Swine fever vaccine heat-resistant freeze-drying protective agent, and preparation method and application thereof

A swine fever live vaccine and heat-resistant freeze-drying technology are applied in the field of heat-resistant freeze-drying protective agent for swine fever live vaccine and its preparation, and the protective agent for live virus vaccine, which can solve the problem of poor protection function, long-term storage and transportation of finished vaccines Restrictions and other issues, to achieve the effect of simple formula, suitable for large-scale production, and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

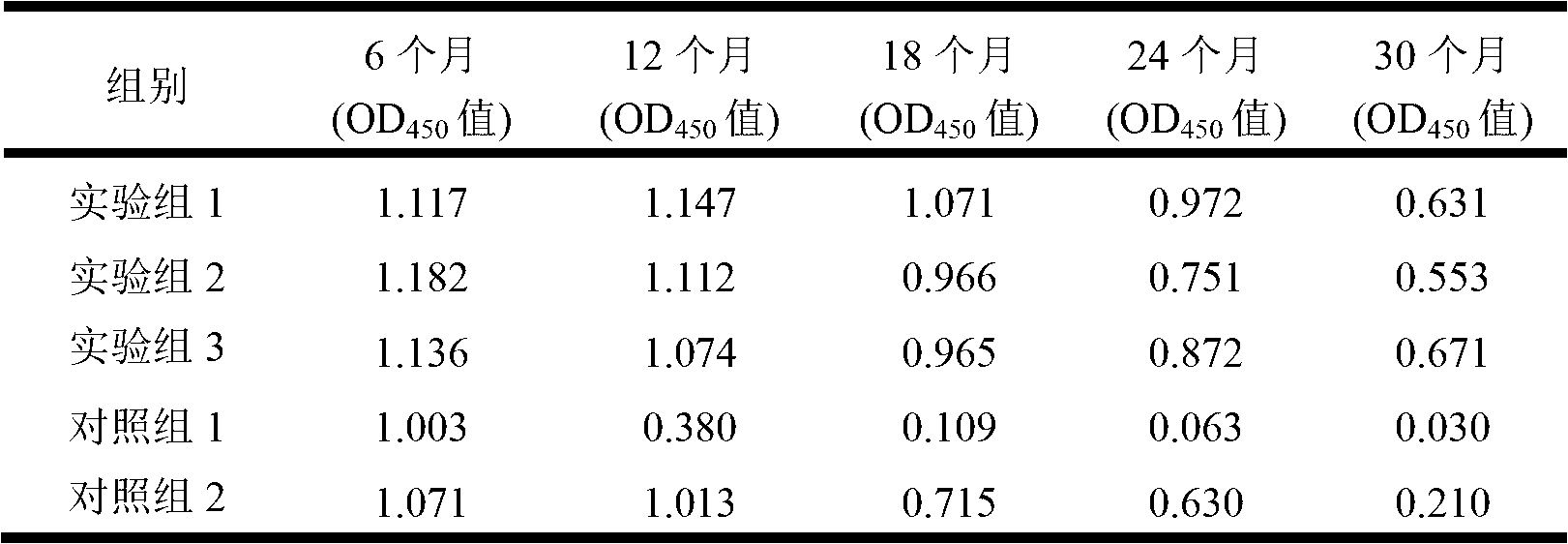

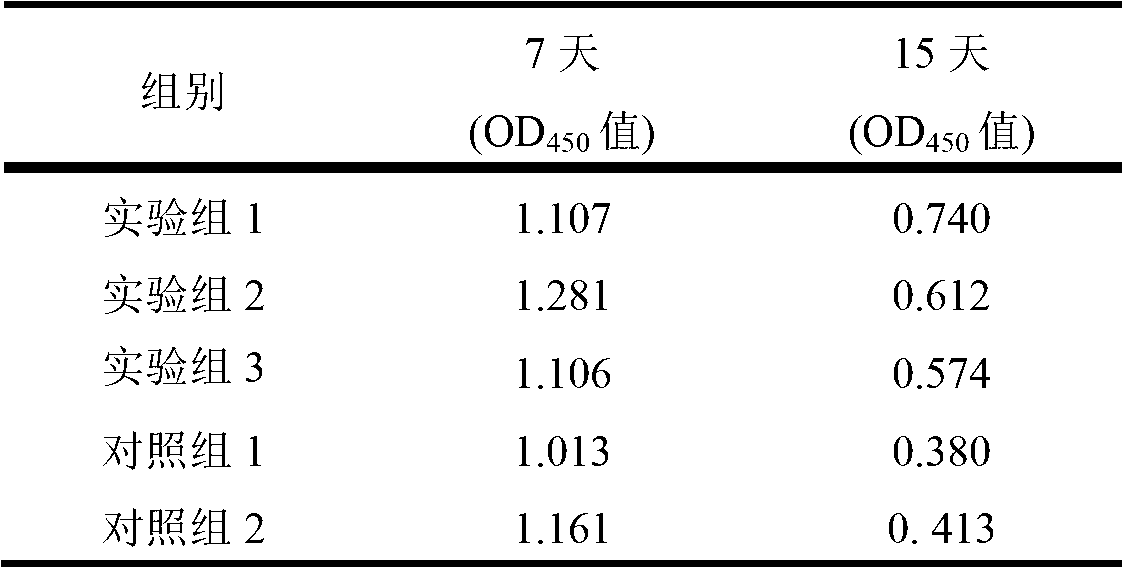

Examples

Embodiment 1

[0025] The heat-resistant lyoprotectant for swine fever live vaccine consists of the following components in weight percentage: 5% trehalose, 2% polyvinylpyrrolidone (PVP), 1% gelatin, 1% sodium glutamate, D-sorbic acid Alcohol 2%, polypeptone 4%, L-arginine 0.5%, vitamin C 0.5%, and the balance is sterilized water for injection.

[0026] The specific preparation steps of the heat-resistant lyoprotectant are:

[0027] (1) Weigh polyvinylpyrrolidone, gelatin, D-sorbitol, and polypeptone according to the weight ratio, dissolve them in a small amount of water for injection, and sterilize at 110°C for 30 minutes for later use;

[0028] (2) Weigh trehalose, sodium glutamate, L-arginine, and vitamin C according to the weight ratio, dissolve them in a small amount of water for injection, filter and sterilize them with a filter membrane with a pore size of 0.22 μm, and set aside;

[0029] (3) Mix the solutions prepared in steps (1) and (2), and add water for injection to the full amo...

Embodiment 2

[0033] The heat-resistant lyoprotectant for swine fever live vaccine consists of the following components in weight percentage: trehalose 8%, polyvinylpyrrolidone (PVP) 2.5%, gelatin 1.5%, sodium glutamate 2%, D-sorbic acid Alcohol 3.5%, polypeptone 4.5%, L-arginine 0.75%, vitamin C 0.75%, and the balance is sterilized water for injection.

[0034] The specific preparation steps of the heat-resistant lyoprotectant are:

[0035] (1) Weigh polyvinylpyrrolidone, gelatin, D-sorbitol, and polypeptone according to the weight ratio, dissolve them in a small amount of water for injection, and sterilize at 116°C for 20 minutes for later use;

[0036] (2) Weigh trehalose, sodium glutamate, L-arginine, and vitamin C according to the weight ratio, dissolve them in a small amount of water for injection, filter and sterilize them with a filter membrane with a pore size of 0.22 μm, and set aside;

[0037] (3) Mix the solutions prepared in steps (1) and (2), and add water for injection to th...

Embodiment 3

[0041] The heat-resistant lyoprotectant for swine fever live vaccine consists of the following components in weight percentage: trehalose 10%, polyvinylpyrrolidone (PVP) 3%, gelatin 2%, sodium glutamate 3%, D-sorbic acid Alcohol 5%, polypeptone 5%, L-arginine 1%, vitamin C 1%, and the balance is sterilized water for injection.

[0042] The specific preparation steps of the heat-resistant lyoprotectant are:

[0043] (1) Weigh polyvinylpyrrolidone, gelatin, D-sorbitol, and polypeptone according to the weight ratio, dissolve them in a small amount of water for injection, and sterilize at 120°C for 15 minutes for later use;

[0044] (2) Weigh trehalose, sodium glutamate, L-arginine, and vitamin C according to the weight ratio, dissolve them in a small amount of water for injection, filter and sterilize them with a filter membrane with a pore size of 0.22 μm, and set aside;

[0045] (3) Mix the solutions prepared in steps (1) and (2), and add water for injection to the full amount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com