Method for obtaining high-adhesion nano coating and device thereof

A nano-coating and high-adhesion technology, applied in the direction of pressure inorganic powder coating, etc., can solve the problems that the residual tensile stress of the coating cannot be completely eliminated, hindered, and the adhesion between the coating and the substrate cannot be improved, and the residual tensile stress can be eliminated. Stress, improved mechanical properties, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

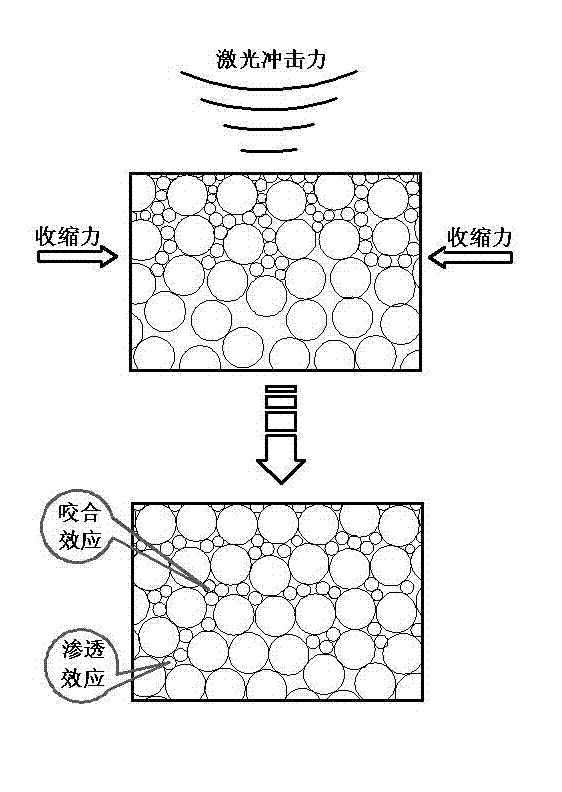

[0039] like figure 2 shown.

[0040] A method of obtaining high-adhesion nano-coatings, through the occlusal effect and penetration effect between the coating and the substrate, combined with ultra-low temperature and constant high pressure to hinder extrusion, the adhesion between the coating and the substrate is fundamentally improved. At ultra-low temperatures, the substrate will Severe shrinkage, the laser-induced impact force hinders the movement of the substrate from extruding the coating, causing the coating and the substrate to shrink under constant high pressure, which eventually leads to a more compact combination of coating atoms and substrate atoms, and the occurrence of occlusal effects and penetration effects, from Fundamentally significantly improve the adhesion of the coating to the substrate, such as figure 2 . It includes the following steps:

[0041] A) Place the workpiece 22 coated with a layer of nano powder 21 and the black paint protective layer 20 ...

Embodiment 2

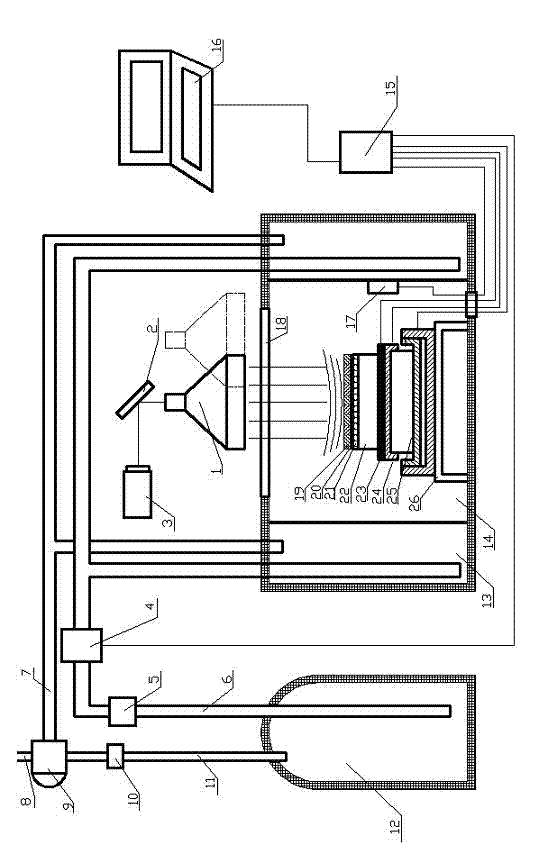

[0058] like figure 1 , 3 shown.

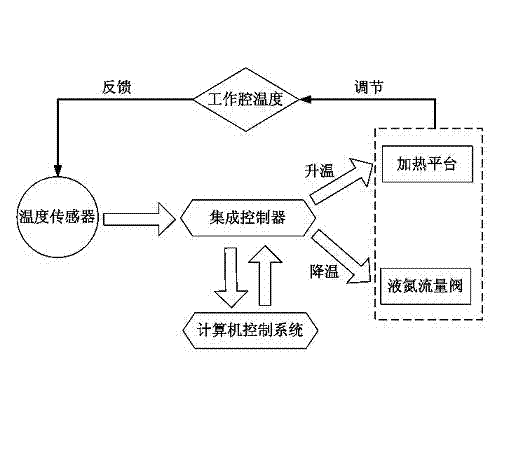

[0059] A device for obtaining high-adhesion nano-coatings, including a laser-induced shock system, a cryogenic treatment system, an auxiliary control system, an adjustable workbench, and a heating platform.

[0060] The laser shock system includes a laser 3 , a mirror 2 , a laser beam expander 1 , a high-pressure resistant glass 18 , a constrained layer 19 and a black paint 20 . Wherein, the laser 3 is arranged above the working chamber 14, and the laser beam expander 1 is clamped by a horizontally moving manipulator: when the laser-induced impact produces a coating, the manipulator clamps the laser beam expander 1 away from the laser light path ( figure 1 shown by the dotted line in the middle); when laser-induced shock treatment of the coating, the manipulator holds the laser beam expander 1 at the center of the laser light path ( figure 1 Middle solid line position), the spot area of the beam emitted by the laser 3 after passing throug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal stress | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com