Method and equipment for producing high-fat glycoprotein feed

A high-fat glycoprotein, feed technology, applied in feed, animal feed, animal feed and other directions, can solve the problems of material temperature rise, many impurities, long time sticking and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

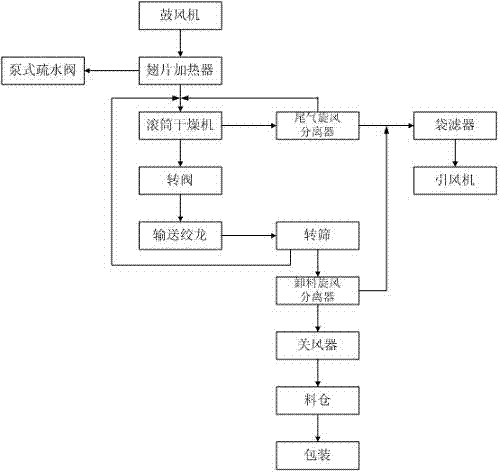

[0026] like figure 1 The present invention shown includes blower, fin heater, pump trap, scraper conveyor, drum dryer, rotary valve, conveying auger, rotary screen, unloading cyclone separator, air shutoff device, silo, tail gas Composed of cyclone separator, bag filter and induced draft fan.

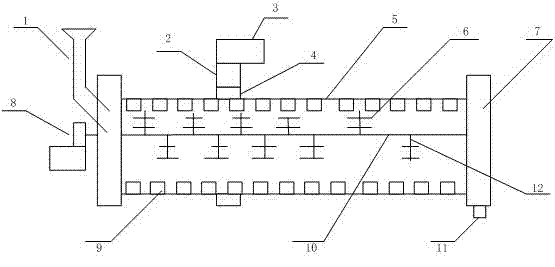

[0027] like figure 2 The drum dryer shown includes feed inlet 1, hard gear reducer 2, dryer main motor 3, meshing ring gear 4, drum dryer host 5, crushing hammer plate 6, exhaust gas collector 7, crushing reducer 8, shovel Plate 9, crushing device main shaft 10, feeding port 11, broken rib plate 12.

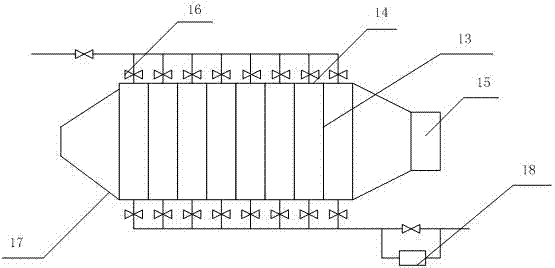

[0028] like image 3 The finned heater shown includes a finned heating pipe 13, a pressure pipe 14, an air inlet filter 15, a valve 16, an air outlet 17, and a steam trap (pump valve type) 18.

[0029] like figure 1As shown, the blower is connected to the fin heater through the air pipe to increase the drying medium for the drying system; the fin heater is connected to the pump tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com