of inability to improve the heat resistance and storage stability of injection molding, high production costs, and limitations in application fields, and achieve Improved water absorption and weather resistance, long storage time, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

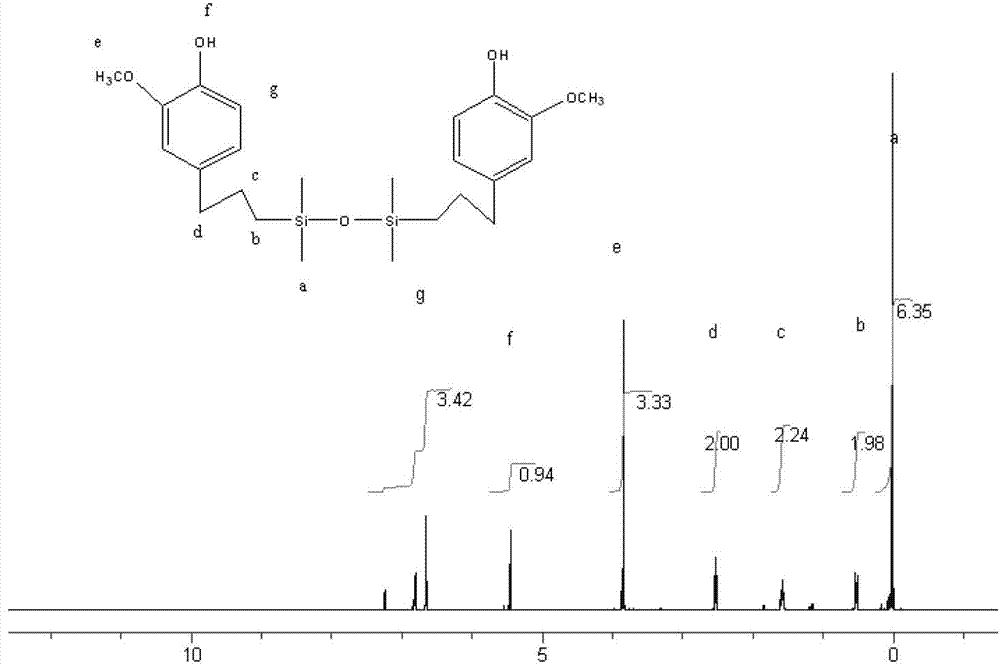

[0043] (1) Preparation of organosilicon modifier: Add eugenol (164kg, 1000mol) and 15g of chloroplatinic acid into the synthesis reaction kettle, stir and heat up to about 60°C, and add 1,1,3,3-tetramethyldisilazol Oxygen (67kg, 500mol) was added dropwise into the reactor in batches to keep the temperature not higher than 80°C, and the reaction was carried out until the end of the heating phenomenon and then continued for 2-3 hours to obtain the organosilicon modifier with a yield of 93% , the structural formula and nuclear magnetic spectrum of the organosilicon modifier are as follows figure 1 shown.

[0044] (2) Preparation of organosilicon-modified thermoplastic phenolic resin: Add 80 kg of phenol and 10 kg of organosilicon modifier prepared by the above method into the synthesis reaction kettle, heat up and stir, add an appropriate amount of oxalic acid to adjust the pH<2, and the temperature rises to about 85°C Add dropwise 45 kg of formaldehyde solution with a mass perc...

preparation example 2

[0047] (1) Preparation of organosilicon modifier: Add eugenol (82kg, 500mol) and 9g of chloroplatinic acid into the synthesis reaction kettle, stir and heat up to about 60°C, and add 1,1,3,3-tetramethyldisilica Oxane (33.5kg, 250mol) was added dropwise into the reactor in batches to keep the temperature not higher than 80°C, and the reaction was carried out until the end of the temperature rise phenomenon and continued for 2-3 hours to obtain an organosilicon modifier with a yield of 94 %.

[0048] (2) Preparation of organosilicon-modified thermoplastic phenolic resin: add 100kg of phenol and 10kg of organosilicon modifier prepared by the above method to the synthesis reaction kettle, add oxalic acid to adjust the pH of the system to about 2, heat up and stir, and the temperature rises to about 85°C, drop 55kg of 37% formaldehyde solution by mass and keep it warm for 2 hours until the system becomes turbid, then vacuumize and dehydrate under reduced pressure under heating, sto...

preparation example 3

[0051] (1) Preparation of organosilicon modifier: Add 2-allylphenol (133kg, 1000mol) and 15g of chloroplatinic acid into the synthesis reaction kettle, stir and heat up to about 60°C, and mix 1,1,3,3-tetra Methyldisiloxane (67kg, 500mol) was added dropwise into the reactor in batches to keep the temperature not higher than 80°C, and the reaction continued for 2-3 hours after the end of the temperature rise phenomenon, and the organosilicon modifier was obtained. Yield 91%.

[0052] (2) Preparation of organosilicon-modified thermoplastic phenolic resin: Add 80kg of phenol and 10kg of organosilicon modifier prepared by the above method into the synthesis reaction kettle, add oxalic acid to adjust the pH of the system to about 2, heat up and stir, and the temperature rises to about Add 45 kg of formaldehyde solution with a mass percentage of 37% dropwise at 85°C, keep it warm for 2 hours until the system becomes turbid, then vacuumize and dehydrate the system under heating until ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com