Preparation method of monodisperse large-particle size crosslinked polymethyl methacrylate (PMMA) microspheres

A large particle size, monodisperse technology, applied in the preparation of monodisperse large particle size cross-linked PMMA microspheres, can solve the problems of small particle size and no cross-linking degree of microspheres, and achieve large particle size and cross-linking degree. Adjustable, easily available effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

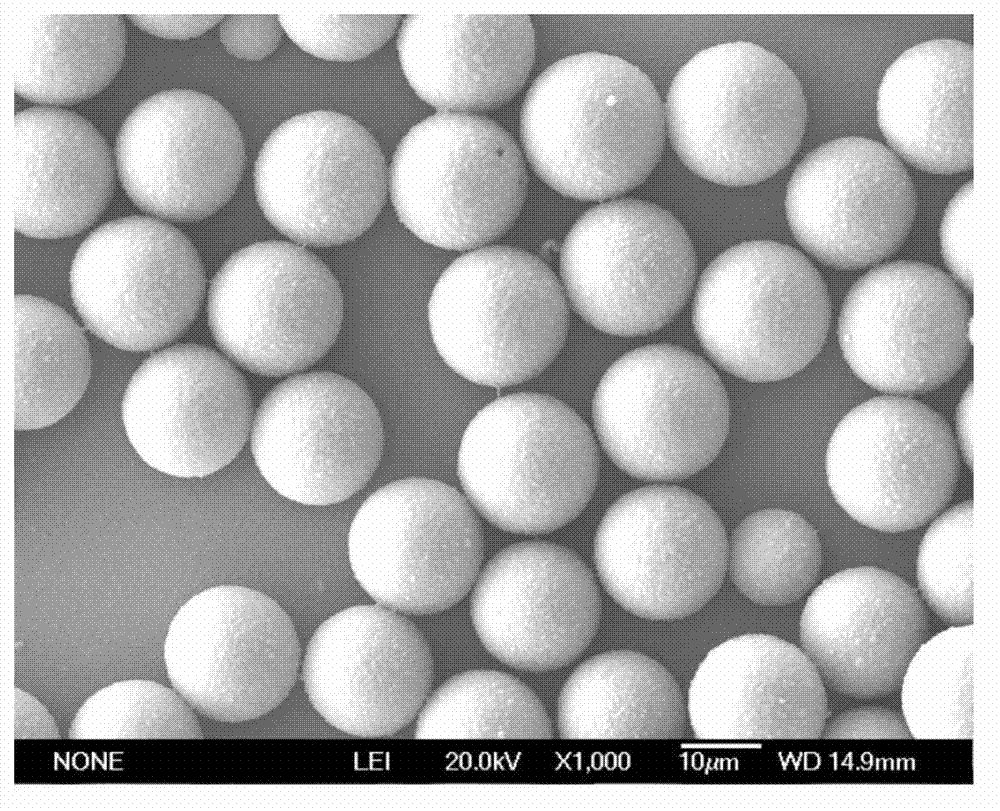

[0029] Weigh 1.0 g of PMMA seed balls with a particle size of 8.3 μm and 45 mL of 0.2% SDS solution in a beaker until fully dispersed, and add them to a four-neck flask equipped with mechanical stirring, condenser, nitrogen gas inlet and outlet, and heating jacket; in another Weigh 1.5g of cyclohexane and 90mL of 0.2% SDS solution into the beaker and ultrasonicate until a stable emulsion is formed, then add it to the above-mentioned four-neck flask; gradually raise the temperature to 35°C, and swell for 18h to activate the PMMA seed balls; weigh 0.1 g AIBN, 2.0g MMA and 2.0g EGDMA, after shaking and dissolving, add 90mL of 0.2% SDS solution and sonicate until a stable emulsion is formed, add it to the above-mentioned four-necked bottle, and carry out monomer swelling for 25h; add 3% PVP aqueous solution to the above-mentioned four-necked bottle In the mouth bottle, insert the nitrogen inlet under the liquid phase, replace the air for 30 minutes, then lift the nitrogen inlet int...

Embodiment 2

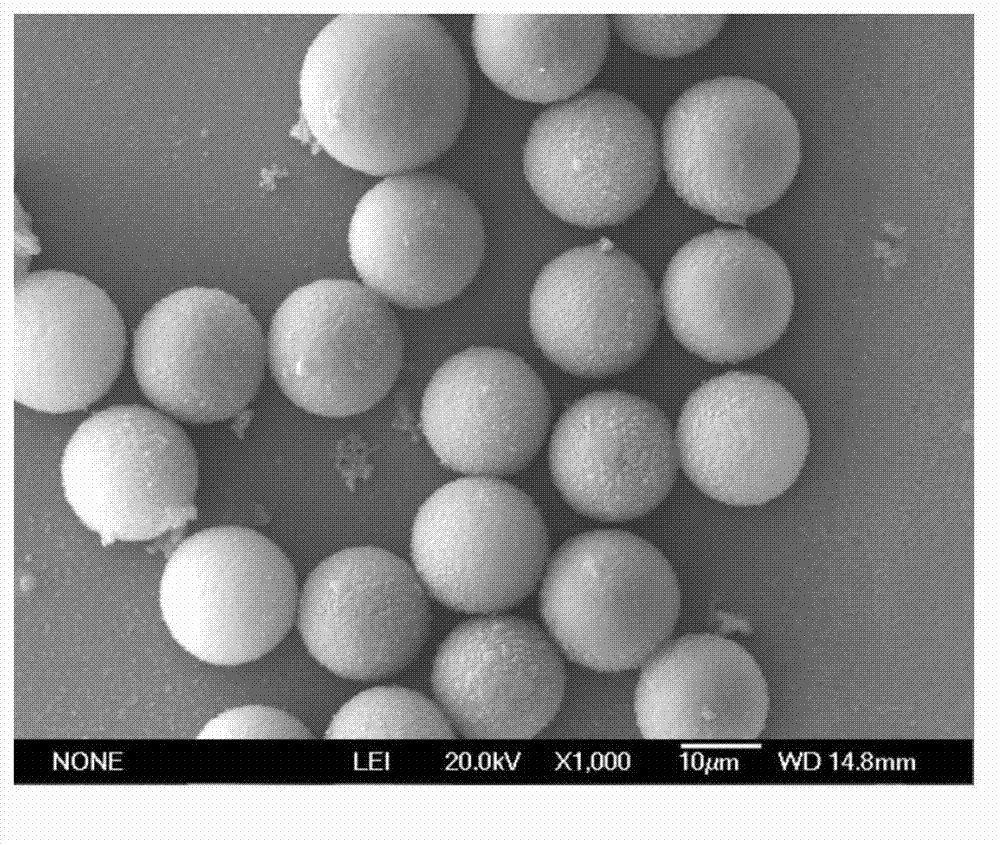

[0032] Weigh 1.0 g of PMMA seed balls with a particle size of 12.2 μm and 45 mL of 0.3% SDS solution in a beaker until fully dispersed by ultrasonication, and add them to a four-necked flask equipped with mechanical stirring, condenser, nitrogen gas inlet and outlet, and heating jacket; Weigh 1.5g of EM-221 and 90mL of 0.3% SDS solution into a beaker and ultrasonicate until a stable emulsion is formed, then add it to the above-mentioned four-neck flask; gradually raise the temperature to 35°C, and swell for 18 hours to activate the PMMA bulbs; weigh into the beaker 0.1g AIBN, 2g MMA and 1.5g EGDMA, after shaking and dissolving, add 90mL of 0.3% SDS solution and sonicate to form a stable emulsion, add it to the above four-neck bottle, and carry out monomer swelling for 25h; add 3% PVP aqueous solution to the above four-necked bottle In the mouth bottle, insert the nitrogen inlet under the liquid phase, replace the air for 30 minutes, then lift the nitrogen inlet into the gas pha...

Embodiment 3

[0035] Weigh 1.0 g of PMMA seed balls with a particle size of 18.5 μm and 45 mL of 0.2% SDS solution in a beaker until fully dispersed, and add them to a four-necked flask equipped with mechanical stirring, condenser, nitrogen inlet and outlet, and a heating jacket; Weigh 1.5g of toluene and 90mL of 0.2% SDS solution into a beaker and ultrasonicate until a stable emulsion is formed, then add it to the above-mentioned four-neck flask; gradually raise the temperature to 35°C, and swell for 18 hours to activate the PMMA seed balls; weigh 0.1g of AIBN into the beaker , 2.0g MMA and 1.5g EGDMA, after shaking and dissolving, add 90mL of 0.2% SDS solution to ultrasonic to form a stable emulsion, add it to the above four-necked bottle, and carry out monomer swelling for 25h; add 3% PVP aqueous solution to the above-mentioned four-necked bottle In the process, insert the nitrogen inlet into the liquid phase, replace the air for 30 minutes, then lift the nitrogen inlet to the gas phase a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com