High-base-number compound-sulfonic lithium/calcium composite lubricating grease and preparation method thereof

A technology of compound lithium sulfonate and lubricating grease, which is applied in the direction of lubricating composition, petroleum industry, thickener, etc., to achieve the effect of good high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

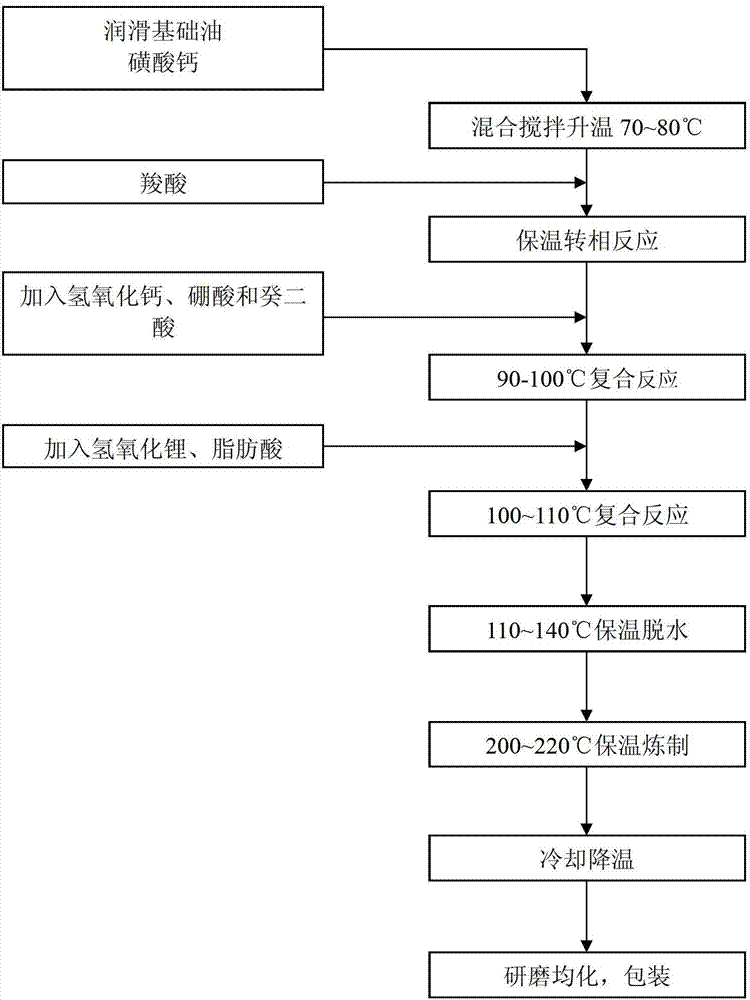

[0021] according to figure 1 The flow chart shown in the preparation of high alkali value complex lithium calcium sulfonate complex grease:

[0022] (1) Take 20g of synthetic calcium sulfonate and 38g of paraffin-based mineral oil into an open reaction kettle, stir and mix, heat up to 70°C, add 1.7g of glacial acetic acid, stir and mix evenly, and keep it warm for 60 minutes.

[0023] (2) After the material is thickened, heat up to 90°C, add 1.5g of calcium hydroxide, 1.7g of boric acid, and 5.5g of sebacic acid, stir and mix evenly, and keep warm for 30 minutes.

[0024] (3) Raise the temperature to 100°C, add 0.5g of lithium hydroxide and 7g of 12-hydroxystearic acid, stir and mix evenly, and keep it warm for 50 minutes, then raise the temperature to 200°C for refining, and hold it for 50 minutes.

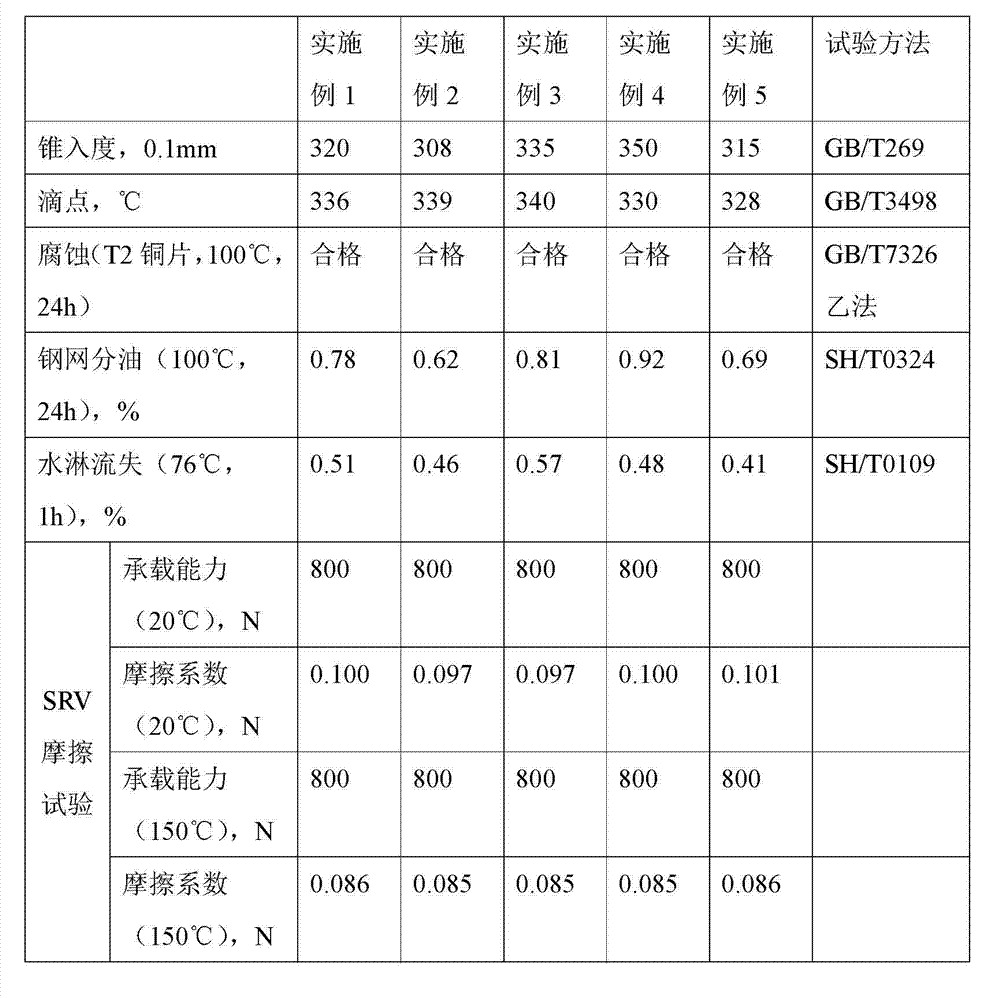

[0025] (4) Cool down. When the temperature drops below 50°C, it will be ground and homogenized to be a finished product. Its properties are shown in Table 1.

Embodiment 2

[0027] according to figure 1 The flow chart shown in the preparation of high alkali value complex lithium calcium sulfonate complex grease:

[0028] (1) Take 20g of synthetic calcium sulfonate and 30g of paraffin-based mineral oil into the open reaction kettle, stir and mix, raise the temperature to 75°C, add 1.7g of glacial acetic acid, stir and mix evenly, and keep it warm for 70 minutes.

[0029] (2) After the material is thickened, heat up to 95°C, add 1g of calcium hydroxide, 1.7g of boric acid, and 2.8g of sebacic acid, stir and mix evenly, and keep warm for 40 minutes.

[0030] (3) Raise the temperature to 105°C, add 0.8g of lithium hydroxide and 10g of 12-hydroxystearic acid, stir and mix evenly, and keep it warm for 55 minutes, then raise the temperature to 210°C for refining, and hold it for 60 minutes.

[0031] (4) Cool down. When the temperature drops below 50°C, it will be ground and homogenized to be a finished product. Its properties are shown in Table 1.

Embodiment 3

[0033] according to figure 1 The flow chart shown in the preparation of high alkali value complex lithium calcium sulfonate complex grease:

[0034] (1) Take 20g of petroleum calcium sulfonate and 15g of paraffin-based mineral oil into an open reaction kettle, stir and mix, heat up to 80°C, add 1.6g of glacial acetic acid, stir and mix evenly, and keep it warm for 70 minutes.

[0035] (2) After the material is thickened, heat up to 100°C, add 1g of calcium hydroxide, 1.7g of boric acid, and 2.8g of sebacic acid, stir and mix evenly, and keep warm for 50 minutes.

[0036] (3) Raise the temperature to 110°C, add 0.25g of lithium hydroxide and 2.7g of stearic acid, stir and mix evenly, and keep it warm for 70 minutes, then raise the temperature to 220°C for refining, and hold it for 80 minutes.

[0037] (4) Cool down. When the temperature drops below 50°C, it will be ground and homogenized to be a finished product. Its properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| drop melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com