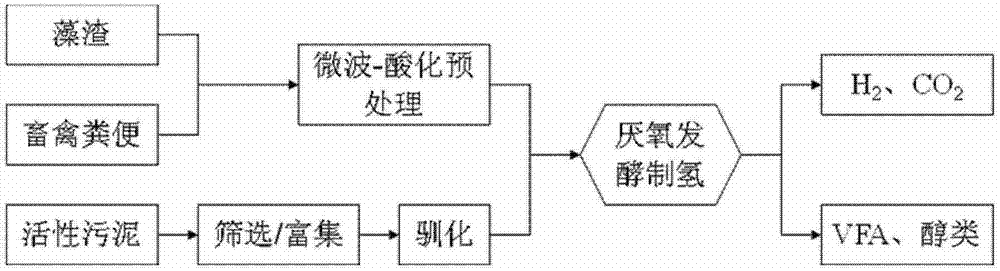

Algal residue and livestock/poultry feces coupled anaerobic fermentation method for producing hydrogen

A technology for livestock and poultry manure and anaerobic fermentation, applied in the direction of fermentation, can solve problems such as environmental pollution, and achieve the effects of improving hydrogen production, easy operation and control, and shortening start-up time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1. Substrate pretreatment

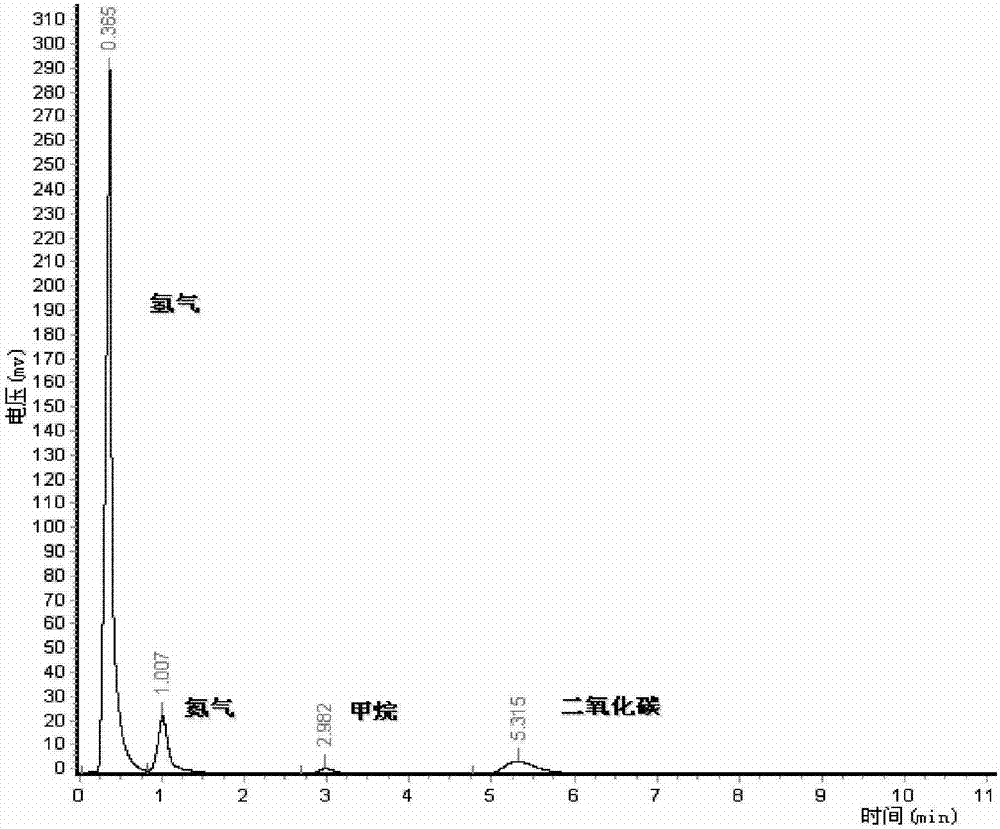

[0041] The dried algae powder was extracted with diethyl ether-petroleum ether as the extraction agent, the volume ratio of diethyl ether and petroleum ether was 1:1, and the temperature was extracted at 30°C for 4 hours. The algae were collected by centrifugation and dried at 105°C for later use. The algae residue and pig manure were respectively placed in a microwave generator at 200w for 30 minutes (the treatment time was controlled in a state where the algae residue and pig manure had not been carbonized), and cooled to room temperature after taking it out. Use 5 mol / L hydrochloric acid to adjust the pH of the substrate to 3, and after acidification for 24 hours, wash until the pH reaches 6.

[0042] 2. Activated sludge screening and domestication

[0043] The activated sludge from the pig manure anaerobic digester was passed through a 50-mesh sieve to remove large particles, and most of the methanogens were removed through acidification...

Embodiment 2

[0048] Using prokaryotic chlorella with autotrophic and heterotrophic dual growth capabilities, first obtain high-concentration algae liquid under heterotrophic culture conditions. After the concentration of algae liquid reaches 40g / L, it is centrifuged and freeze-dried to obtain chlorella algae powder. The dried algae powder was broken down by ultrasonic waves, and diethyl ether-petroleum ether (volume ratio: 2:1) was used as the extractant, extracted at 35°C for 4 hours, and the algae were collected by centrifugation and dried at 105°C for later use. The chlorella residue and pig manure (mass ratio 2:1) were placed in a microwave generator at 600w and treated for 10 minutes (the algae residue and pig manure could not be carbonized), and then the pH value of the substrate was adjusted to 3. After acidification treatment for 24 hours, wash to pH 6. Insert the acclimated activated sludge into the pretreated chlorella residue and pig manure mixed substrate, the inoculation amoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com