Heat vulcanization bonding technology for fluorine rubber and silica gel

A technology of thermal vulcanization and fluorine rubber, which is applied in the field of rubber manufacturing, can solve the problems of unsatisfactory peel strength and high cost, and achieve the effects of meeting actual production needs, realizing industrialized production, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

[0022] A heat vulcanization bonding process of fluorine rubber and silica gel. The process uses a bonding composition to be rolled into a thin sheet, and is placed between the inner layer of fluorine rubber and silica gel to form a semi-finished product of the inner layer of fluorine rubber, bonding composition and silica gel structure, and then Heat vulcanization to bond and fix the inner layer of fluorine rubber and silica gel. The process conditions for heat vulcanization are: wrap the outer surface of the semi-finished product with rubber hose, use cellophane or nylon tape to pressurize, and the vulcanization parameter is 170°C / 30 minutes; The vulcanization parameters are 160-170°C / 10-15 minutes.

[0023] The inner layer of fluorine rubber is mixed with the components shown in Table 1.

[0024] Table 1 (unit: kg)

[0025] Example Components 1 2 3 4 5 Fluorine rubber FKM-DS2601 100 100 100 100 100 Activated Magnesium Oxide 10 10 8 8 9 ...

Embodiment 6

[0030] The specific scheme is the same as in Example 1, except that in the bonding composition, the weight ratio of the inner layer of fluorine rubber, silica gel and fluorine-based coupling agent F-1 is 3.8:4.6:1.

Embodiment 7

[0032] The specific scheme is the same as in Example 1, except that in the bonding composition, the weight ratio of the inner layer of fluorine rubber, silica gel and fluorine-based coupling agent F-1 is 4.2:5.5:1.

[0033]

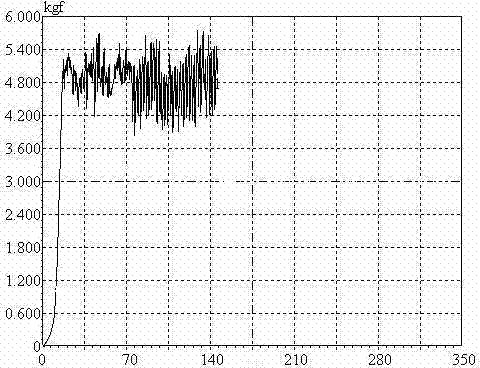

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com