Preparation method of composite whitening lipid nanoparticle emulsion

A lipid nanoparticle, whitening technology, applied in skin care preparations, pharmaceutical formulations, cosmetic preparations, etc., can solve problems such as extensive use of active substances, poor stability, crystallization, etc., and is conducive to skin absorption and stability. Good sex, increase the effect of transdermal absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

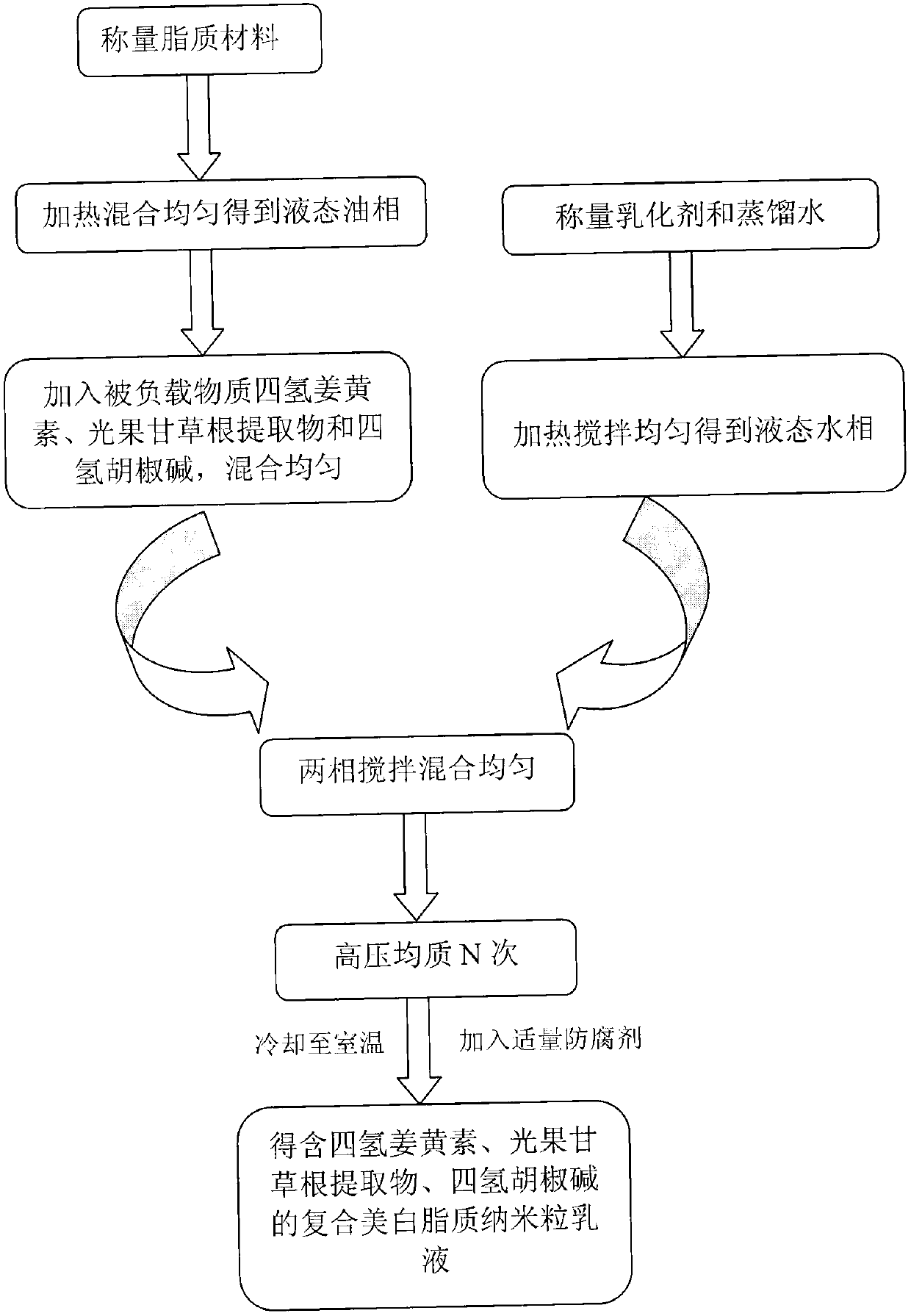

[0022] A preparation method of composite whitening lipid nanoparticle emulsion adopts the following steps:

[0023] A. Weigh 18.0g hydrogenated soybean oil (HYDROGENATED SOYBEAN OIL), 16.0g stearic acid monoglyceride (GLYCERYL STEARATE) in a beaker, heat in a water bath at 75°C to obtain a liquid oil phase;

[0024] B. Weigh 4.2g tetrahydrocurcumin, 2.7g licorice root extract, 0.6g tetrahydropiperine by the ratio of 7: 4.5: 1, add it to the above-mentioned liquid oil phase, and control the stirring speed to be 500rpm, stir for 5 minutes, stir and mix evenly, and keep at 75°C; in this example, the ratio of composite whitening active substance: lipid material is 0.22:1;

[0025] C. take the ratio of emulsifier and distilled water mass ratio of 0.11:1 to weigh 12.0g polyglycerol-4 stearate (POLYGLYCERYL-4 STEARATE), 4.5g sucrose stearate (SUCROSE STEARATE) and 150.0g distilled water, Put it into a beaker, heat it to 75°C, and stir to obtain a liquid water phase;

[0026] D. Mix...

Embodiment 2

[0029] A preparation method of composite whitening lipid nanoparticle emulsion adopts the following steps:

[0030] A. Weigh 9.0g hydrogenated soybean oil (HYDROGENATED SOYBEAN OIL) and 13.0g stearic acid monoglyceride (GLYCERYL STEARATE) in a beaker and heat in a water bath at 85°C to obtain a liquid oil phase;

[0031] B. Weigh 2.8g tetrahydrocurcumin, 0.9g licorice root extract, 0.3g tetrahydropiperine in a ratio of 9.3: 3: 1, add them to the above-mentioned liquid oil phase, and control the stirring speed to be 500rpm, stir for 5 minutes, stir and mix evenly, and keep at 85°C; in this example, the ratio of complex whitening actives: lipid material is 0.182:1;

[0032] C. Take the ratio of emulsifier and distilled water mass ratio of 0.16:1 to weigh 12g steareth-2 (STEARETH-2), 6.8g ceteth-10 (CETETH-10), 3.5g isohard Stearyl ether-20 (ISOSTEARETH-20), 1.2g ceteareth-40 (CETEARETH-40), 0.5g steareth-100 (STEARETH-100), 150.0g distilled water, put in In a beaker, heat to 8...

Embodiment 3

[0036] A preparation method of composite whitening lipid nanoparticle emulsion adopts the following steps:

[0037] A. Weigh 18g MURUMURU SEED BUTTER, 7.8g hydrogenated soybean oil (YDROGENATED SOYBEAN OIL), 4.6g hydrogenated sweet almond oil (HYDROGENATED SWEET ALMOND OIL), 4.6g hydrogenated wheat germ oil ( HYDROGENATED WHEAT GERM OIL) and 15.0 g of GLYCERYL STEARATE were placed in a beaker and heated in a water bath at 80°C to obtain a liquid oil phase;

[0038] B. According to the ratio of 15.6: 12.4: 1, take by weighing 7.8g tetrahydrocurcumin, 6.2g licorice root extract, 0.5g tetrahydropiperine, add it to the above-mentioned liquid oil phase, control the stirring speed at 500 rpm, stir for 5 minutes, stir and mix evenly, and keep at 80 ° C; in this example, the complex whitening active substance: lipid material = 0.29: 1;

[0039] C. Take the ratio of emulsifier and distilled water mass ratio of 0.155:1, weigh 5.6g polyglycerol-2 isostearate (POLYGLYCERYL-2 ISOSTEARATE)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com