Probe inserting device of scanning probe microscope and method thereof

A technology of scanning probe and microscope, which is applied in the direction of scanning probe technology and instruments, can solve the problems of complex structure, low environmental adaptability and inconvenient operation of SPM rapid needle insertion device, and achieve simple structure, low cost and easy operation. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

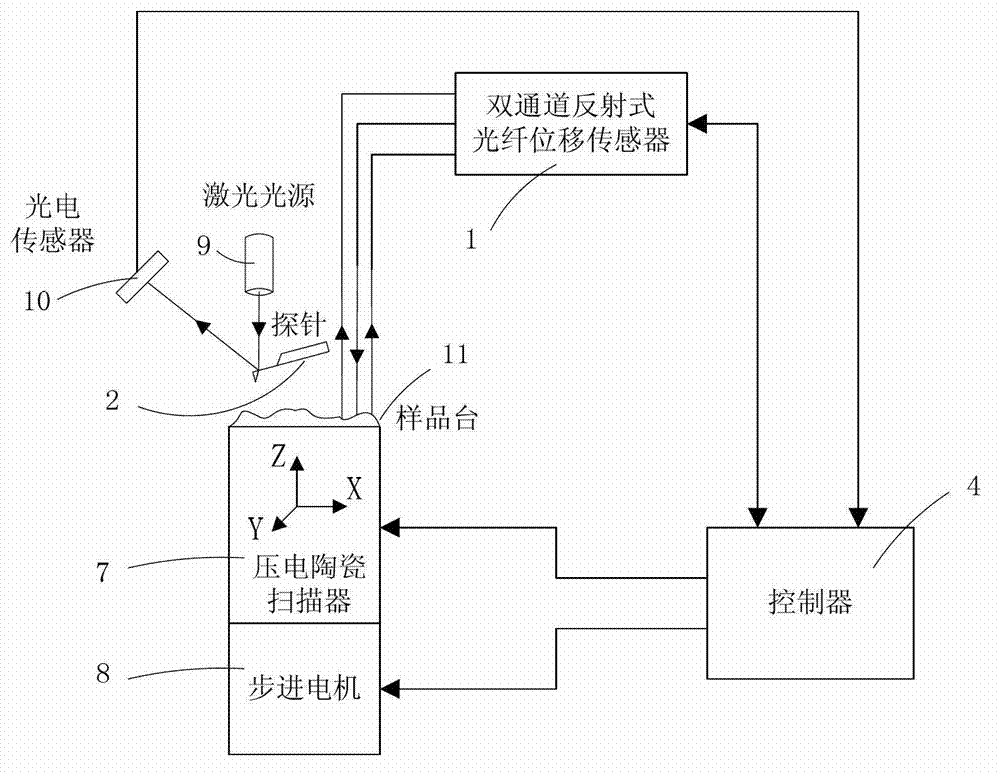

[0029] Such as figure 1 As shown, the device of the present invention includes a controller 4 , a stepper motor 8 , a piezoelectric ceramic scanner 7 , a laser light source 9 , a photoelectric sensor 10 , a probe 2 and a dual-channel reflective optical fiber displacement sensor 1 . The controller 4 is electrically connected with the stepper motor 8 , the piezoelectric ceramic scanner 7 , the laser light source 9 , the photoelectric sensor 10 and the dual-channel reflective optical fiber displacement sensor 1 . The stepper motor 8 is fixed on the base of the scanning probe microscope needle insertion device in a direction perpendicular to the horizontal plane, and the stepper motor 8 is connected to the piezoelectric ceramic scanner 7 through a screw. The piezoelectric ceramic scanner 7 can carry out micro-displacement motions in X, Y, and Z directions. A sample stage 11 is set on the piezoelectric ceramic scanner 7 . The probe 2 is installed on the probe base 3 and rigidly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com