Metal nanoparticle composite and process for production thereof

A technology of metal particles and manufacturing methods, applied in metal material coating process, device for coating liquid on the surface, liquid chemical plating, etc., to achieve the effect of easy adjustment and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0048] First, the metal microparticle composite and its manufacturing method according to the first embodiment of the present invention will be described.

[0049]

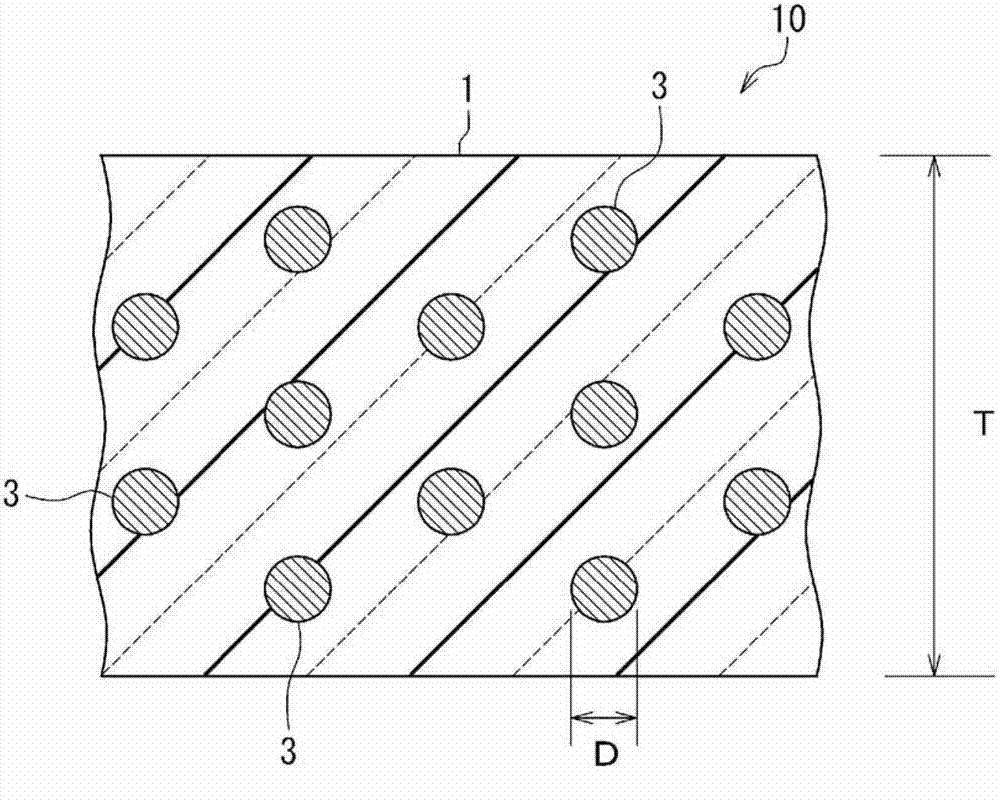

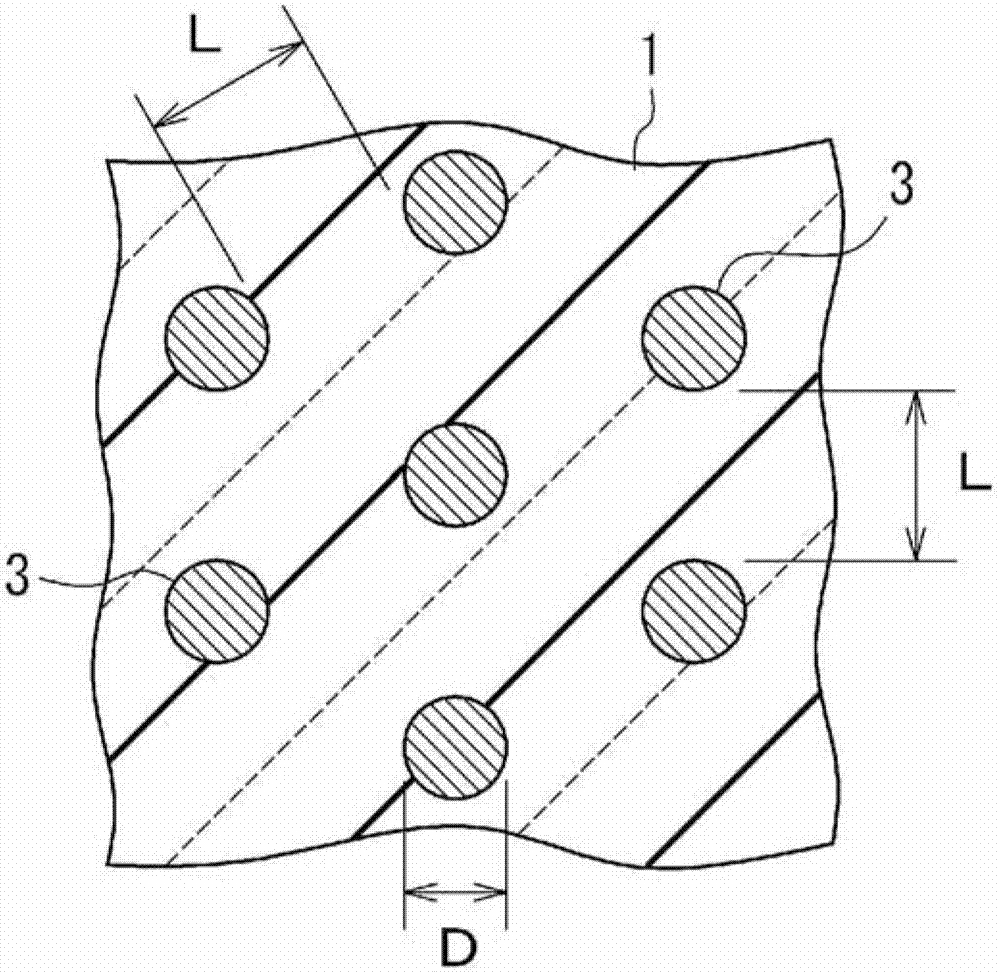

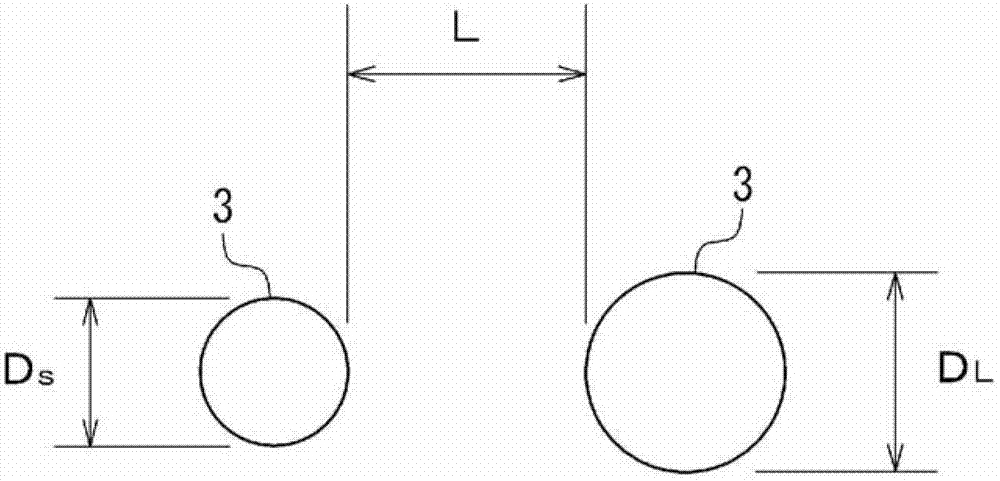

[0050] figure 1 A cross-sectional structure in the thickness direction of a metal microparticle-dispersed nanocomposite (hereinafter also simply referred to as "nanocomposite") 10 as the metal microparticle composite of the present embodiment is schematically shown. The nanocomposite 10 includes a matrix resin layer 1 and metal fine particles 3 immobilized in the matrix resin layer 1 . figure 2 Schematically shows the cross-sectional structure of the surface direction of the nanocomposite 10, image 3 It is an enlarged view illustrating the metal microparticles 3 . In addition, in image 3 , the particle size of the larger metal particle 3 among the adjacent metal particles 3 is expressed as D L , the particle size of the smaller metal particle 3 is expressed as D S , but when the two are not distinguished...

no. 2 Embodiment approach

[0159] Next, a second embodiment of the present invention will be described in detail. The method for producing a metal particle composite in this embodiment is to produce metal particles in which metal particles having an average particle diameter in the range of 20 nm to 30 nm are dispersed independently (preferably completely independently) without contacting each other in a polyimide resin. The method of the composite includes the following steps A and B. Here, the polyimide resin is a resin mainly composed of a polyimide resin obtained by imidating a polyamic acid resin which is a precursor thereof by heating to cause dehydration and a cyclization reaction. Polyimide resins are preferably used because they are superior in heat resistance and dimensional stability compared to other synthetic resins such as thermosetting resins such as epoxy resins, phenol resins, and acrylic resins. In addition, it is also advantageous that the polyimide resin has heat resistance at a tem...

Embodiment

[0193] Next, the present invention will be specifically described by way of examples, but the present invention is not limited by these examples. In addition, in the examples of the present invention, unless otherwise specified, various measurements and evaluations were performed as follows.

[0194] [Measurement of average particle diameter of metal fine particles]

[0195] For the measurement of the average particle diameter of the metal fine particles, the cross section of the sample was made into ultrathin sections using a microtome (manufactured by Leica Corporation, ULTRACUT UTC ultramicrotome), and a transmission electron microscope (TEM; manufactured by JEOL Ltd., JEM -2000EX) for observation. Moreover, since it is difficult to observe the sample produced on the glass substrate by the said method, the observation was performed using the sample produced on the polyimide film under the same conditions. In addition, the average particle diameter of a metal fine particle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com