Process for producing gas-phase natural gas and liquid-phase natural gas through nitrogen-methane separation in nitrogen-containing natural gas

A technology of liquid-phase natural gas and gas-phase natural gas, which is applied in the direction of cold treatment separation, liquefaction, refrigeration and liquefaction, etc. It can solve the problems of high equipment investment, high energy consumption, and low condensation temperature of the overhead condenser of the rectification tower, so as to reduce equipment The effect of investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

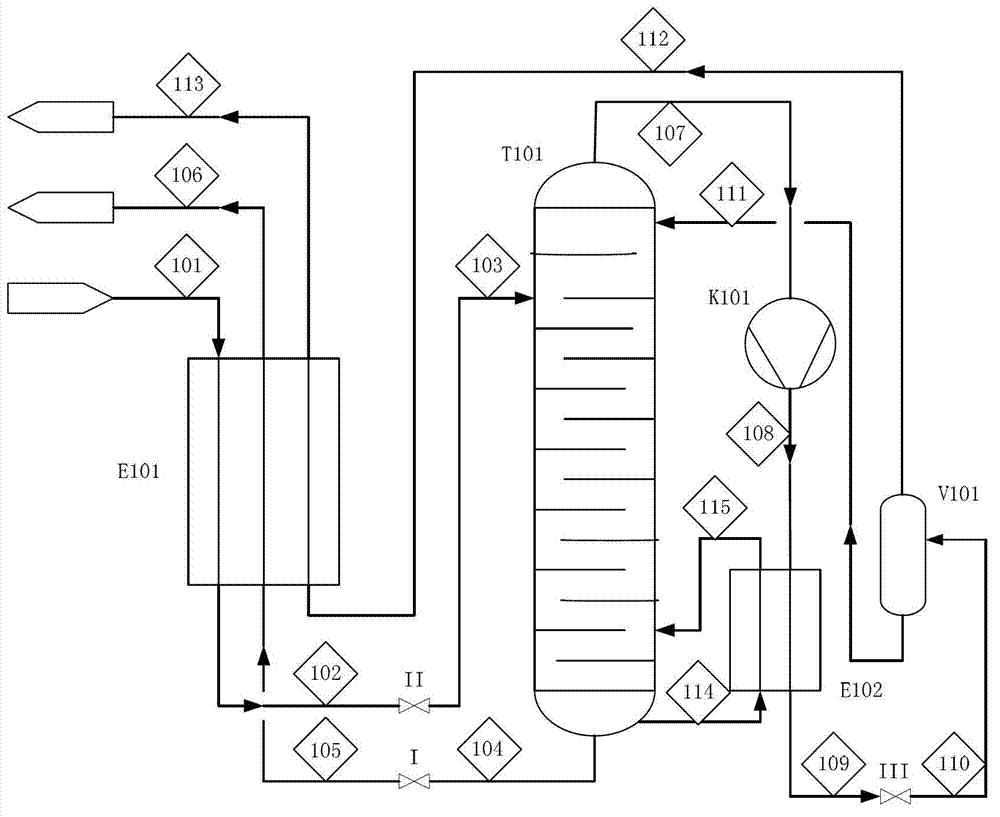

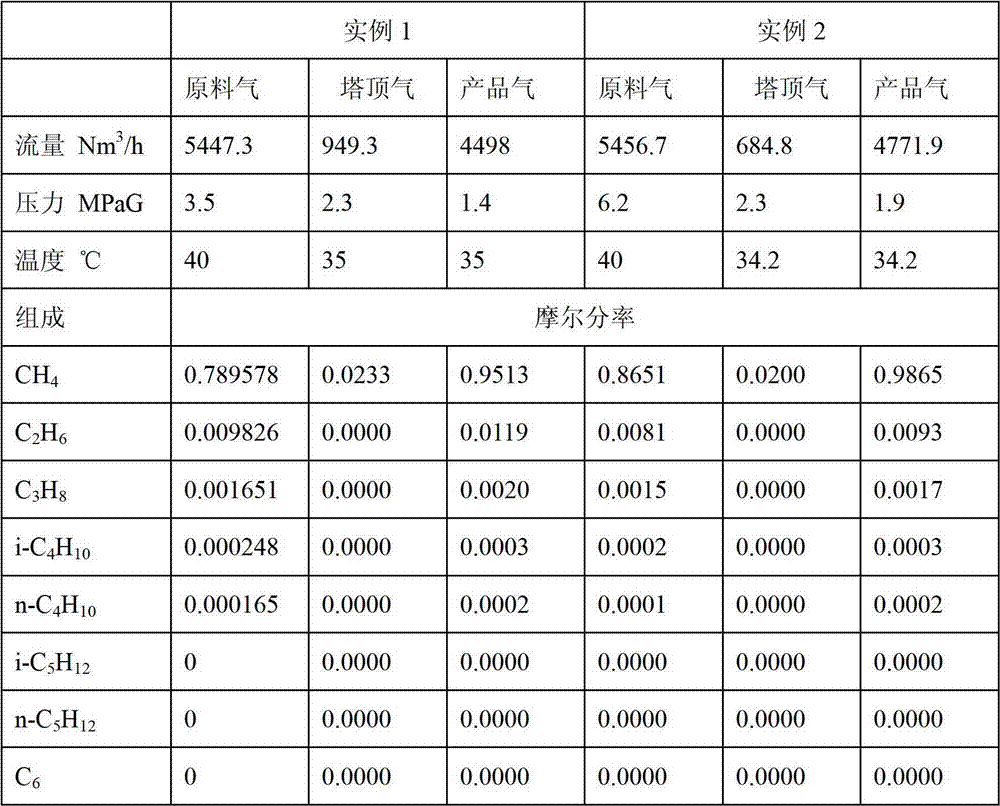

[0029] Such as figure 1 As shown, the nitrogen-methane separation of nitrogen-containing natural gas in offshore natural gas fields listed in this embodiment takes gaseous natural gas as the target product.

[0030] The purified raw gas 101 is first condensed into a liquid state 102 in the main heat exchanger E101, and then enters the rectification tower T101 from the middle inlet of the rectification tower T101 after passing through the throttle valve II to reduce the pressure.

[0031] The nitrogen-rich gas phase 107 flows out of the top of the rectification tower T101, and after being compressed by the first compressor K101, it flows into the top condenser and the bottom reboiler coupling heat exchanger E102 with the stream stream 108, and flows into the top of the tower from the bottom of the tower. The condenser and the bottom reboiler coupling heat exchanger E102 exchange heat in the liquid phase 114, and the nitrogen-enriched stream 109 flowing out of the top condenser ...

example 2

[0036] The flow chart of this embodiment is as follows figure 1 As shown, this embodiment cites the use of coke oven gas to synthesize natural gas containing nitrogen, and the separation of nitrogen and methane is realized through the present invention, and gaseous natural gas is the target product.

[0037] The pressure of the synthetic natural gas is 6.2MPa. The purified raw gas 101 enters the denitrification device, and is first condensed into a liquid 102 in the main heat exchanger E101, and then, after the pressure is reduced by the throttle valve II, it is discharged from the middle part of the rectification tower T101 The inlet enters the rectification column T101.

[0038] The nitrogen-rich gas phase 107 flows out of the top of the rectification tower T101, and after being compressed by the first compressor K101, it flows into the top condenser and the bottom reboiler coupled heat exchanger E102 with the stream stream 108, and flows into the top of the tower with the s...

example 3

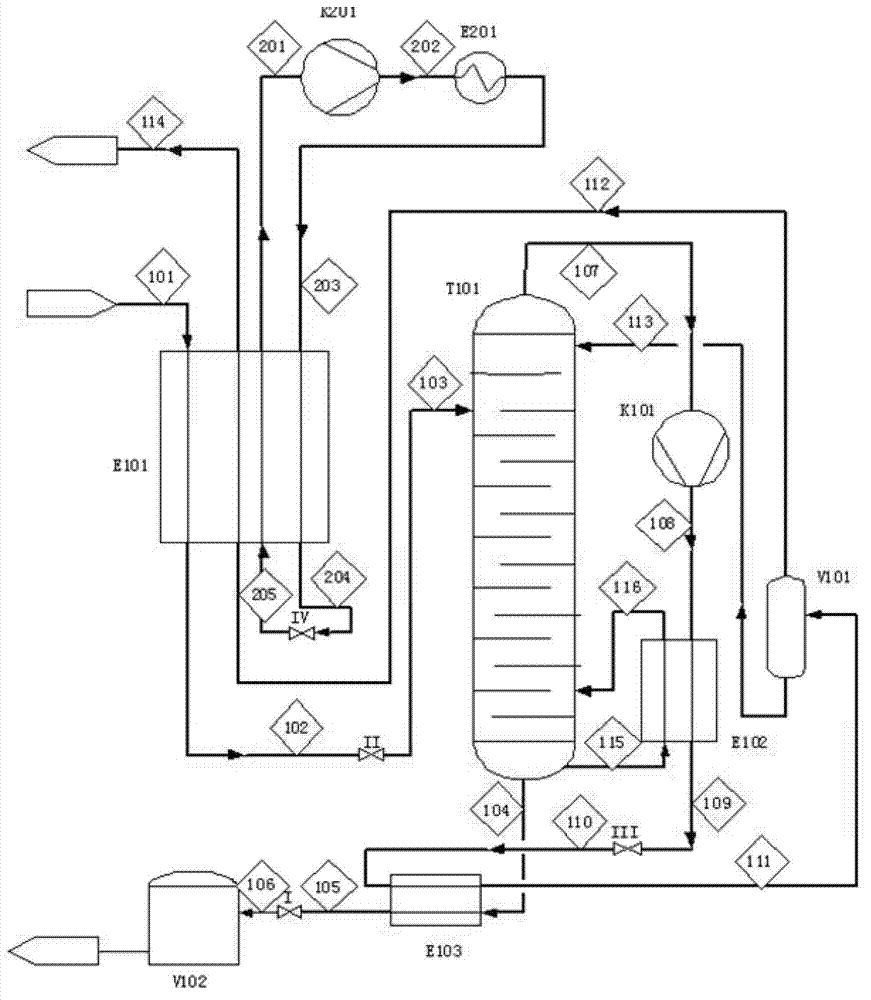

[0046] The schematic flow chart of this embodiment is attached figure 2 As shown, this embodiment cites the use of oil field gas as raw material gas after nitrogen flooding, and liquefied natural gas (LNG) as the target product after utilizing the nitrogen-methane separation process.

[0047] The oilfield gas pressure is 4.8MPa. The purified raw gas 101 enters the denitrification device, and is first condensed into a liquid 102 in the main heat exchanger E101, and then the pressure is reduced by the throttle valve II, and then enters from the middle of the rectification tower T101 Into the rectification column T101.

[0048] Among them, the main heat exchanger E101 also needs to adopt the way of mixed refrigerant circulation to obtain cooling capacity. In this example, CH 4 、C 2 h 4 、C 3 h 8 , i-C 5 h 12 The prepared mixed refrigerant 201 is compressed by the second compressor K201 to obtain a compressed mixed refrigerant 202, and the mixed refrigerant 202 is cooled by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com