Liquid-solid mixed lipid nano-slow release system for cosmetic and preparation method thereof

A nano-sustained release and mixed lipid technology, which is applied in the field of nano-sustained-release system and its preparation, can solve the problems of unseen literature and patent reports, and achieve the effects of improved encapsulation efficiency, good compatibility, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Take 3mL of a commercially available silk peptide aqueous solution (14.5%) sample in a three-necked flask, add 15mL of 6mol L -1 HCl and 2 to 3 drops of phenol, sealed, and vacuum degassed at the same time, N 2 Sealed and protected, heated in an oil bath, hydrolyzed at 150°C for 1.5 hours, after the hydrolysis is complete, the hydrolyzed solution is rotary evaporated to dryness, and the volume is adjusted to the original volume with distilled water, shaken to obtain the silk peptide hydrolyzed solution.

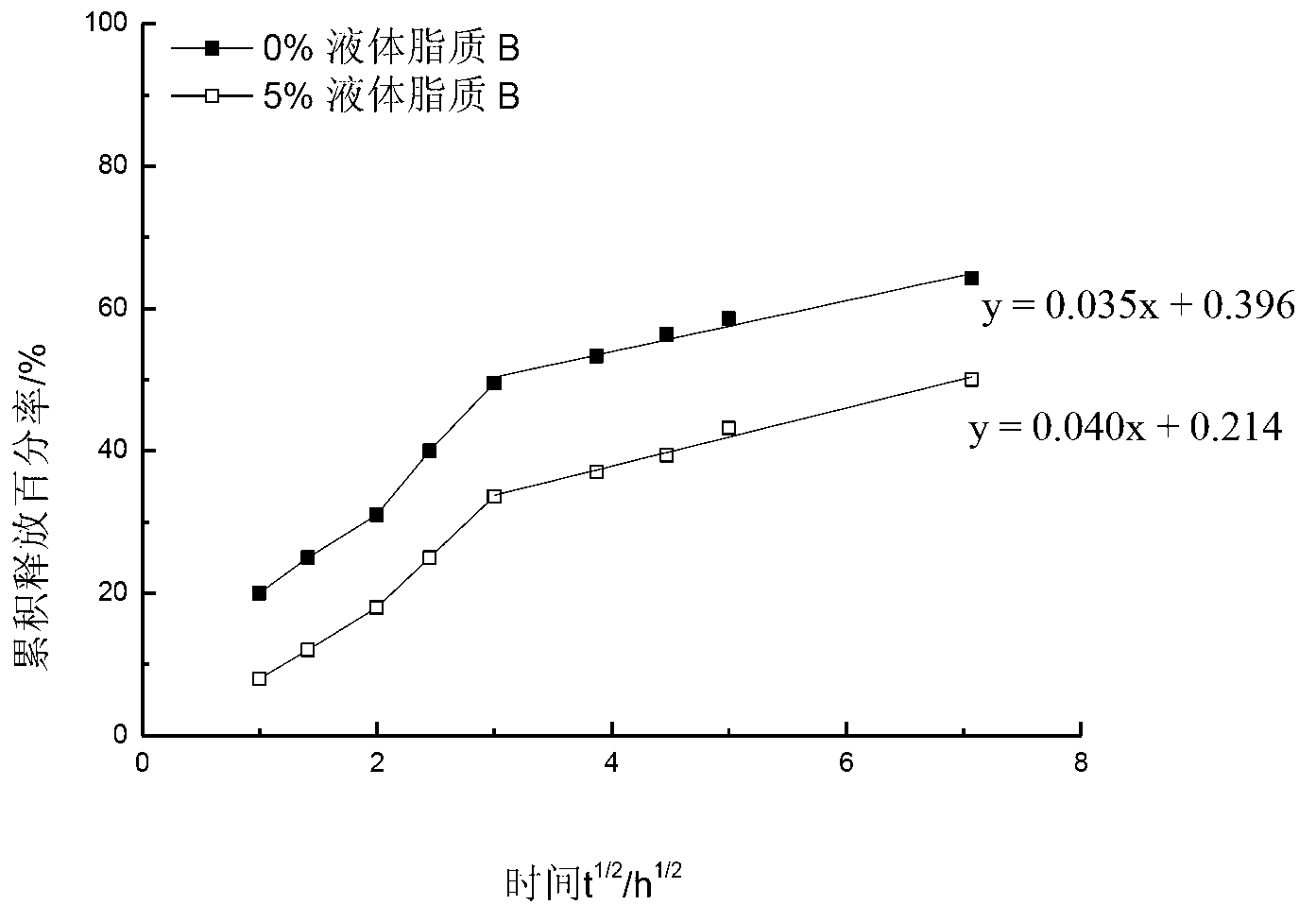

[0037] Accurately weigh 200 mg of the mixed carrier of glyceryl monostearate (solid lipid A), isopropyl myristate (liquid lipid B), and the proportion of liquid lipid B is 5% (w / w ), dispersed in 4 mL of absolute ethanol, added 0.1 mL of silk peptide hydrolyzate, and heated in a water bath at 50 ° C to promote the dissolution of solid lipids. At 400r·min -1 Under the condition of mechanical stirring, the obtained mixture solution (organic phase) was poured into 40 mL...

Embodiment 2

[0053] According to Example 1, the suspension (emulsion) of silk peptide-liquid-solid mixed lipid nanoparticles containing liquid lipid B of 5% (w / w) was prepared, denoted as 1 # ; The blank silk peptide-liquid-solid mixed lipid nanoparticle (containing liquid lipid B is 5%, but does not add silk peptide hydrolyzate when preparing according to Example 1) is ultrasonically dispersed in distilled water, and in this suspension Add the same amount of silk peptide hydrolyzate when preparing Example 1, and the gained mixed emulsion is recorded as 2 # .

[0054] Will 1 # with 2 # The emulsion was subjected to an in vitro moisturizing test (n=3) by in vitro weighing method under two different relative humidity environments, and the results are shown in Table 2.

[0055] Table 2 In vitro moisturizing test results of silk peptide-liquid-solid mixed lipid nano-sustained release system

[0056]

[0057] Table 2 shows that under low humidity (drier environment) conditions, the long-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com