Manufacturing method for soft magnetic core spiral micro-inductor

A manufacturing method and technology of spiral inductors, which are applied in the field of microelectronics, can solve problems such as increased loss of micro-inductors, decreased Q value, and deteriorated inductance performance, and achieve the effect of high graphics accuracy and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

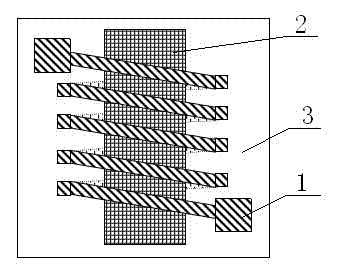

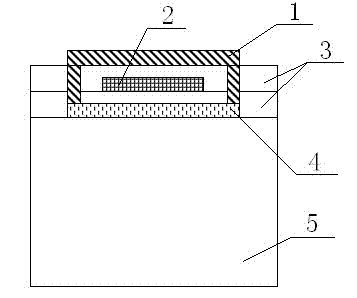

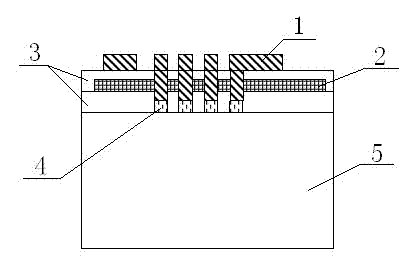

[0034] Based on the GaN HEMT (Gallium Nitride High Electron Mobility Transistor) MMIC manufacturing process, a soft magnetic core spiral micro-inductor is manufactured. The specific manufacturing process is as follows:

[0035] 1) Prepare the lower layer metal of the inductor: clean the substrate with deionized water, deposit 50 / 100 nm Ti / Au metal on the GaN substrate as the electroplating seed layer by using the sputtering process; Develop to obtain the lower-layer electroplated metal pattern, use the electroplating process to electroplate 2μm Au metal, use flood exposure and development to remove the remaining photoresist, and use wet etching to remove the remaining seed layer metal to obtain the lower metal of the spiral inductor;

[0036]2) Preparation of the first layer of benzocyclobutene BCB dielectric layer: Spin-coat the BCB medium using the uniform glue process, and use the conventional annealing process to cure the benzocyclobutene BCB, specifically: in the N2 atmosp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com