Method for extracting roselle calyx red pigment

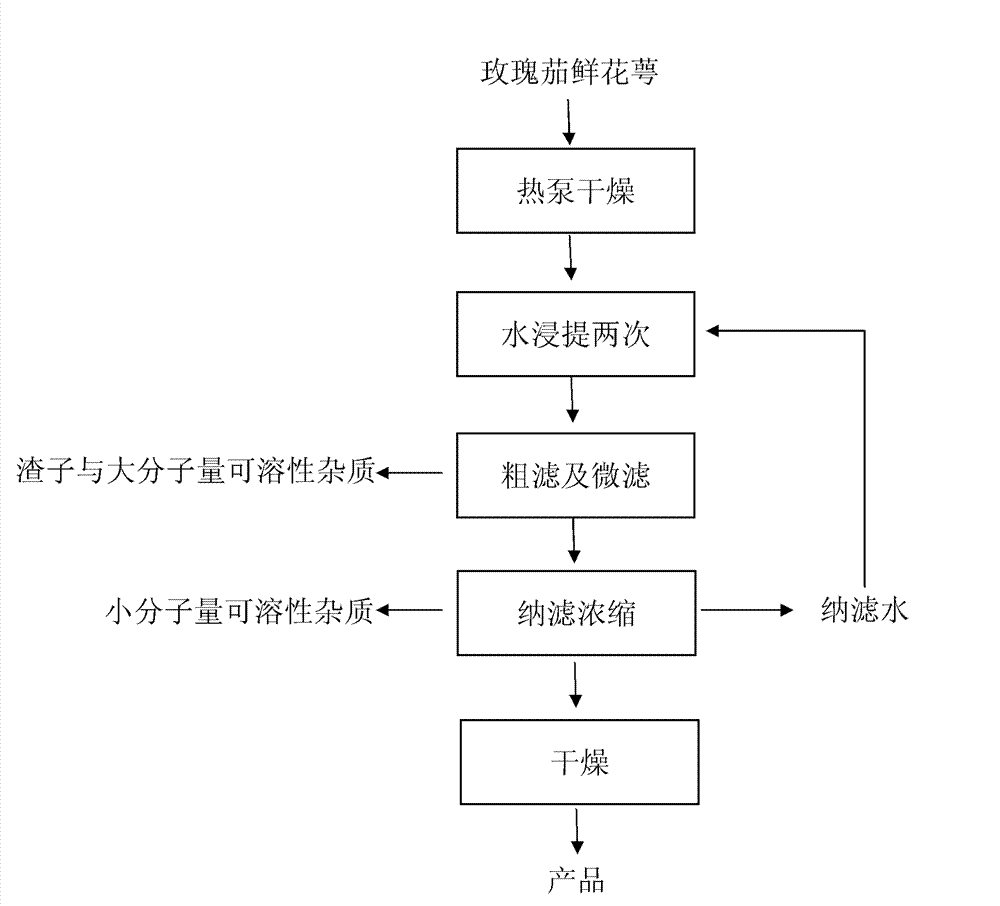

An extraction method, the technology of roselle red, is applied in the field of extraction of natural plant pigments, which can solve the problems of reduced utilization rate of raw materials, mildew, fading, and damage of raw materials, and achieve the effects of low cost, obvious energy saving effect, and improved utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Take 100kg fresh roselle calyx as material, dehydrate 5 hours at 45-50°C by heat pump to obtain 36kg dried roselle calyx (water content is 16%-18%); heat 720kg of water to 50-60°C, and then dry The calyx is completely soaked in it, and the temperature is maintained for 1 hour, and the extraction is performed twice. The water used for the second extraction includes the water obtained by the subsequent nanofiltration; 0.1-0.2Mpa polyamide roll-type microfiltration membrane is refined to remove pectin and other macromolecular soluble impurities, and the TFM nanofiltration membrane with a molecular weight cut-off of 600-800 and a working pressure of 0.7-0.8Mpa is concentrated to further remove small molecules of organic acids, Sugar, inorganic ions, and other residual impurities were obtained to obtain 68 kg of roselle red pigment concentrate, which was then spray-dried. The air inlet temperature was 180° C., and the air outlet temperature was 85-95° C. After drying, 6.8 kg ...

Embodiment 2

[0022] 200 kg of fresh roselle calyxes were used as materials, and dehydrated by a heat pump at 45-50° C. for 6 hours to obtain 72 kg of roselle dried calyxes (with a water content of 16%-18%). Heat 1440kg of water to 50-60°C, then soak all the dried calyx in it, maintain the temperature for 1 hour, and extract twice, and the water used for the second extraction includes the water obtained by nanofiltration; it is removed by bag filtration Foreign matter, the polyamide roll-type microfiltration membrane with a molecular weight cut-off of 80,000-100,000 and a working pressure of 0.1-0.2Mpa is refined to remove macromolecular soluble impurities such as pectin. TFM nanofiltration membrane concentration further removes residual impurities such as small molecule organic acids, sugars, inorganic ions, etc. to obtain 140kg of roselle red pigment concentrate, which is then spray-dried. The temperature of the air inlet is 180°C, and the temperature of the air outlet is 85-95°C After dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com