Method utilizing microwave assisted lipase catalysis to synthesize esterification modified EGCG

An esterification modification and microwave-assisted technology, which is applied in the field of biosynthesis of organic compounds, can solve the problems of introducing too many solvents, many reaction steps, and long time consumption, so as to speed up the reaction speed, increase the reaction yield, and shorten the reaction time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Add 50 mg of EGCG and 9.5 mL of vinyl acetate into a 50 mL round-bottomed flask with a stopper (the molar ratio of EGCG and vinyl acetate is 1:1), then add 20 mL of isopropanol, place the reactor in a microwave reaction device, and add 80U / g EGCG lipase LIPOZYME TL IM was reacted at 40°C and 40W for 30min. After the reaction was stopped, the reaction solution was filtered, rotary evaporated, and vacuum dried to obtain 35.8mg of EGCG esterification product with a recovery rate of 71.6%. The conversion rate of EGCG was analyzed by high performance liquid chromatography to be 65.4%.

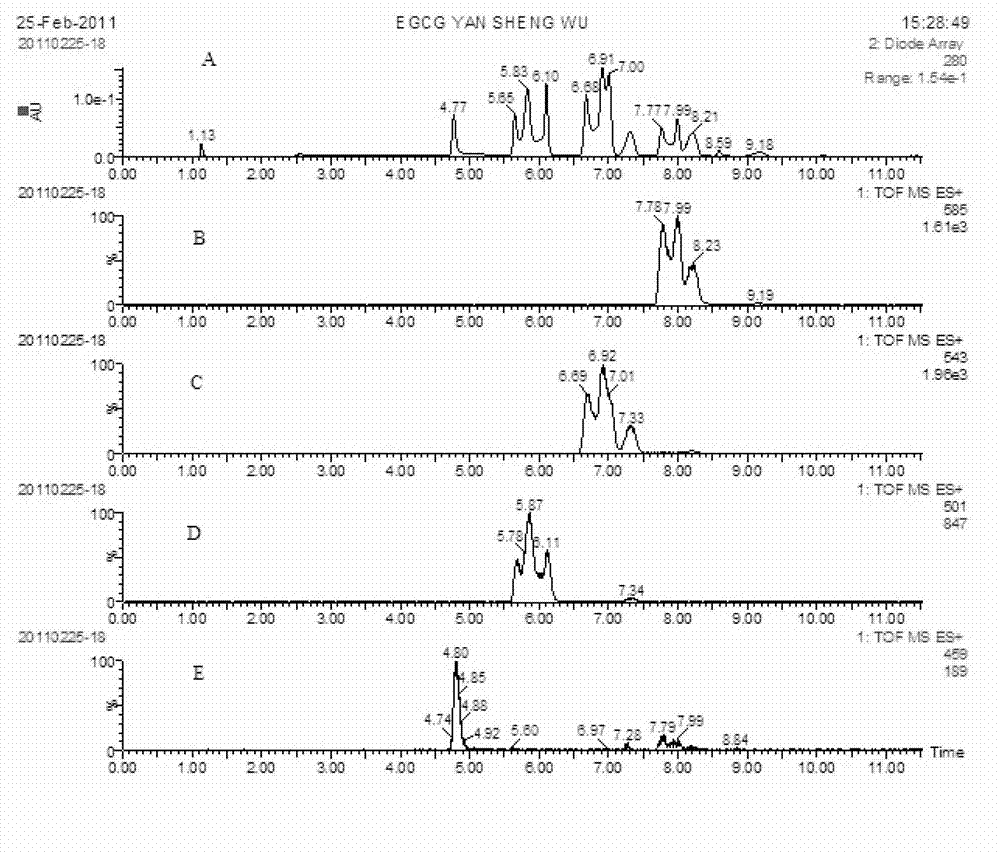

[0016] Mass spectrometry analysis of EGCG acetylation products such as figure 1 shown.

[0017] A: The liquid chromatogram of the product after the acetylation reaction at 280nm; B: The mass spectrum selected ion map of the acetylated product (Mw=585) with 3 hydroxyl groups in the EGCG molecule; C: The acetylated 2 hydroxyl groups in the EGCG molecule MS-selected ion map of product (Mw=543)...

Embodiment 2

[0021] Add 50mg of EGCG and 16.1mL of vinyl butyrate into a 50mL round bottom flask with a stopper (the molar ratio of EGCG and vinyl butyrate is 1:1), then add 20mL of isopropanol, and place the reactor in a microwave reaction device , add 100U / g EGCG lipase Lipase AYS "Amano", react at 60°C and 50W for 40min, after stopping the reaction, the reaction solution is filtered, rotary evaporated, and vacuum dried to obtain 30.8 mg of EGCG esterification product, the recovery rate is 61.6 %. The conversion rate of EGCG was analyzed by high performance liquid chromatography to be 73.4%.

Embodiment 3

[0025] Add 150 mg of EGCG and 15.6 mL of vinyl hexanoate into a 100 mL round bottom flask with a stopper (the molar ratio of EGCG and vinyl hexanoate is 1.5:1), then add 40 mL of isopropanol, and place the reactor in a microwave reaction device. Add 100U / g EGCG lipase Lipase AYS "Amano" and react at 50°C and 60W for 50min. After the reaction is stopped, the reaction solution is filtered, rotary evaporated, and vacuum dried to obtain 81.5mg of EGCG esterification product, with a recovery rate of 81.5% . The conversion rate of EGCG was analyzed by high performance liquid chromatography to be 76.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com