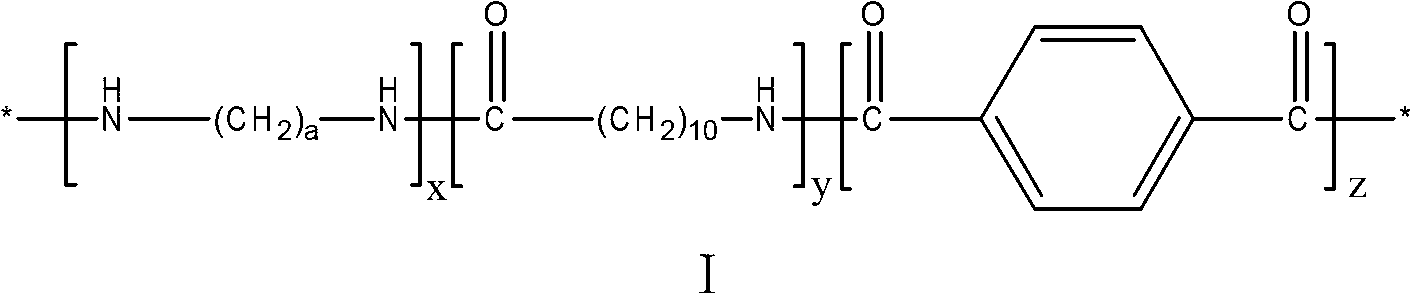

Long carbon-chain semi-aromatic polyamide and synthetic method of same

A semi-aromatic and polyamide technology, applied in the field of materials, can solve the problems that have not been reported, and achieve the effect of simple preparation process and controllable polymerization process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

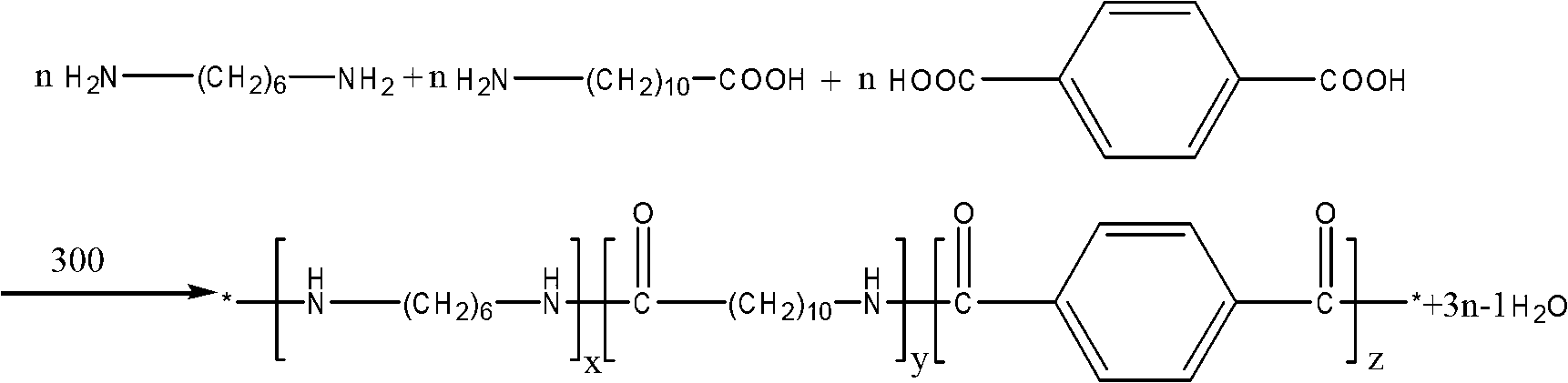

Embodiment 1

[0039] Add hexamethylenediamine, 11-aminoundecanoic acid, and terephthalic acid in the weight of 23.2kg, 40.2kg, and 33.2kg (molar ratio: 1:1:1) into the stirring polymerization reactor after vacuum drying, After evacuating for 10 minutes, pass nitrogen gas for 2 minutes, and cycle like this 6 times, so that the reactant exists in an environment under the protection of nitrogen gas, and control the system pressure in the reactor to 0.2 MPa. Seal the reactor and heat it up to 130°C, and adjust the stirring speed of the polymerization reactor to 200r / min, control the system pressure in the reactor to 1.1MPa, keep the reactant under pressure for 1 hour, and slowly release the gas to normal pressure, Reheat to 300° C., and adjust the stirring speed of the polymerization reactor to 50 r / min. After constant temperature, continue vacuuming for 8 hours, and the reaction ends. Nitrogen-filled material is discharged, cooled in a water tank, and pelletized to prepare PA11T.

[0040] The...

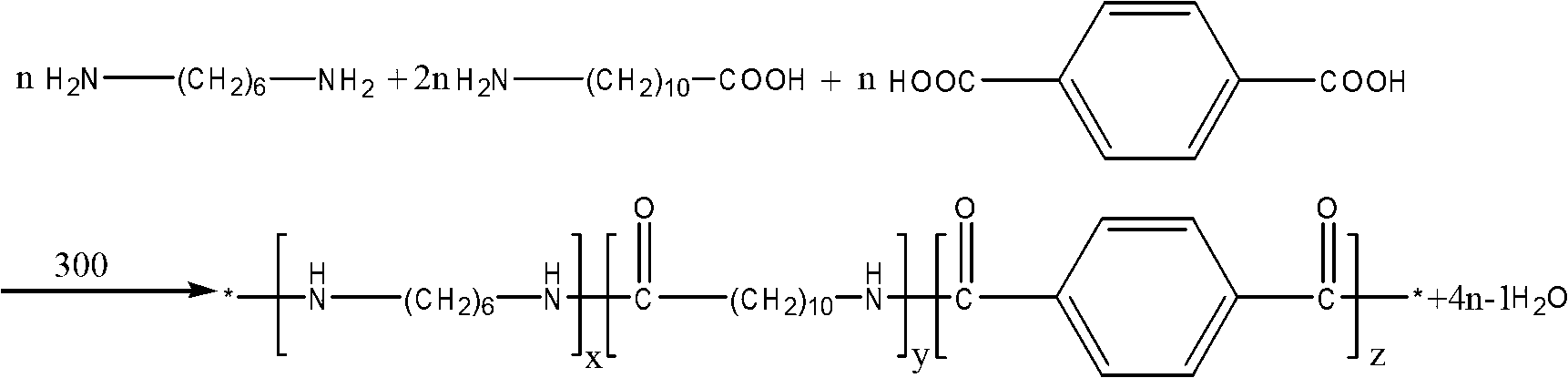

Embodiment 2

[0043]Add hexamethylenediamine, 11-aminoundecanoic acid, and terephthalic acid in the weight of 23.2kg, 80.4kg, and 33.2kg (molar ratio: 1:2:1) into the stirring polymerization reactor after vacuum drying, After evacuating for 10 minutes, pass nitrogen gas for 2 minutes, and circulate like this 6 times, so that the reactant exists in the environment under the protection of nitrogen gas, and the system pressure in the reactor is controlled to be 0.2 MPa. Seal the reactor and heat it to 130°C, and adjust the stirring speed of the polymerization reactor to 200r / min, control the system pressure in the reactor to 1.1MPa, keep the reactants warm and pressurized for 1 hour, and slowly release the gas to normal pressure, Reheat to 300° C., and adjust the stirring speed of the polymerization reactor to 50 r / min. After constant temperature, continue vacuuming for 8 hours, and the reaction ends. Nitrogen-filled material is discharged, cooled in a water tank, and pelletized to prepare PA1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com