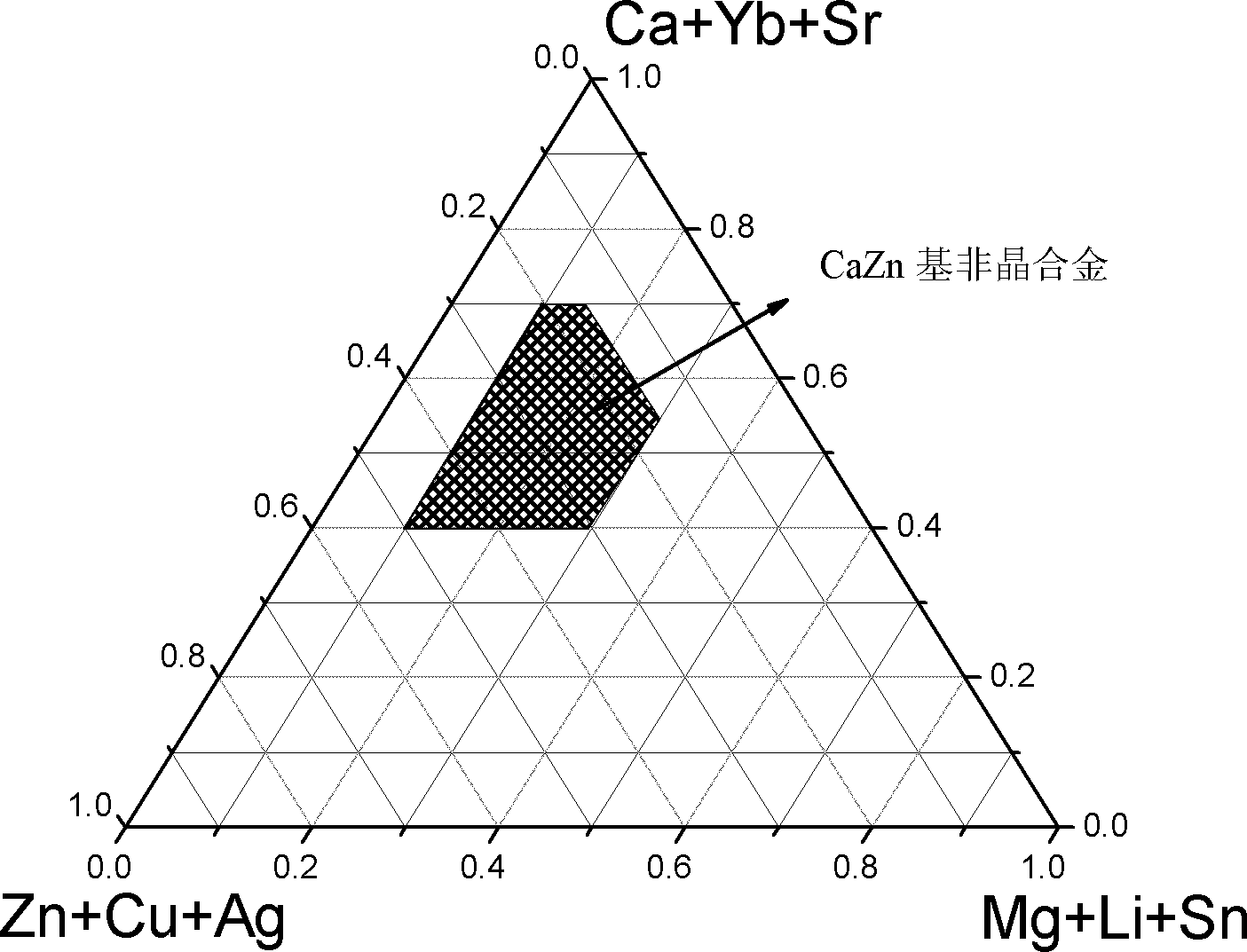

Biomedical controllable degradable CaZn base amorphous alloy

An amorphous alloy, biomedical technology, applied in the biomedical field, can solve the problems of limiting the direct use of Ca and its conventional alloys, and achieve the effects of ensuring mechanical stability, high elastic strain, and low magnetic susceptibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

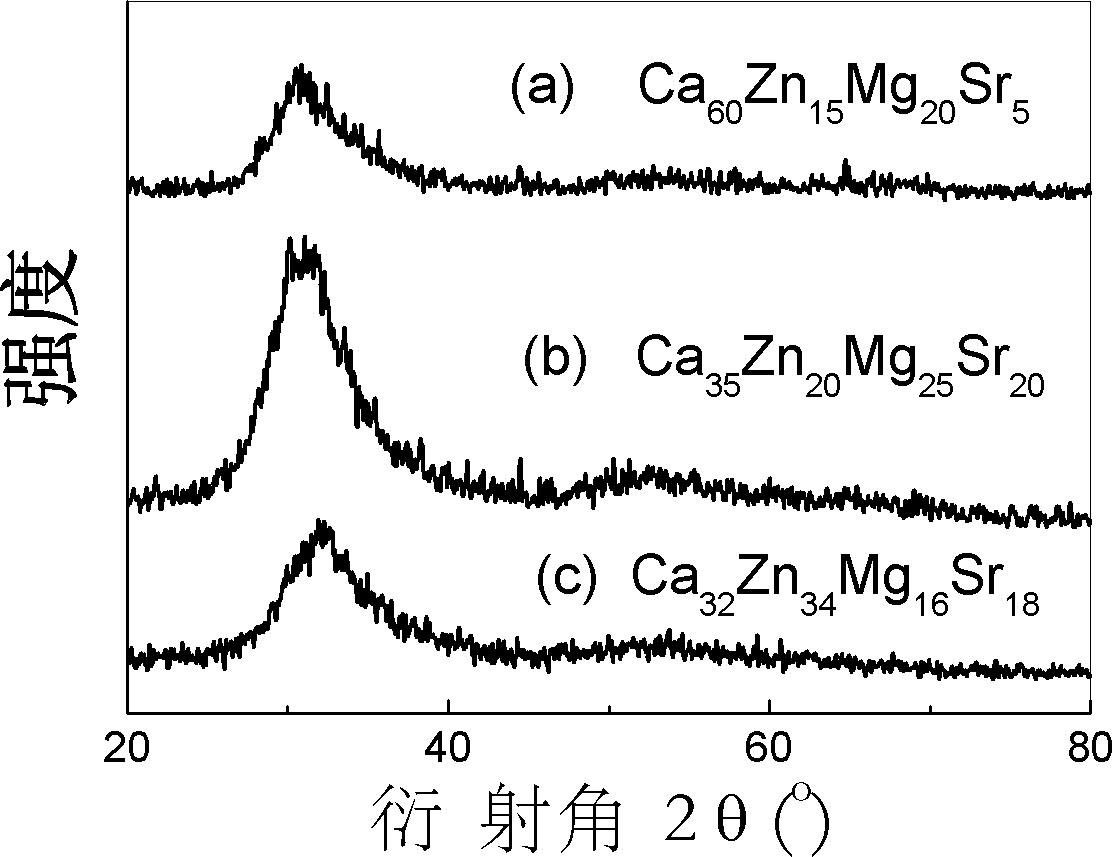

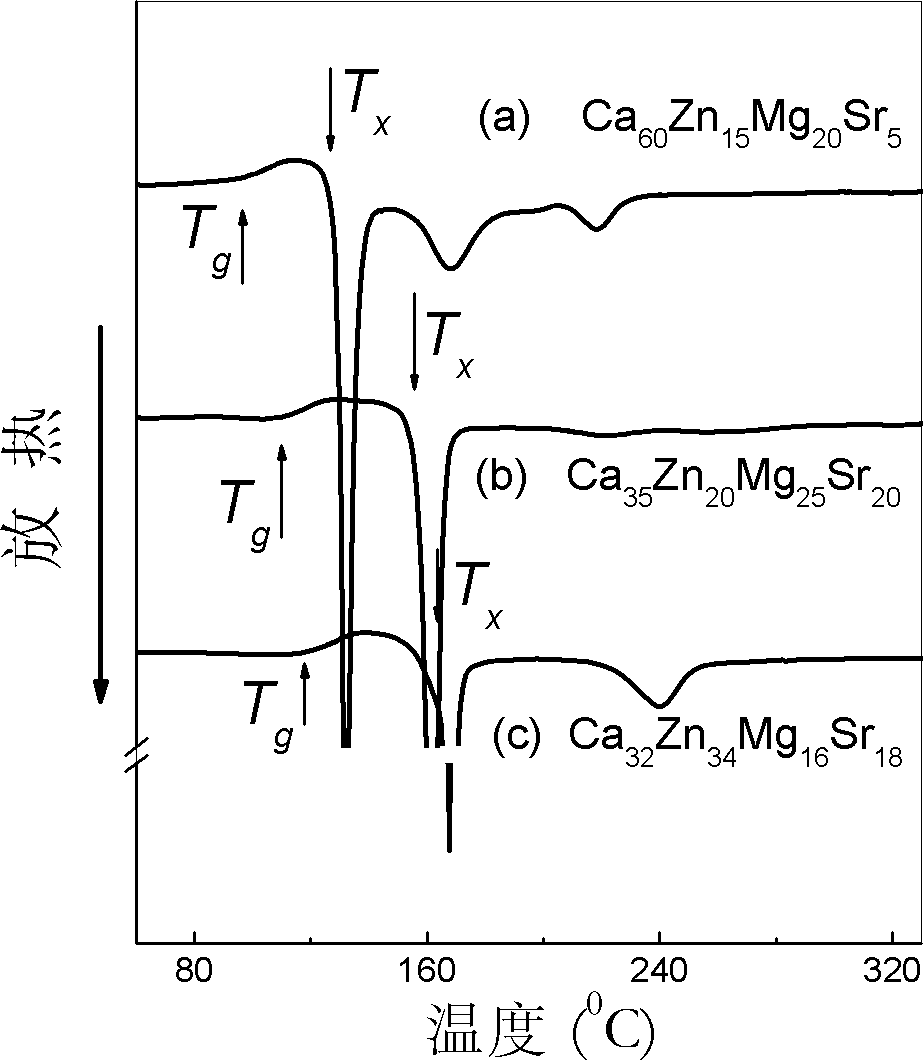

[0036] Embodiment 1: CaZn-based amorphous alloy Ca 60 Zn 15 Mg 20 Sr 5 preparation of

[0037] After the Ca and Sr raw materials with a purity of not less than 99wt% and the four components of Zn and Mg with a purity of not less than 99.9wt% are prepared in a molar ratio of 60:15:20:5, the raw materials are placed in a quartz tube and placed in a high frequency induction furnace. Use a vacuum pump to evacuate to 5.0×10 -4 Above Pa, after filling with an appropriate amount of high-purity argon, heat it with a high-frequency coil and small current until it melts. Stir evenly with electromagnetic, and spray-cast it into a copper mold cooled with liquid nitrogen, that is, the composition is Ca 60 Zn 15 Mg 20 Sr 5 , A bulk amorphous alloy with a diameter of 5 mm; if sprayed on a rotating copper wheel, amorphous strips can be obtained, and powder can be obtained after ball milling. The material has good biocompatibility and mechanical properties, and can b...

Embodiment 2

[0041] Embodiment 2: CaZn-based amorphous alloy Ca 35 Zn 20 Mg 25 Sr 20 preparation of

[0042] After the Ca and Sr raw materials with a purity of not less than 99wt% and the four components of Zn and Mg with a purity of not less than 99.9wt% are prepared in a molar ratio of 35:20:25:20, the raw materials are placed in a quartz tube and placed in a high frequency induction furnace. Use a vacuum pump to evacuate to 5.0×10 -4 Above Pa, after filling with an appropriate amount of high-purity argon, heat it with a high-frequency coil and small current until it melts. Stir evenly with electromagnetic, and spray-cast it into a copper mold cooled with liquid nitrogen, that is, the composition is Ca 35 Zn 20 Mg 25 Sr 20 , A bulk amorphous alloy with a diameter of 2mm; if sprayed on a rotating copper wheel, amorphous strips can be obtained, and powder can be obtained after ball milling. The material has good biocompatibility and mechanical properties, and can...

Embodiment 3

[0046] Embodiment 3: CaZn-based amorphous alloy Ca 32 Zn 34 Mg 16 Sr 18 preparation of

[0047] After the Ca and Sr raw materials with a purity of not less than 99wt% and the four components of Zn and Mg with a purity of not less than 99.9wt% are prepared in a molar ratio of 32:34:16:18, the raw materials are placed in a quartz tube and placed in a high frequency induction furnace. Use a vacuum pump to evacuate to 5.0×10 -4 Above Pa, after filling with an appropriate amount of high-purity argon, heat it with a high-frequency coil and small current until it melts. Stir evenly with electromagnetic, and spray-cast it into a copper mold cooled with liquid nitrogen, that is, the composition is Ca 32 Zn 34 Mg 16 Sr 18 A bulk amorphous alloy; if sprayed on a rotating copper wheel, amorphous strips can be obtained, and powder can be obtained after ball milling. The material has good biocompatibility and mechanical properties, and can be degraded and absorbed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com