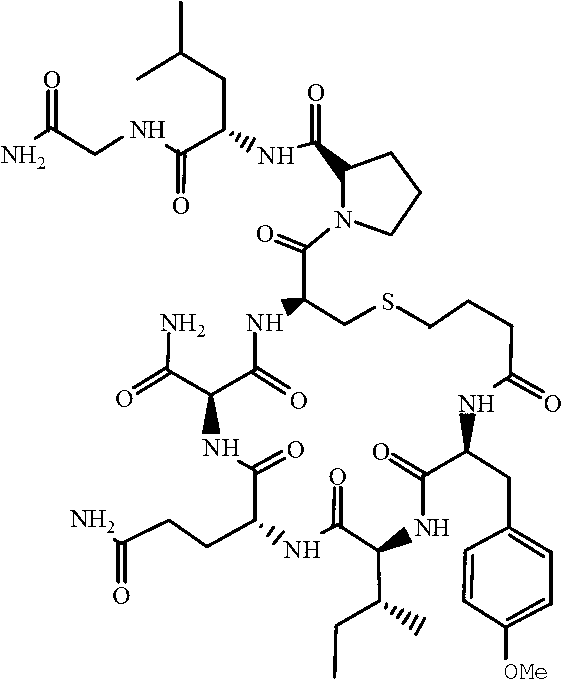

Solid-phase synthesis method of carbetocin

A technology for carbetocin and solid-phase synthesis is applied in the field of solid-phase synthesis of carbetocin, and can solve the problem of being unfavorable for large-scale production, easy to produce polymers, and removing side chain allyl protecting group reagents. Expensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

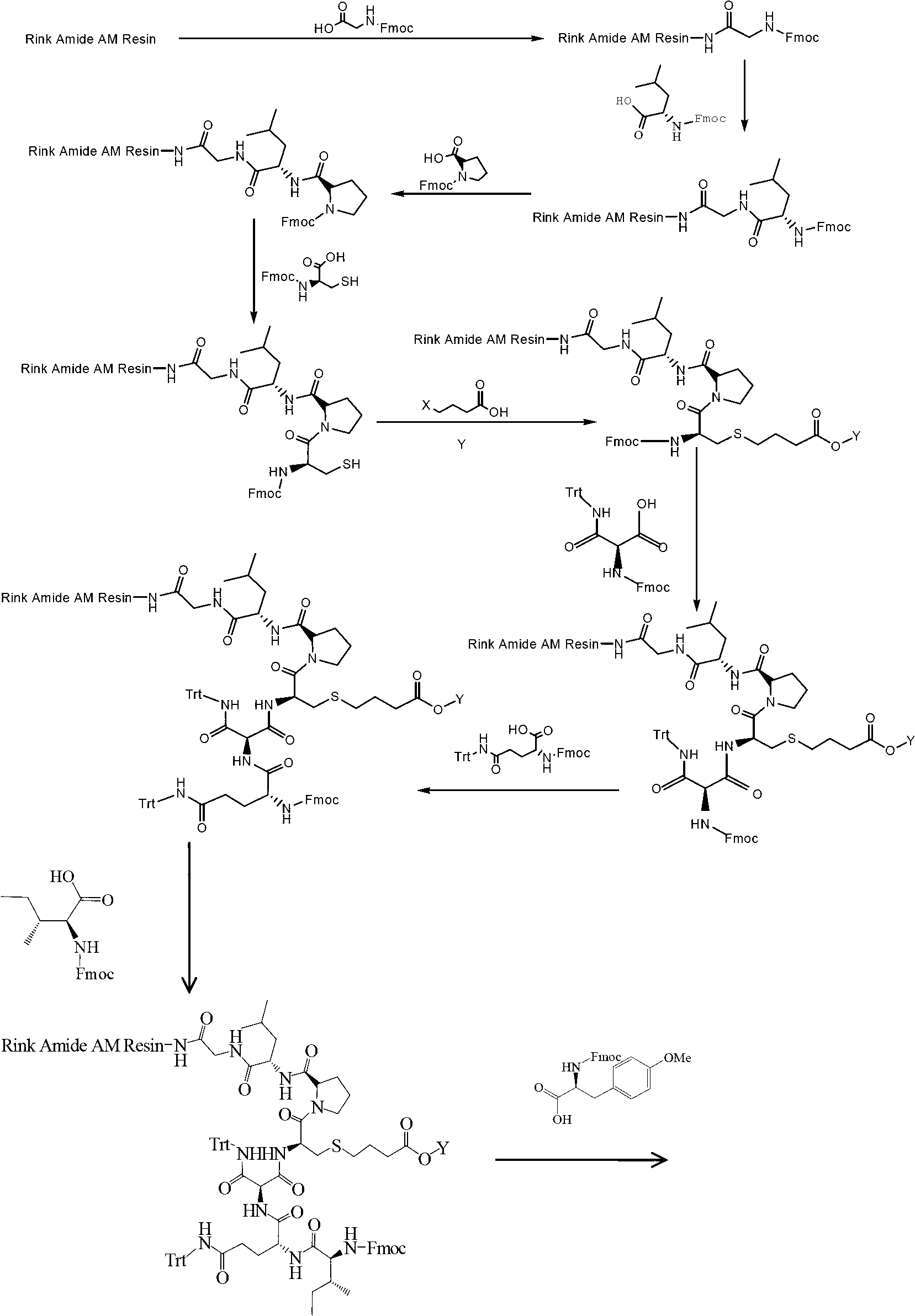

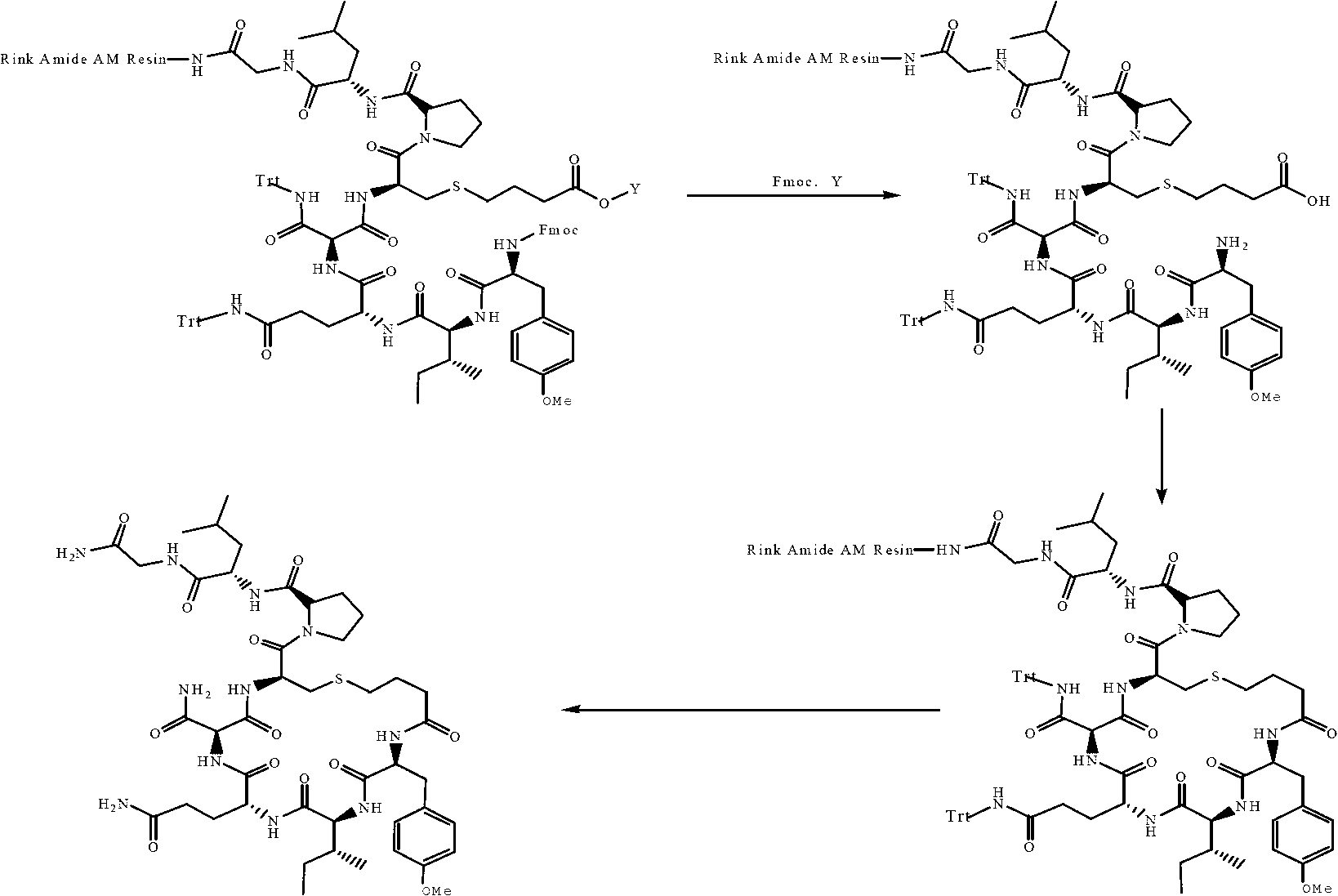

Method used

Image

Examples

Embodiment 1

[0031] Step (1) Preparation of Fmoc-Gly-Rink Amide AM Resin

[0032]Weigh 10g of Rink Amide AM Resin (100 mesh, 0.38mmol / g), soak in 50mL DCM for 30min to fully swell the resin, wash with 70mL DMF twice (not less than 1min each time), and wash with 70mL 25% piperidine / DMF Remove the Fmoc protecting group twice at 30°C, the first time is 5 minutes, the second time is 15 minutes, and the middle is washed once with 70 mL of anhydrous DMF, not less than 1 minute. Wash with 70 mL of anhydrous DMF, MeOH, DCM, and DMF successively 2, 1, 1, and 2 times, each time not less than 1 min.

[0033] Weigh 3.39g of Fmoc-Gly-OH, 1.55g of HOBt, and 1.77mL of DIC into 10mL of anhydrous DMF, and activate at 0~5°C for 5min. Add solid-phase synthesis tube and react at 30°C for 2.0~4.0h. The end point of the reaction is determined by the ninhydrin method. Wash with 70 mL of anhydrous DMF for 2 times, each time not less than 1 min, to obtain Fmoc-Gly-Rink Amide AM Resin.

[0034] Step (2) Tyr(Me)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com