Preparation method of zinc-nickel coating for ironwork

A technology for iron products and coatings, which is applied to the preparation of coatings for iron products and the preparation of zinc-nickel coatings for iron products, can solve the problems of easy peeling strength, high temperature resistance, environmental safety hazards, etc., and achieves reasonable process arrangement and preparation. The cost is moderate and the effect that meets the performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

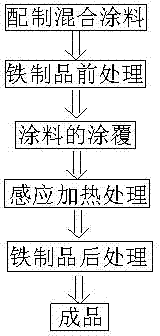

Image

Examples

Embodiment

[0018] The specific preparation process of the preparation method of the zinc-nickel coating on iron products mentioned in the present invention is as follows:

[0019] a) Prepare mixed paint. The main ingredients of the paint are: 60% zinc powder, 35% nickel powder, 3% cobalt powder and 2% chromium powder. Appropriate auxiliary materials need to be added during the preparation process of the paint. The main components are: antirust agent, active agent, antifoaming agent and diluent; among them, the antirust agent is zinc aluminate, the active agent is silicone oil, the antifoaming agent is silicone defoamer, and the diluent is deionized water. The percentage distribution ratio of auxiliary materials is about 1:1.5:3.5:20; the percentage distribution ratio of the above-mentioned main materials and auxiliary materials is about 1:8; when in use, the main materials and auxiliary materials are added to the reactor for sufficient mechanical stirring, spare;

[0020] b) Pre-treatme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com