Electrolysis method

An electrolysis method and electrolyzer technology, applied in the electrolysis process, electrolysis components, etc., can solve the problems of reducing the efficiency of electrolytic metal powder and consuming labor costs, etc., and achieve the effect of high current utilization rate and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

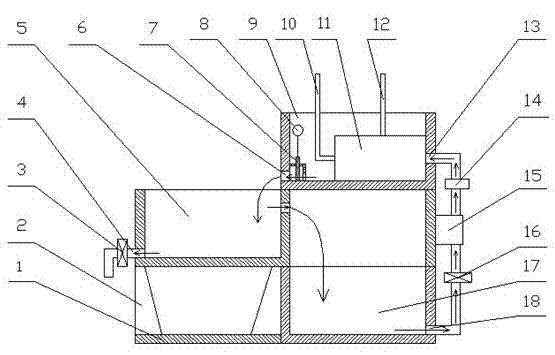

[0019] Embodiment 1: In this embodiment, zinc powder is electrolyzed. On the basis of the traditional electrolysis method, one of the electrodes is changed to a cylindrical shape, and the other electrode is placed inside the cylindrical shape to form an electrolyzer, and then the electrolyzer is Put it in an electrolytic cell, use zinc sulfate heptahydrate and ammonium sulfate solution, adjust the pH value with ammonia water, and perform electrolysis in an alkaline environment with a current density of 850A / ㎡. Cylindrical aluminum is used as the cathode electrode, and rod-shaped graphite is used as the anode electrode. The distance between the cathode and anode electrodes is 30mm, forming a concentric shaft shape with an axial length of 180mm. The electrolyte continuously enters the electrolytic cell from the axial direction of the cylindrical electrolyzer, and the water pressure of the circulating electrolyte entering the electrolyzer is 0.0006MPa, and the electrolysis is comp...

Embodiment 2

[0020] Example 2: In this example, iron powder is electrolyzed. On the basis of the traditional electrolysis method, one of the electrodes is changed to a cylindrical shape, and the other electrode is placed inside the cylindrical shape to form an electrolyzer, and then the electrolyzer is Put it into the electrolytic cell, use highly polished stainless steel as the cathode, and low-carbon steel as the anode, and their materials can be ferrous metal waste, such as rolled steel scale, low-grade ore, steel, cast iron, sponge iron briquettes, etc., the electrolyte for chloride. Adjust the pH with industrial ammonia. The current density during electrolysis is 2.8A / dm 2 , Heteropolar spacing is 50mm. The electrolyte continuously enters the electrolyzer from the axial direction of the cylindrical electrolyzer, and the water pressure when the circulating electrolyte enters the electrolyzer is 5PMa. The particle size of the electrolyzed iron powder is below 14um.

Embodiment 3

[0021] Embodiment 3: In this embodiment, nickel powder is electrolyzed. On the basis of the traditional electrolysis method, one of the electrodes is changed into a cylinder, and the other electrode is placed inside the cylinder to form an electrolyzer, and then the electrolyzer is Put it into the electrolytic cell, and the electrolyte is made of nickel sulfate and ammonium sulfate according to a certain ratio. The anode material is lead-silver alloy, and the cathode material is titanium metal. The current density is 2000A / ㎡, and the distance between different plates is 50mm. The electrolyte continuously enters the electrolyzer from the axial direction of the cylindrical electrolyzer, and the water pressure when the circulating electrolyte enters the electrolyzer is 3.5MPa. The particle size of the electrolytic nickel powder is less than 9.3um.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com