Patents

Literature

36results about How to "Aggregation condition reached" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Long carbon-chain semi-aromatic polyamide and synthetic method of same

ActiveCN102796257ASimple preparation processThe polymerization process is controllablePolyamideCarbon chain

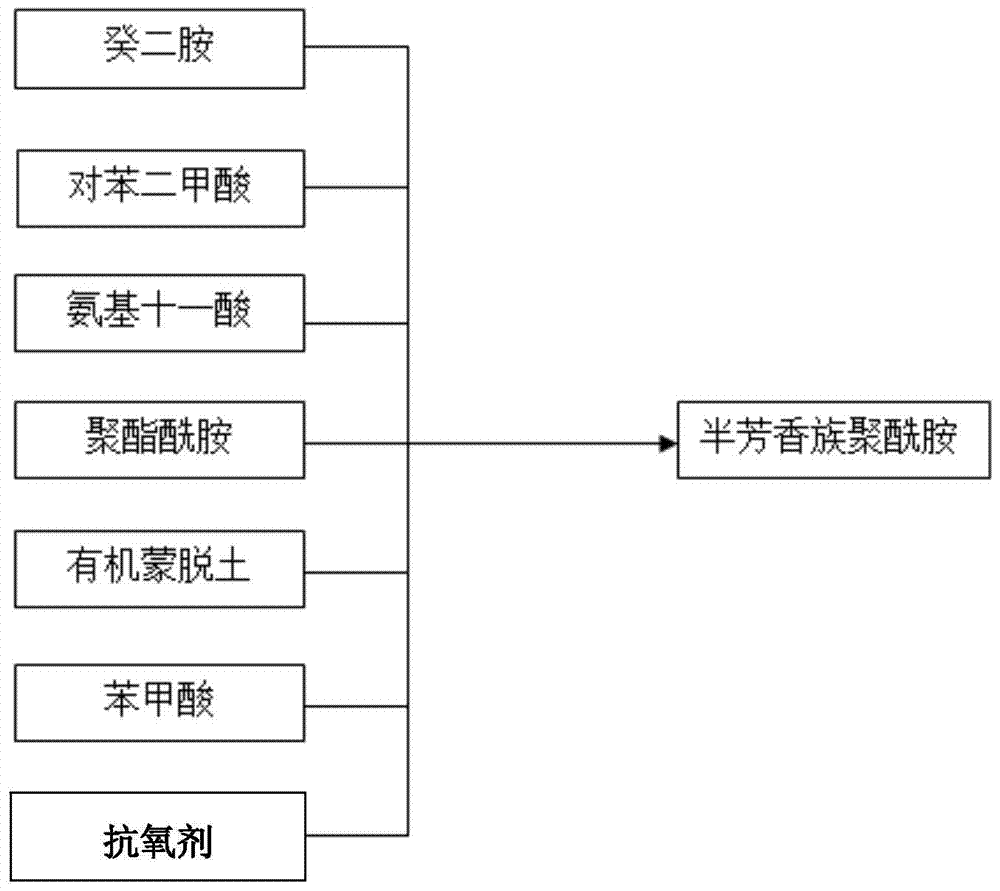

The invention discloses a long carbon-chain semi-aromatic polyamide and preparation method of the same. The long carbon-chain semi-aromatic polyamide has good heat resistance, rigidity at high temperature, chemical resistance and size stability, and low water absorption. The synthetic method of the invention comprises: first, adding dried diamine monomer, 11-aminoundecanoic acid, and terephthalic acid into a stirred polymerization reactor according to a certain mol ratio, after vacuum-pumping, feeding in inert gas, heating the reactor hermetically to 120-170 DEG C, and maintaining the temperature and the condition of self pressure for the reactants for 0.5-24 hours before venting to normal pressure; and then reheating to 300-350 DEG C, and keeping vacuum-pumping after reaching the constant temperature. The polyamide of the invention is simple in preparation technology, controllable in polymerization process, and can replace steels by being applied to the fields such as automobiles, machinery, and electronic and electrical equipment.

Owner:SINOPLAST NEW MATERIAL

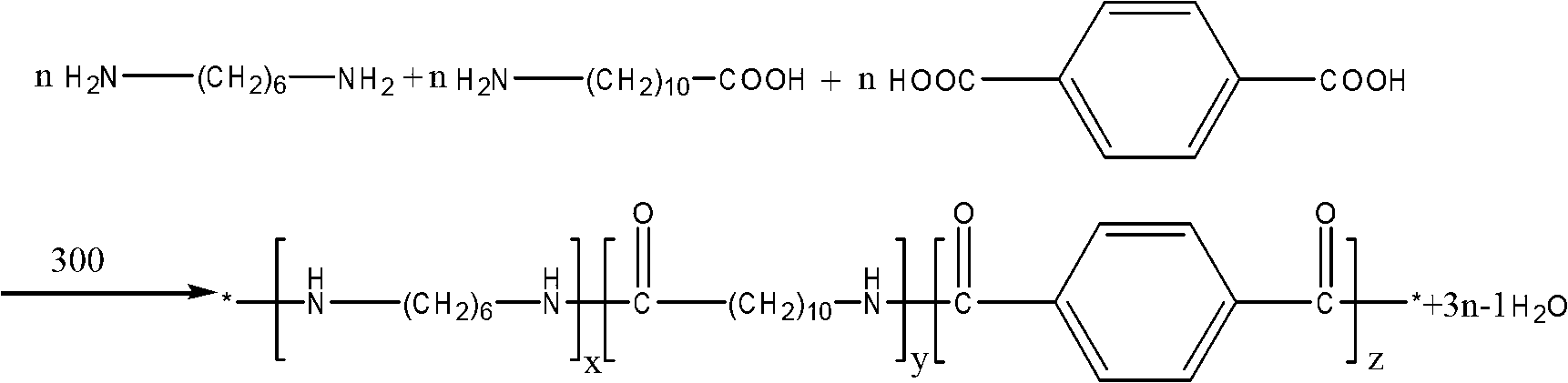

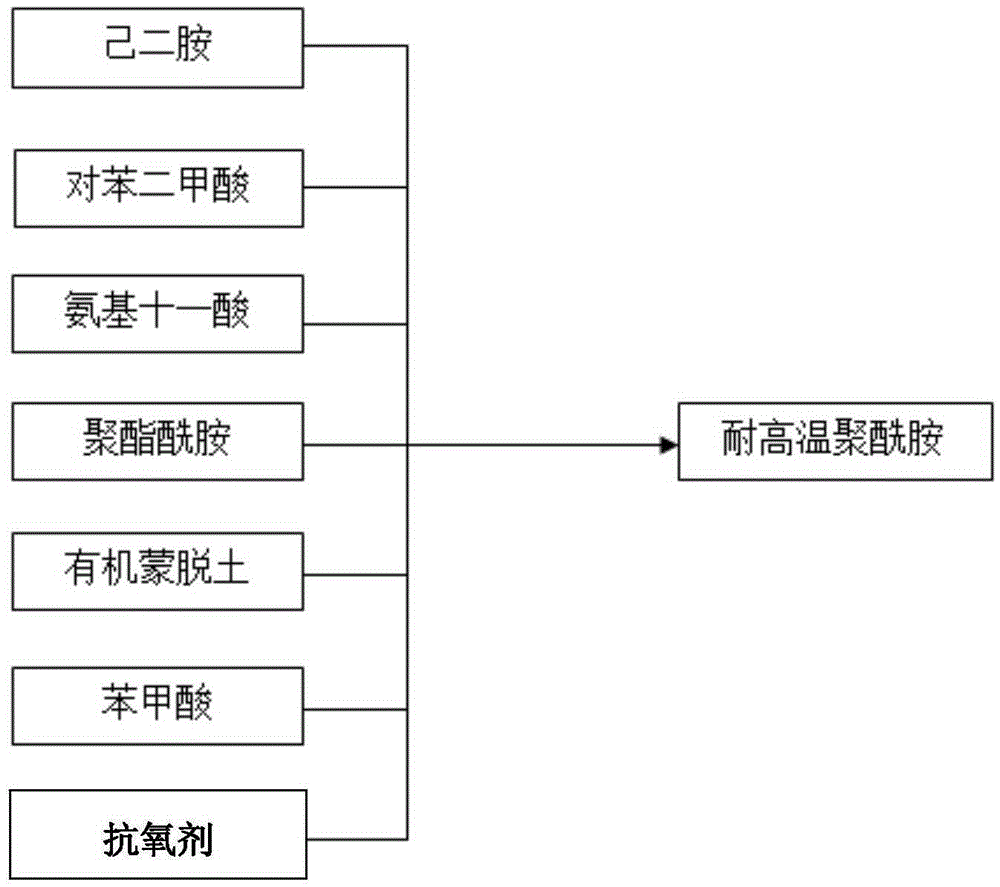

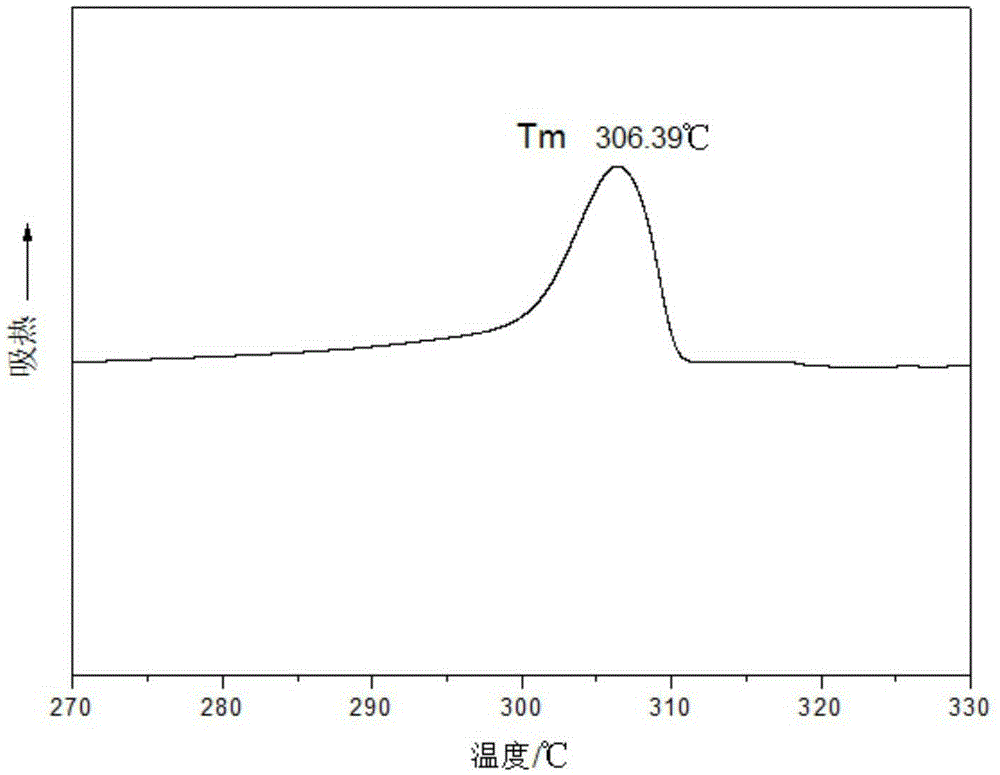

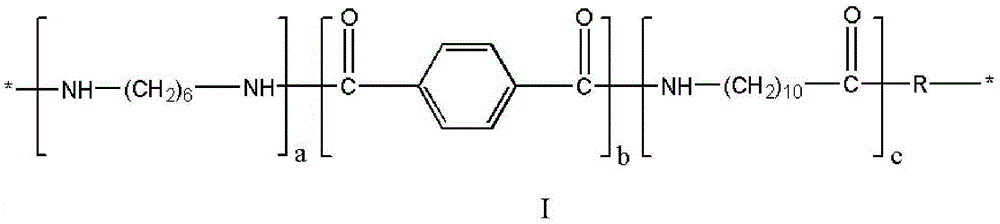

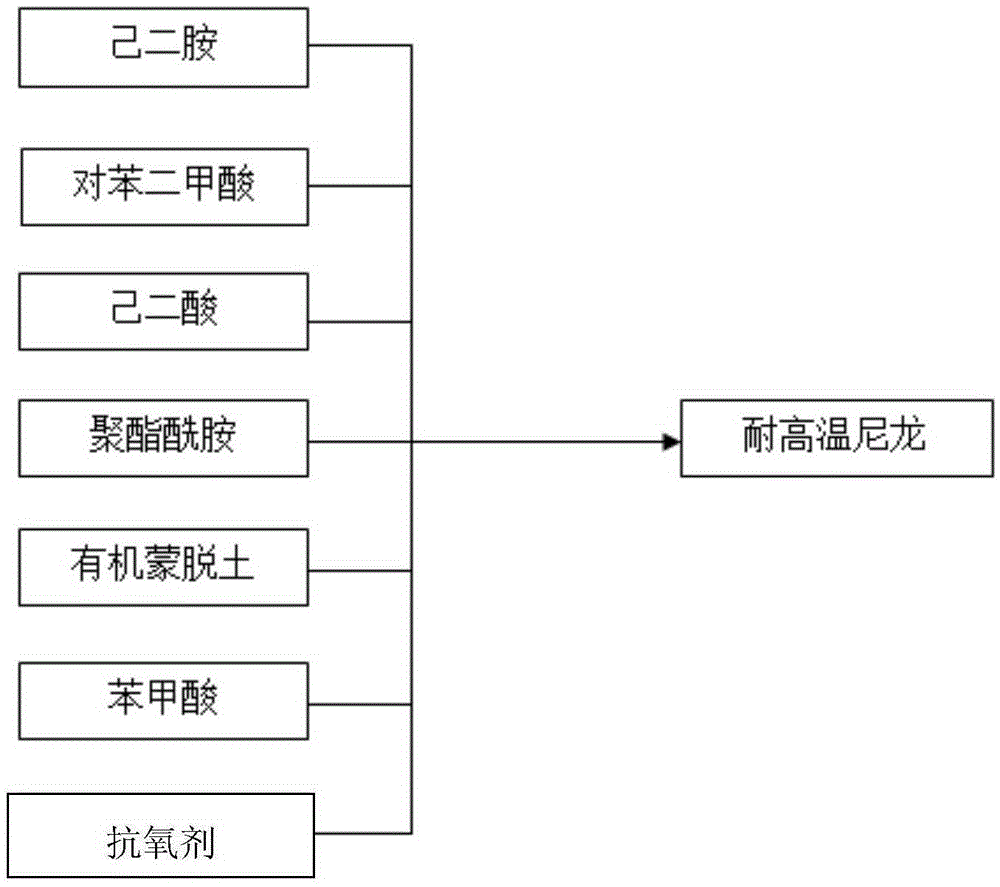

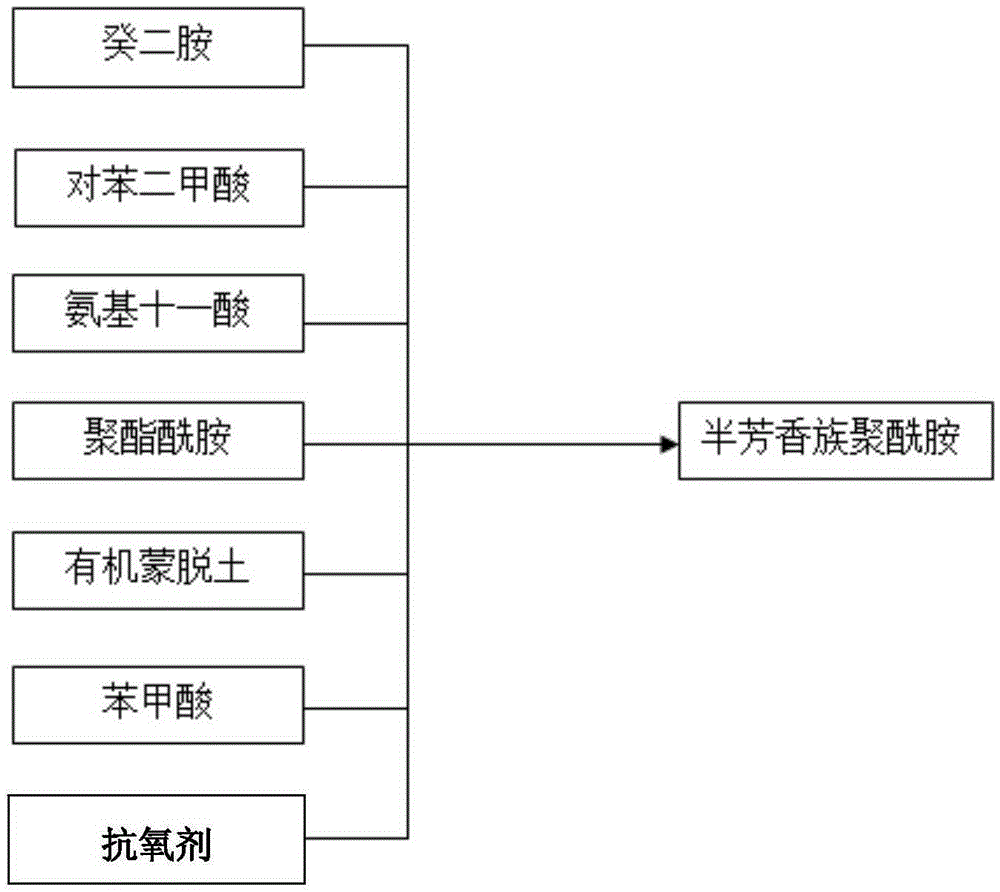

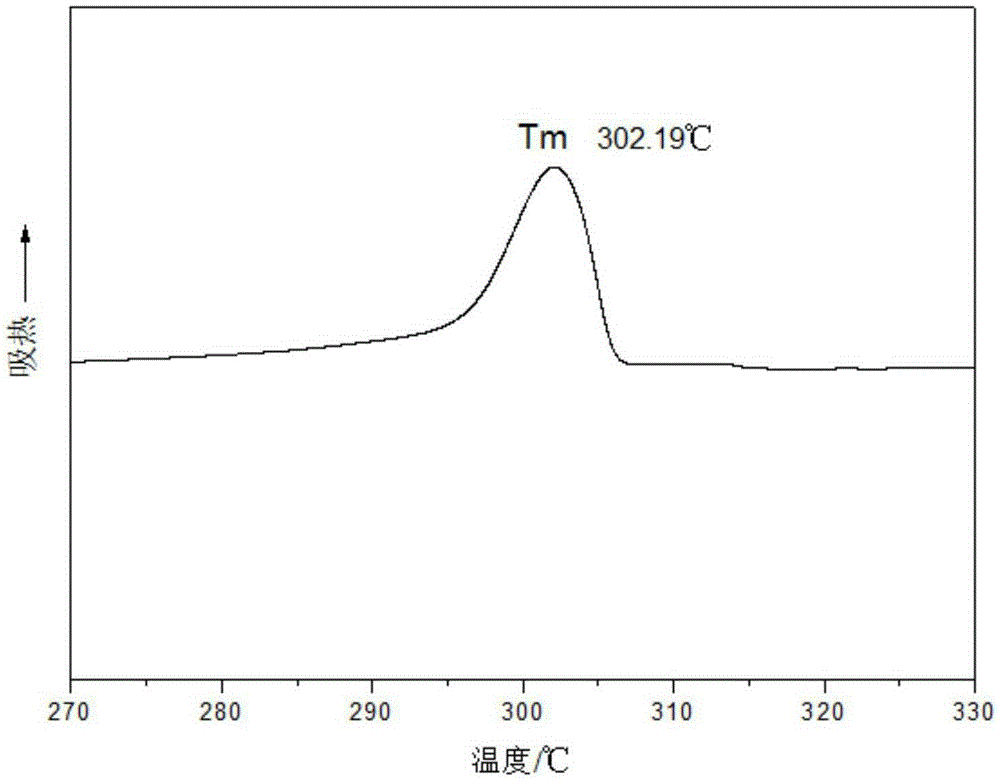

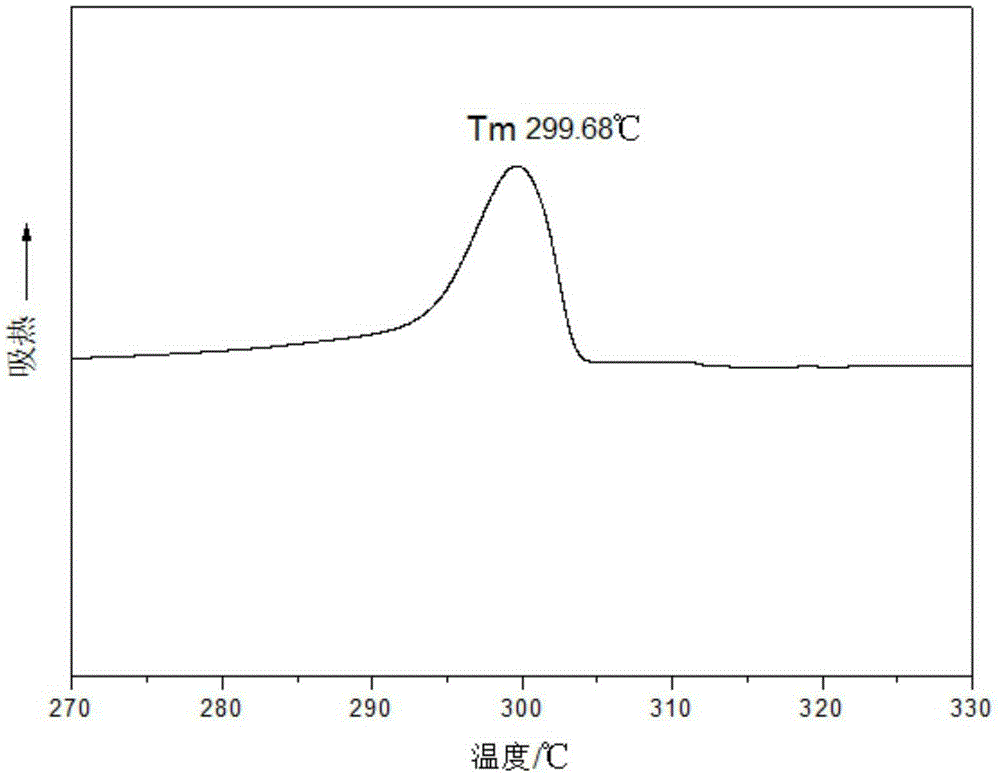

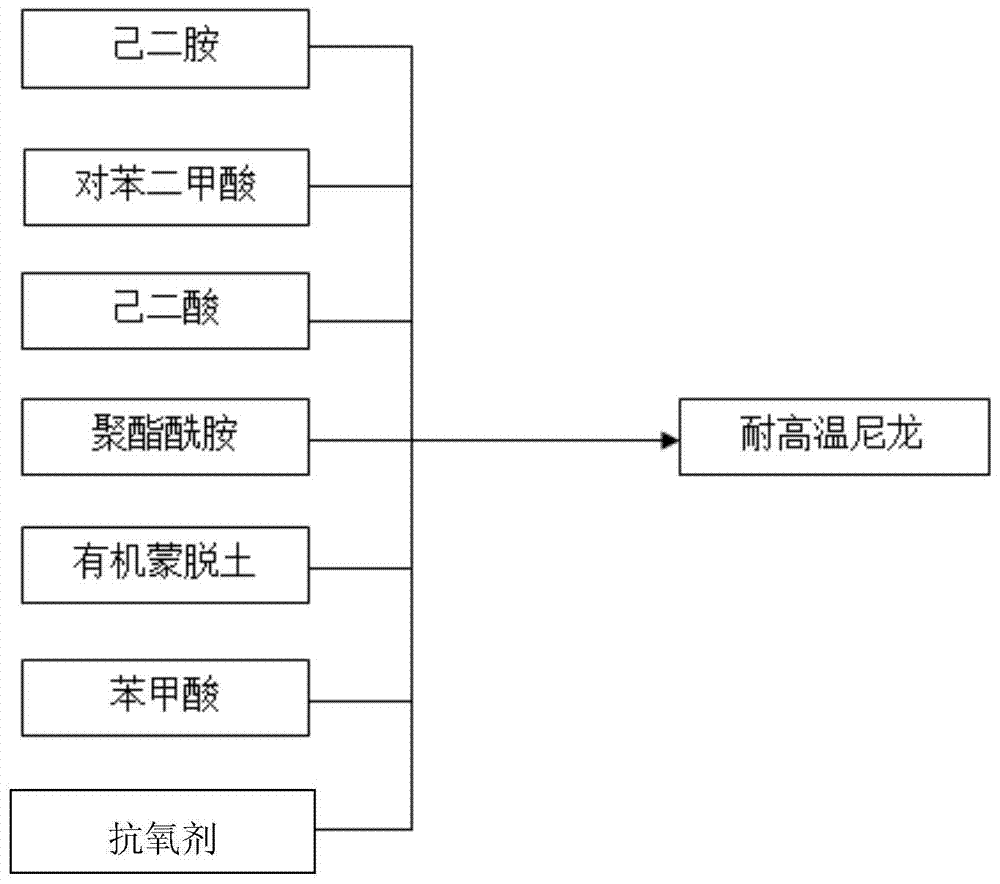

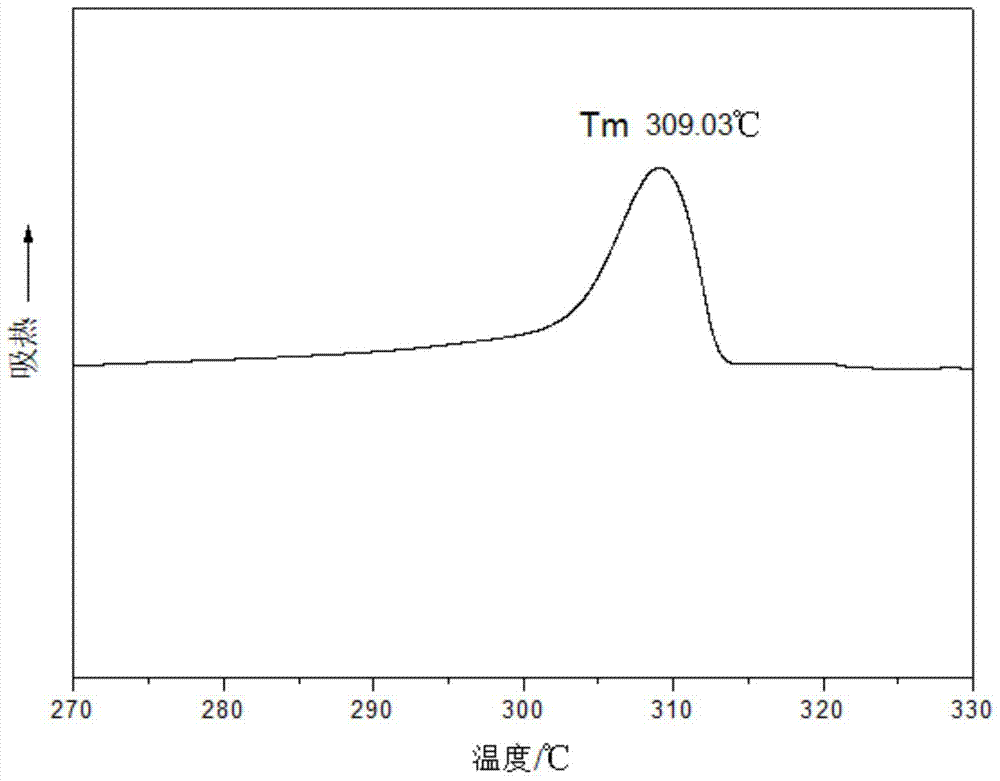

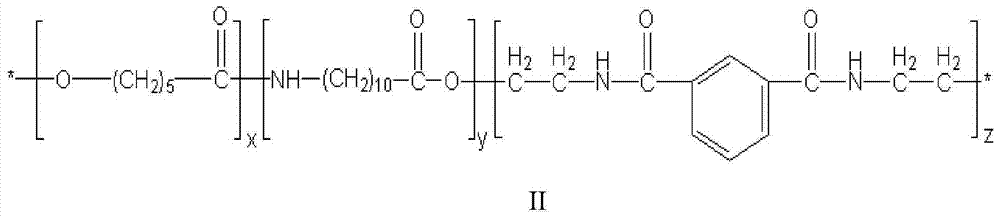

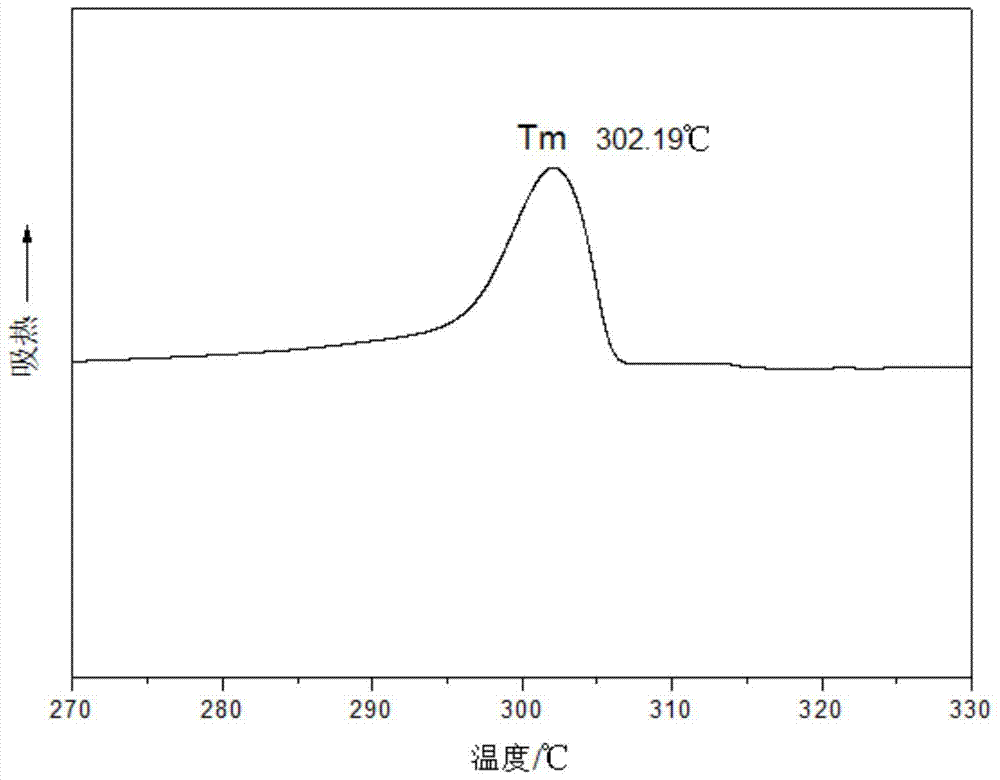

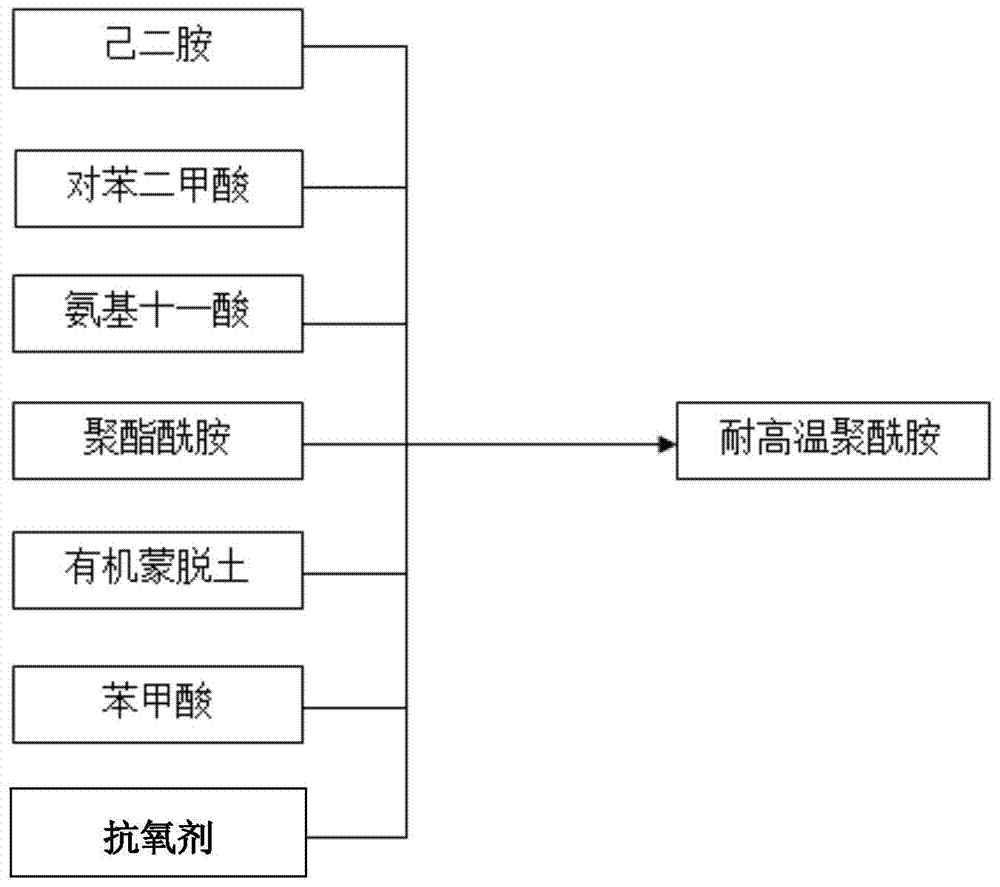

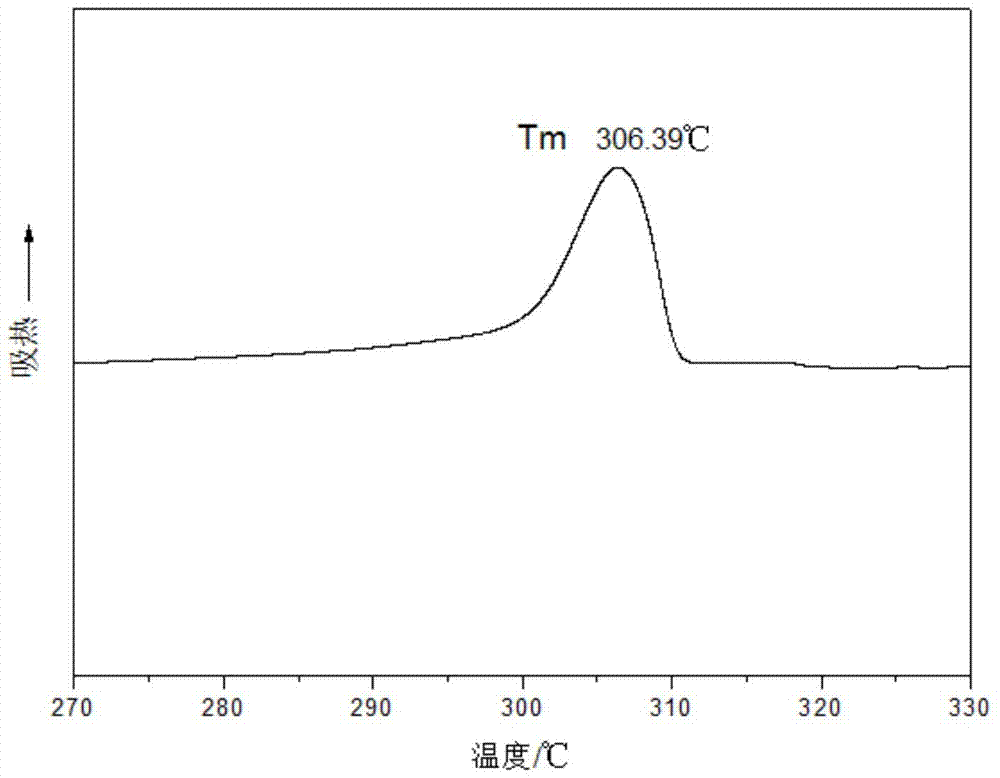

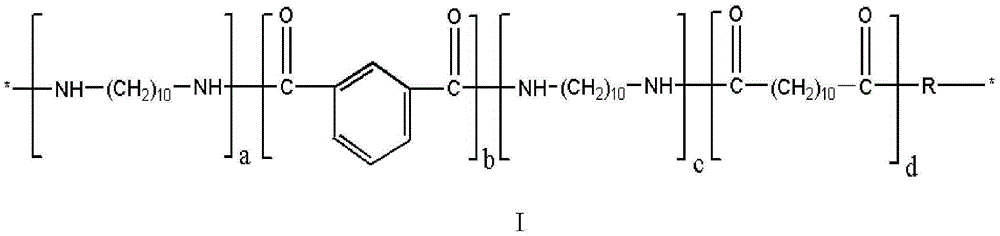

High temperature resistant polyamide and synthesis method thereof

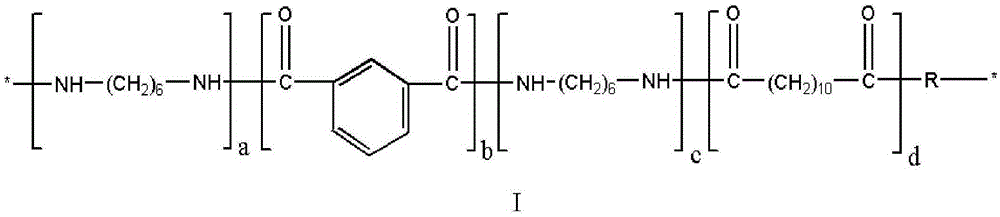

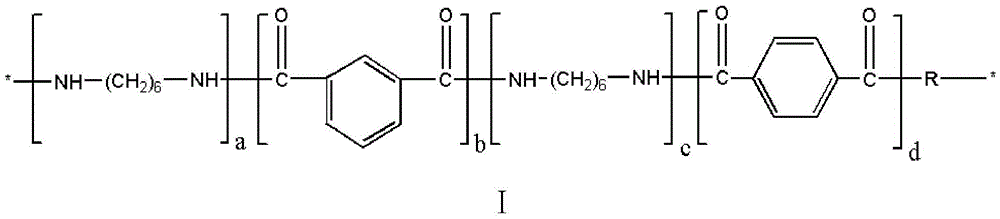

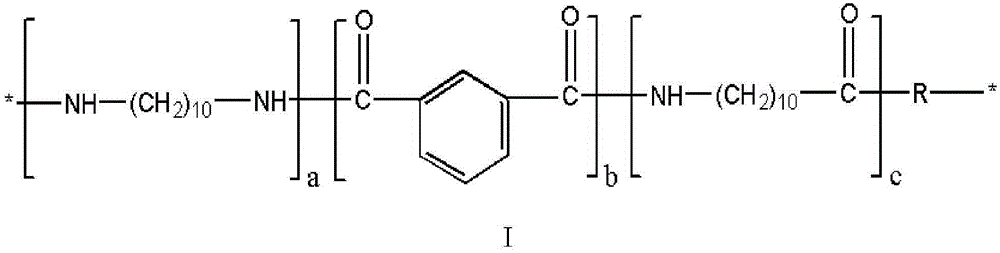

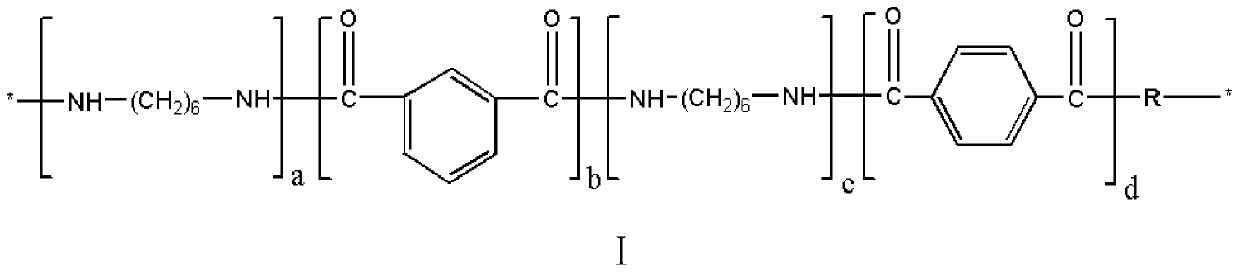

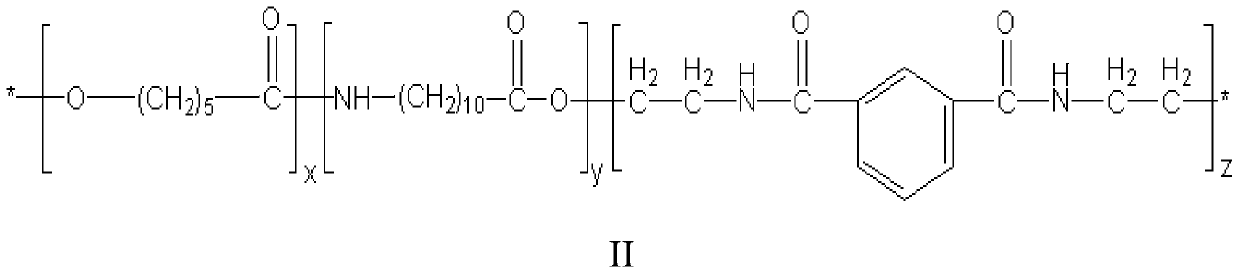

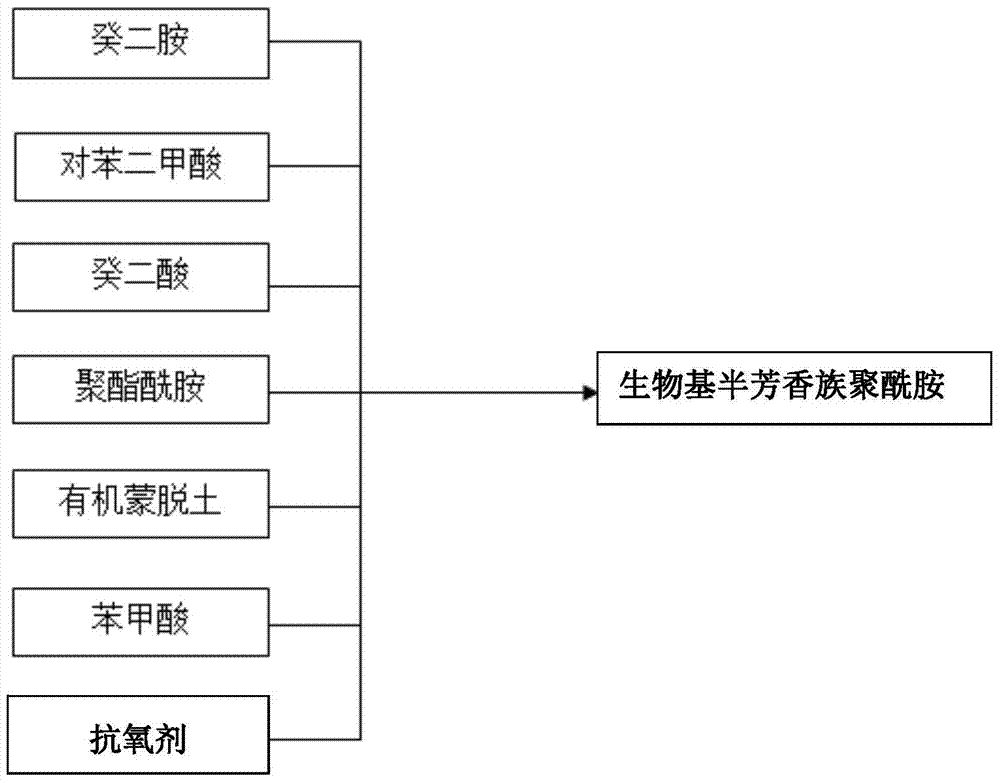

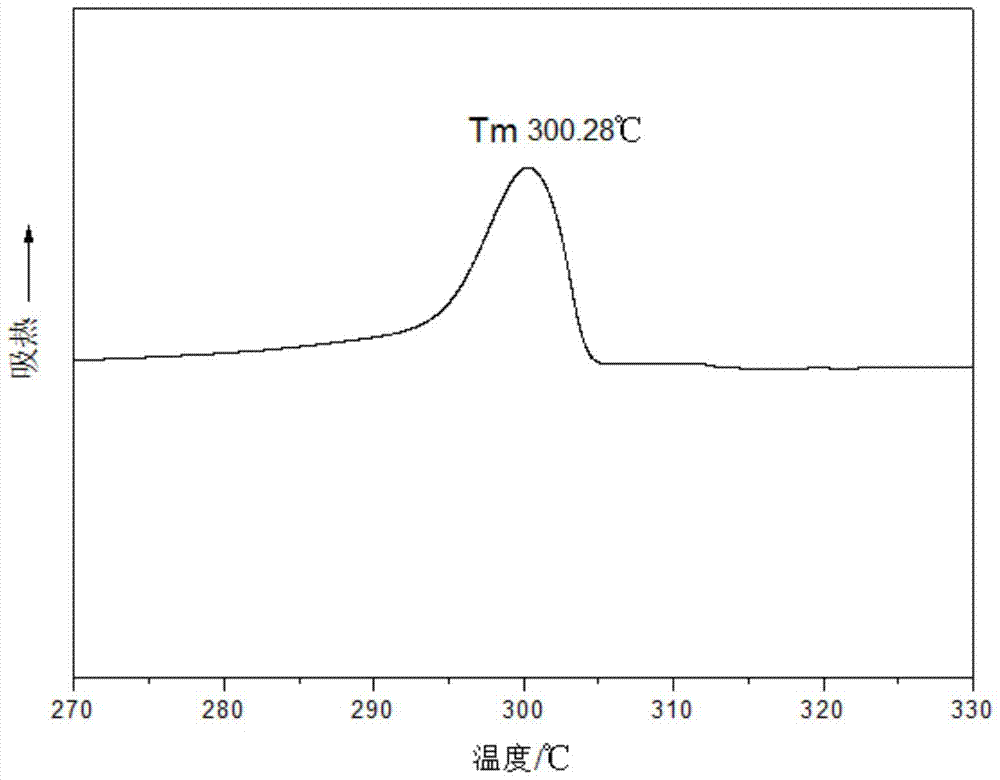

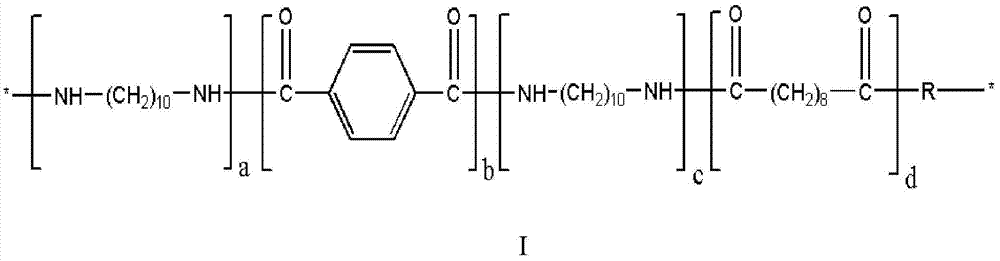

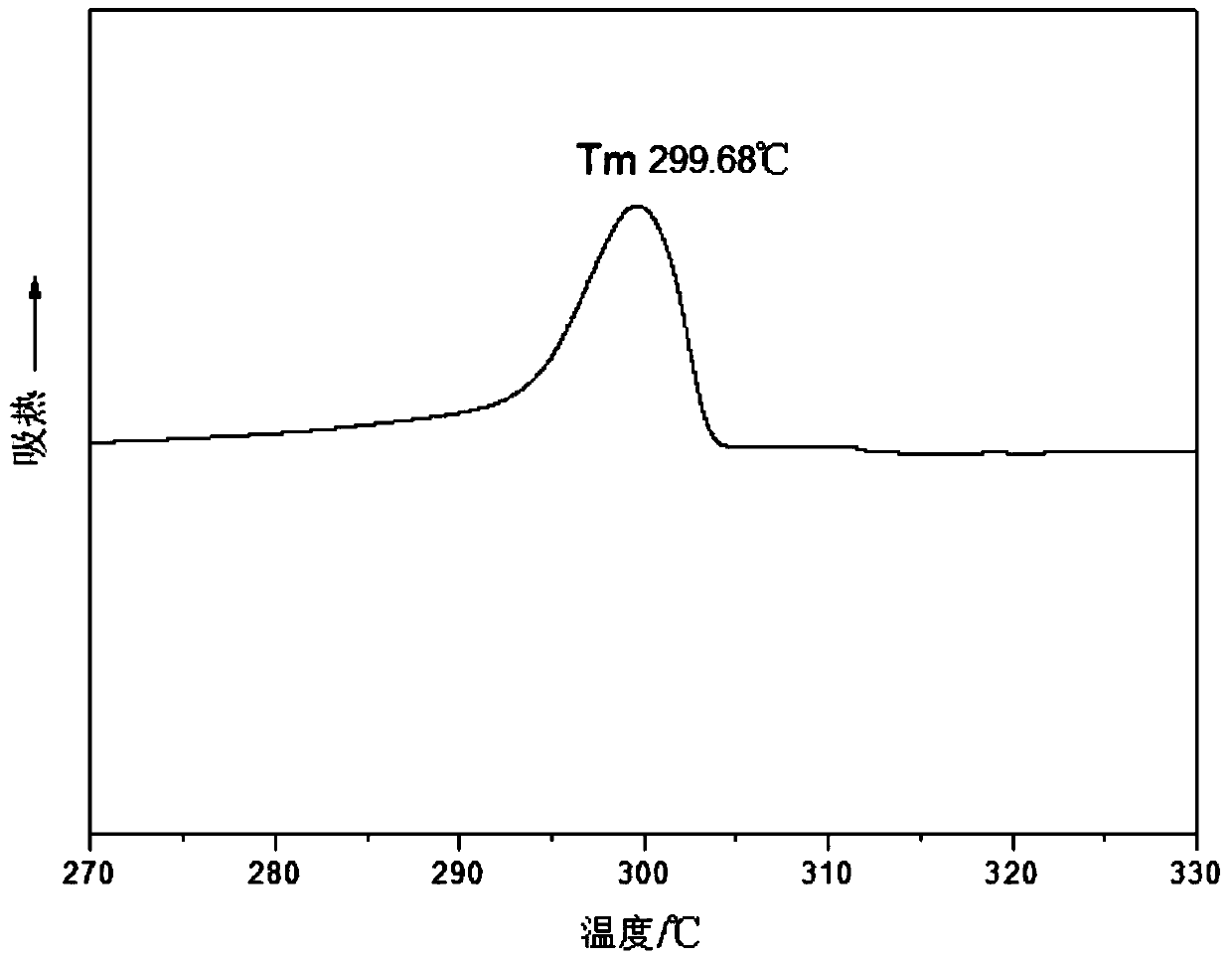

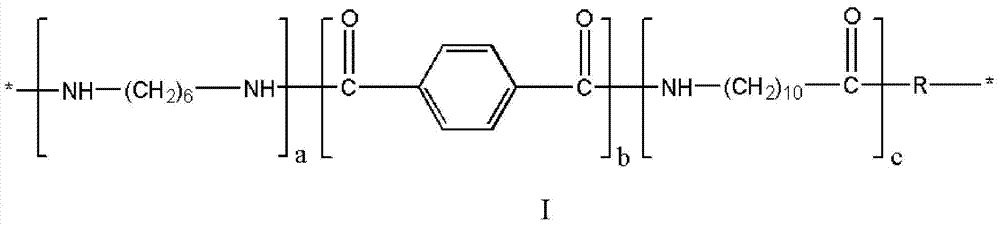

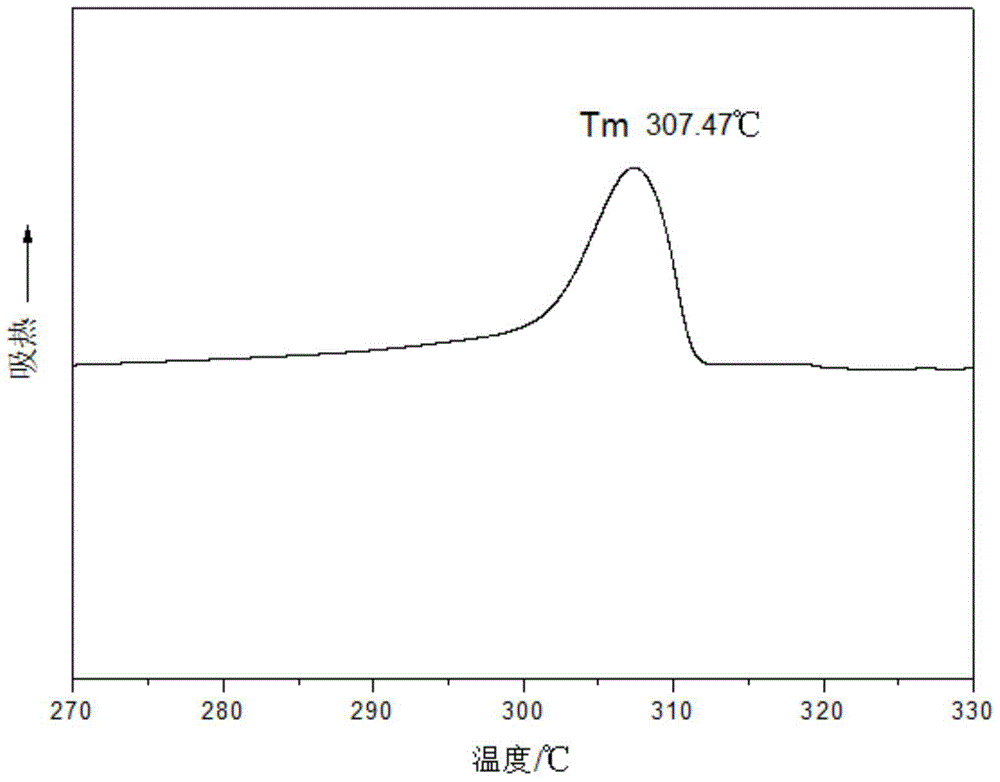

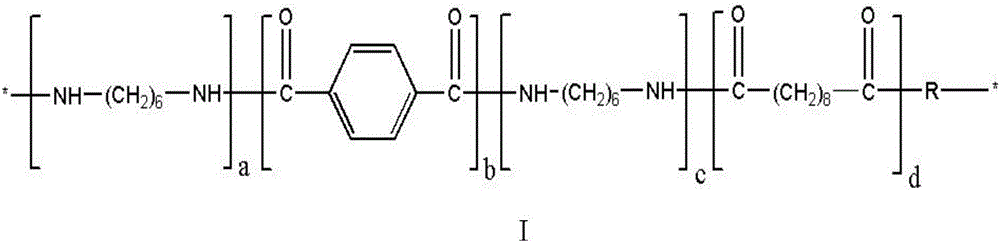

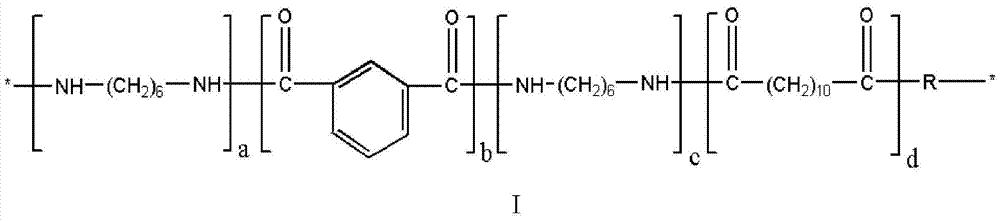

The invention relates to high temperature resistant polyamide and a synthesis method thereof. The high temperature resistant polyamide has the structure as shown in the specification, wherein a=10-200, b=10-200, c=10-200, and R is polyester amide. The high temperature resistant polyamide has better mechanical properties and heat resistance, low water absorption and excellent processability and has the characteristic of biogenetic derivation, so that the high temperature resistant polyamide can be applied to the fields of electronic appliances, LEDs, vehicles, aerospace, war industry and the like.

Owner:ZHONGBEI UNIV

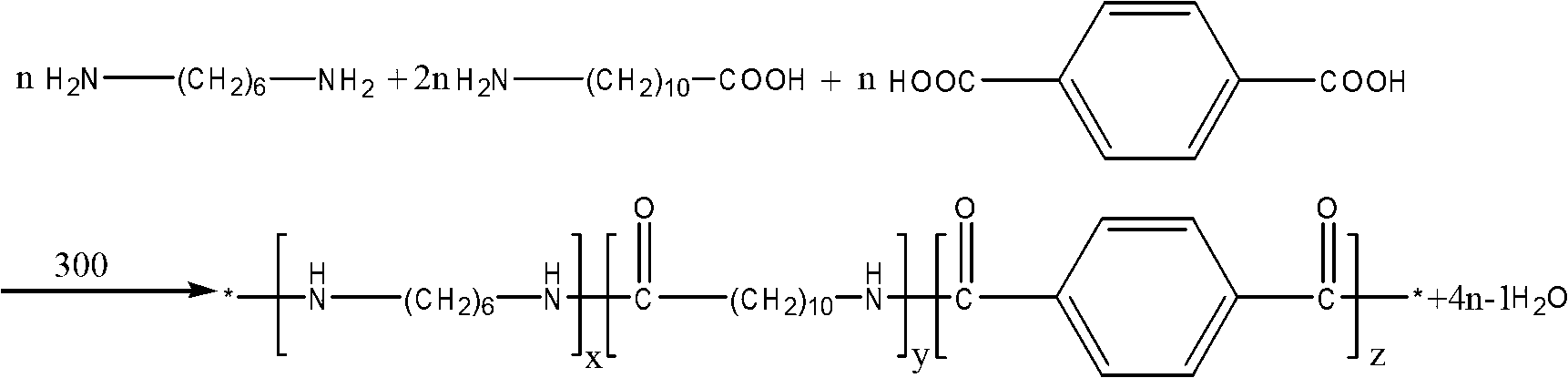

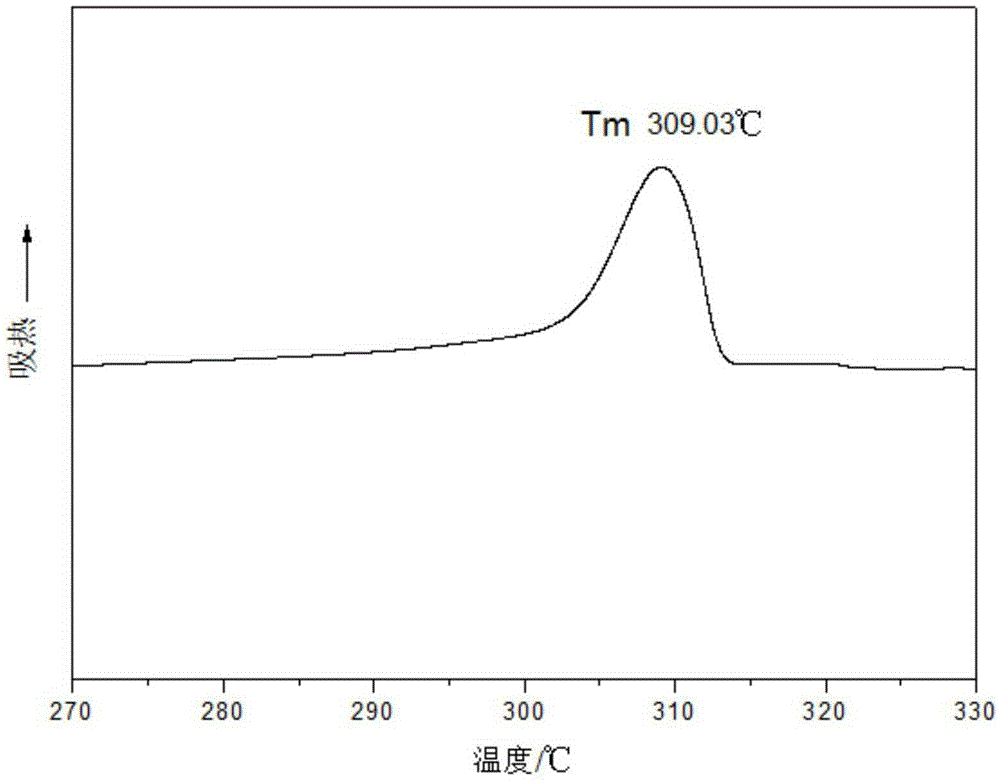

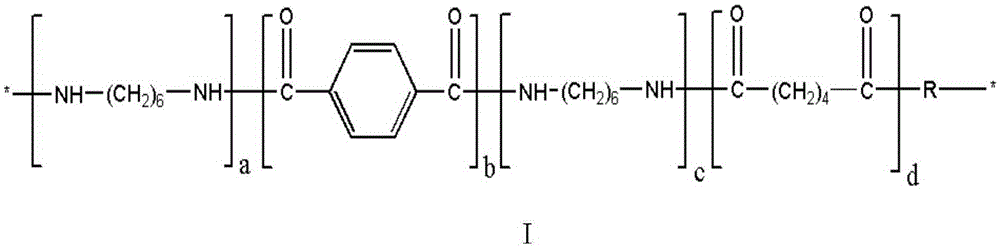

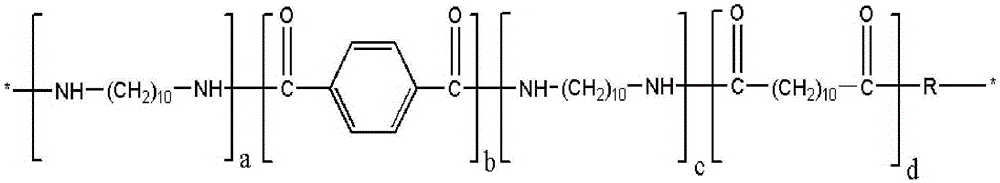

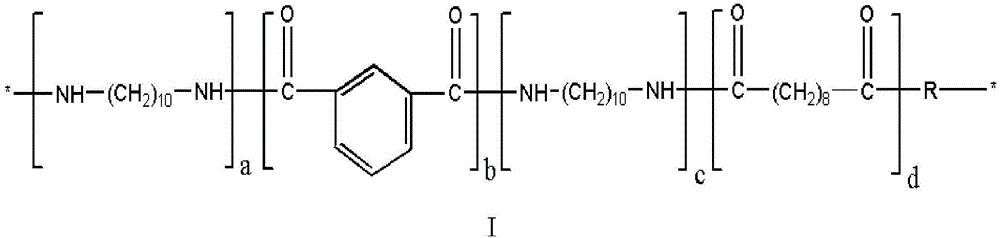

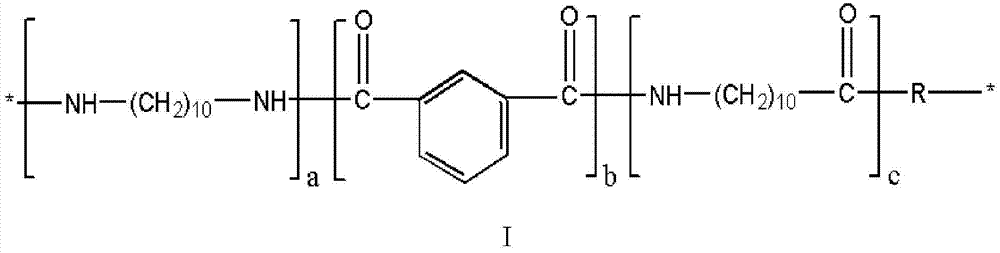

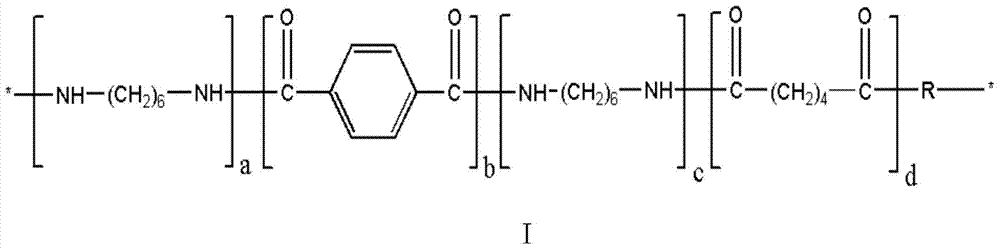

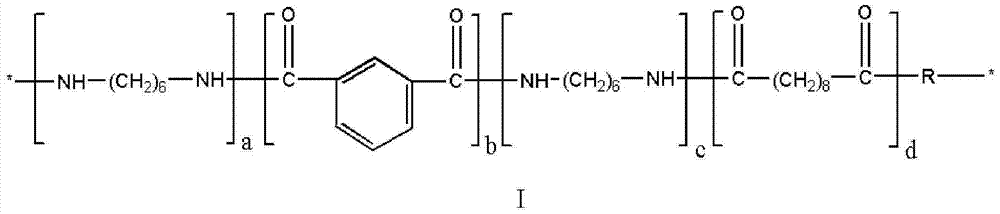

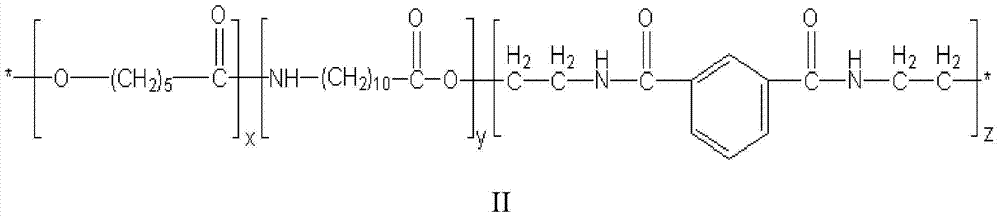

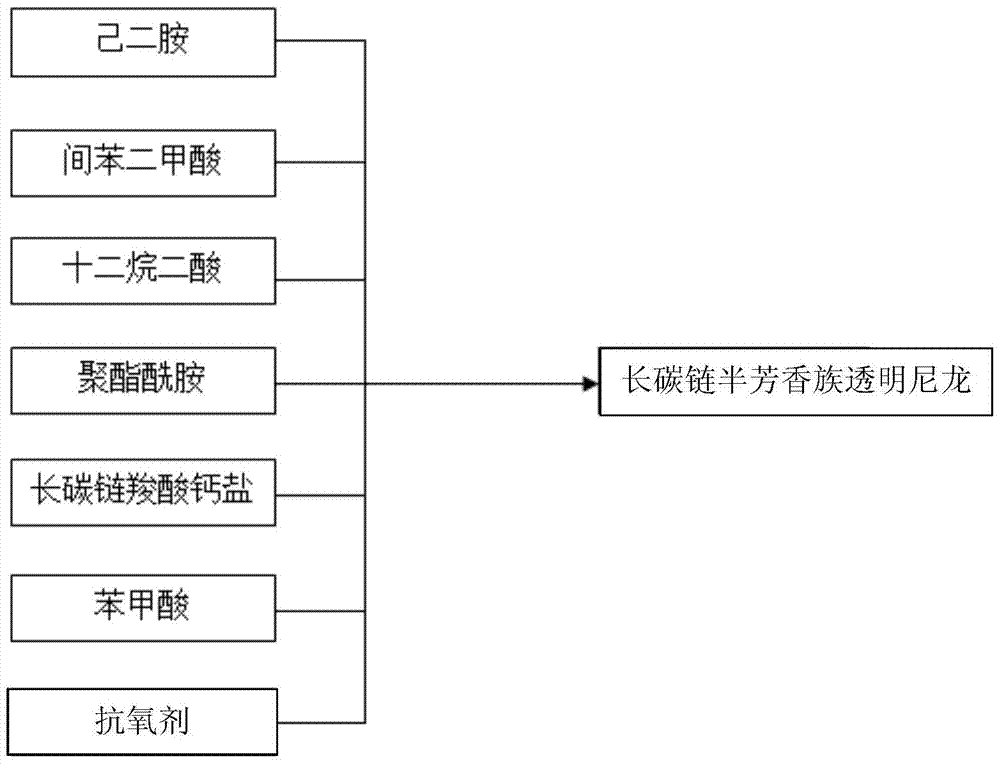

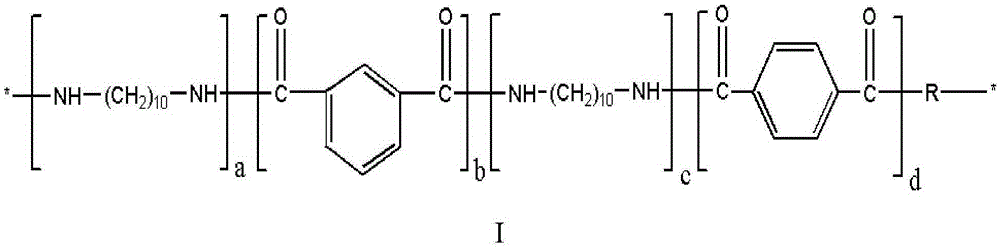

High-temperature resistant nylon and synthesis method thereof

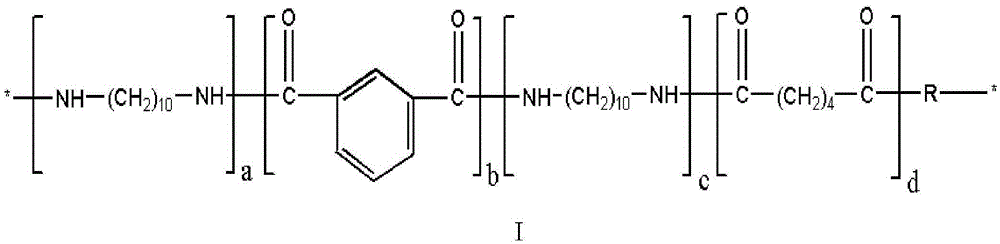

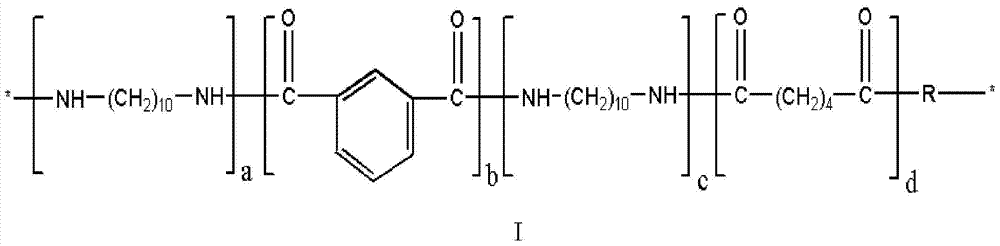

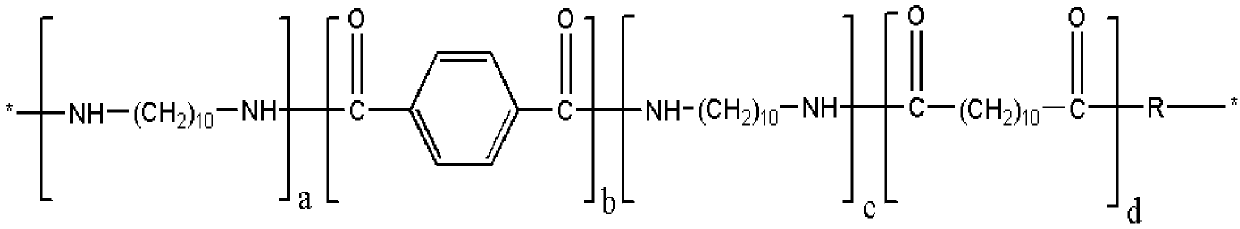

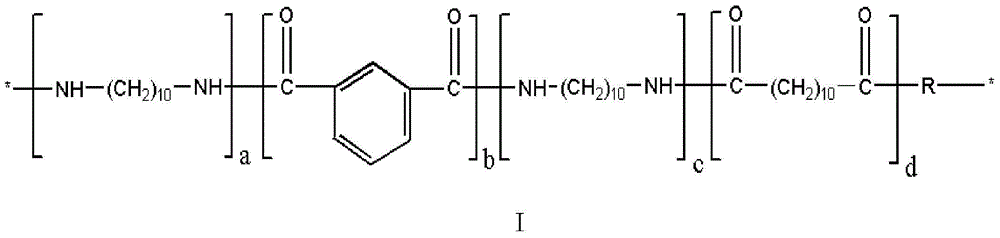

The invention discloses a high-temperature resistant nylon and a synthesis method thereof. The high-temperature resistant nylon comprises a structure shown in the formula I, wherein a=10 to 100, b=10 to 200, c=10 to 100, d=10 to 100, and R is polyester-amide. The high-temperature resistant nylon is relatively high in mechanical property and heat resistance, low in hygroscopic coefficient, and excellent in processability, and can be applied to the fields such as electronic apparatus, LEDs, automobiles, aerospace and military industry.

Owner:ZHONGBEI UNIV

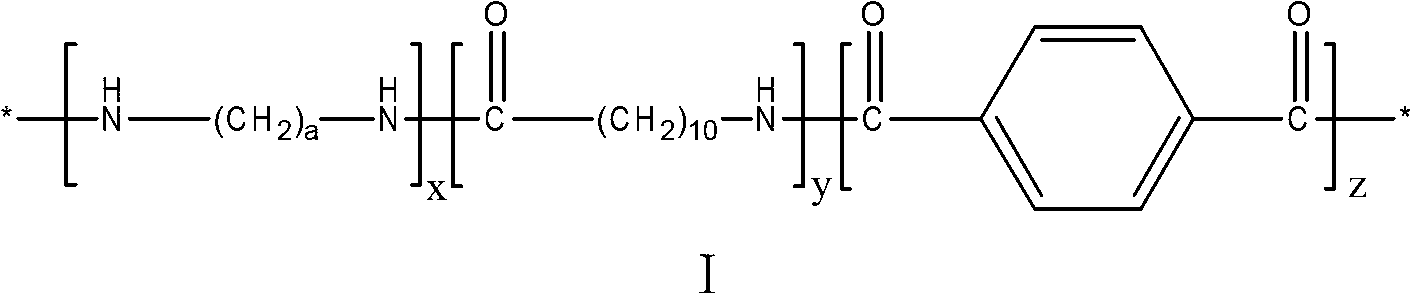

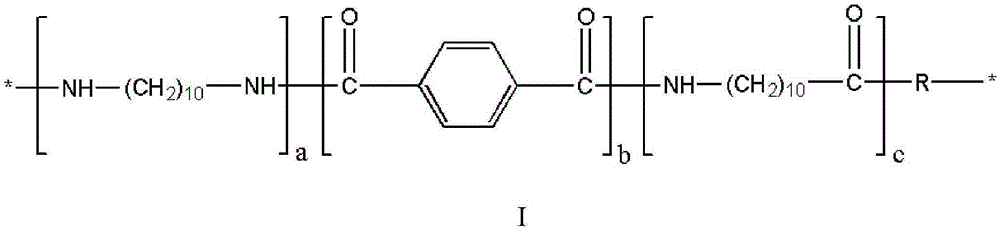

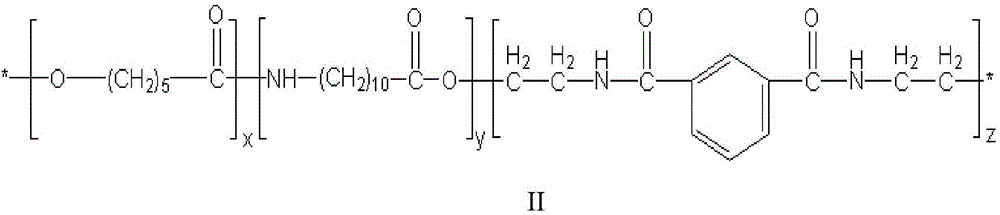

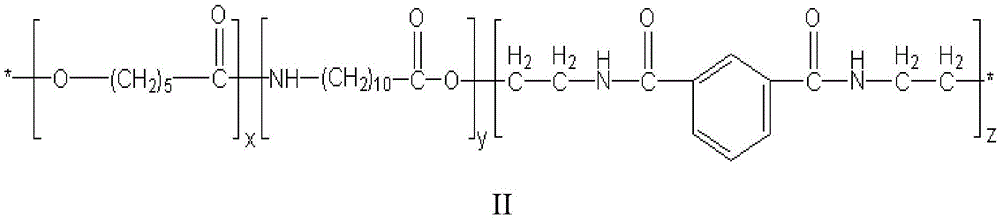

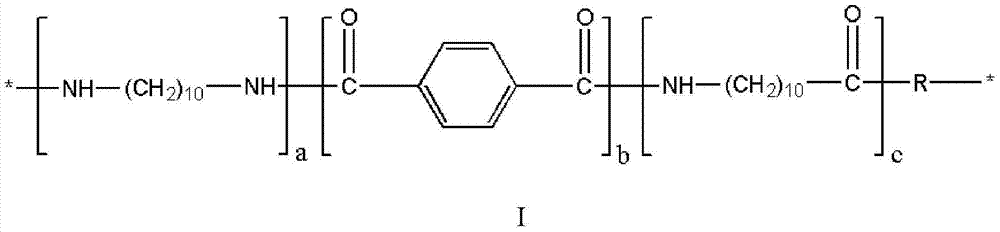

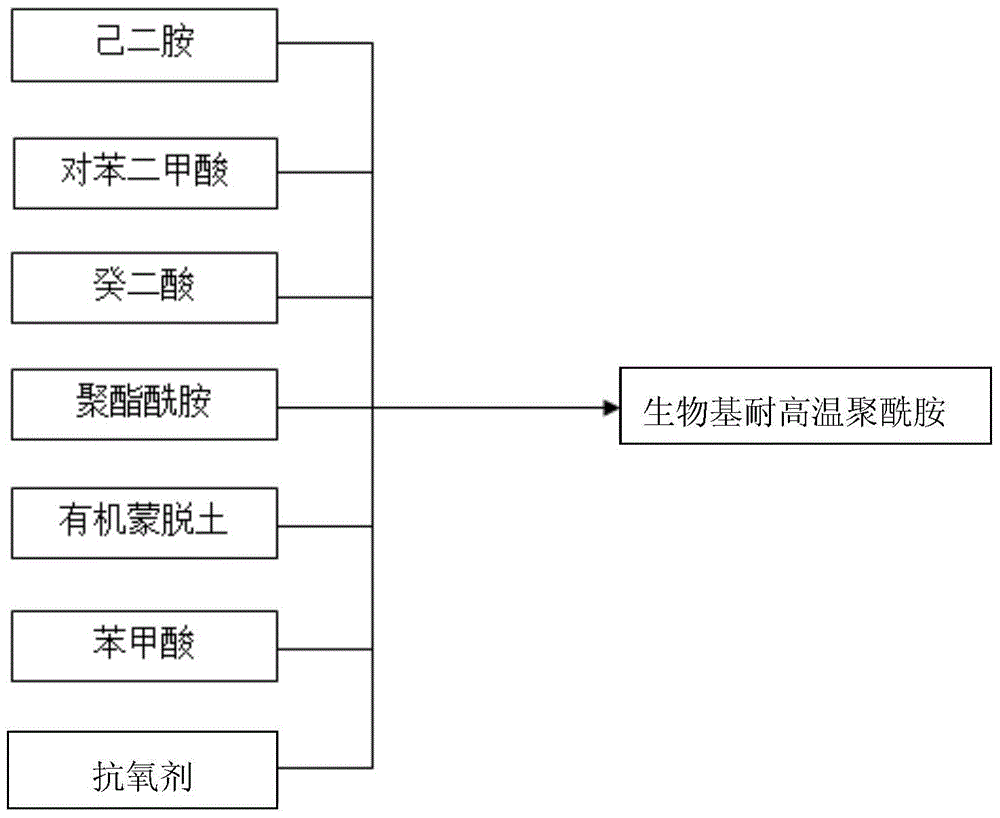

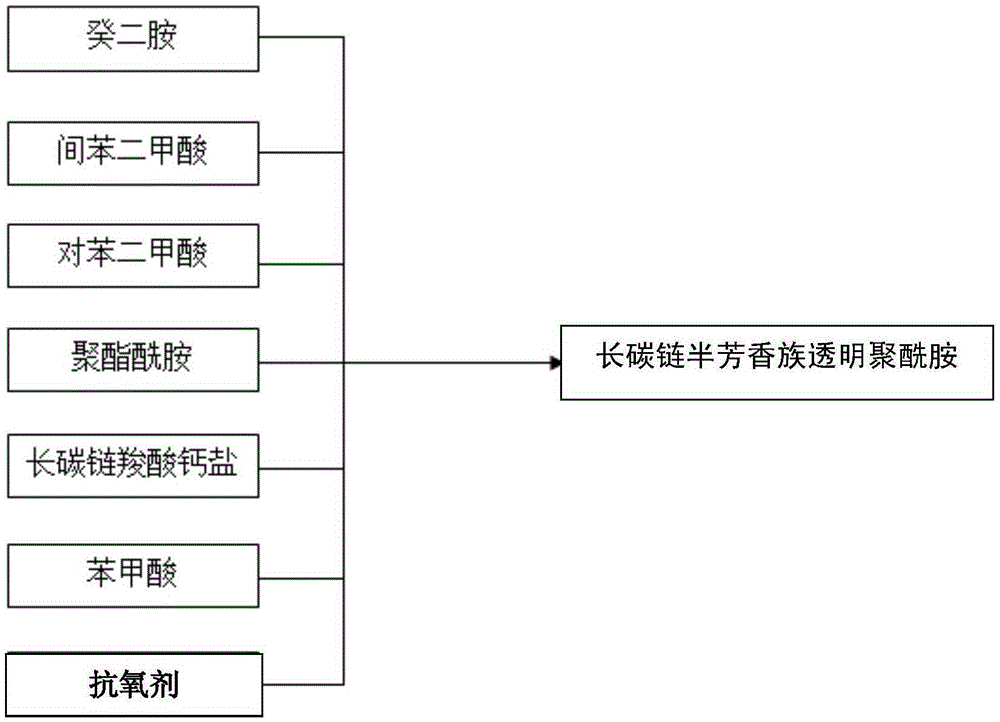

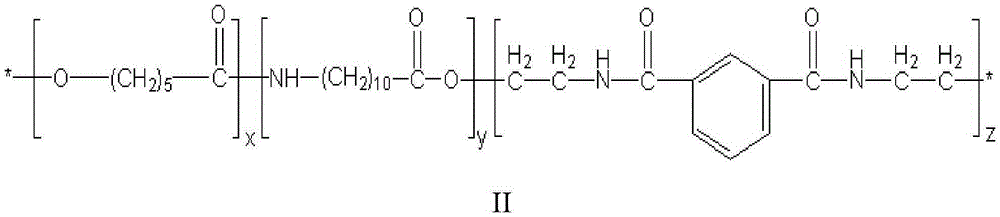

Semi-aromatic polyamide and synthesis method thereof

ActiveCN105348520AImprove mechanical properties and heat resistanceLow water absorptionPolyamideSynthesis methods

The invention relates to semi-aromatic polyamide and a synthesis method thereof. The semi-aromatic polyamide has the structure shown in the formula I (shown in the description); in the formula I, a is equal to 10-200, b is equal to 10-200, c is equal to 10-100 and R is polyesteramide. The semi-aromatic polyamide has a relatively high mechanical property, relatively high heat resistance, low water absorption, excellent processability and biologically-derived characteristics, and can be applied to the fields of electronics and electrical appliances, LEDs, automobiles, aerospace, military and the like.

Owner:ZHONGBEI UNIV

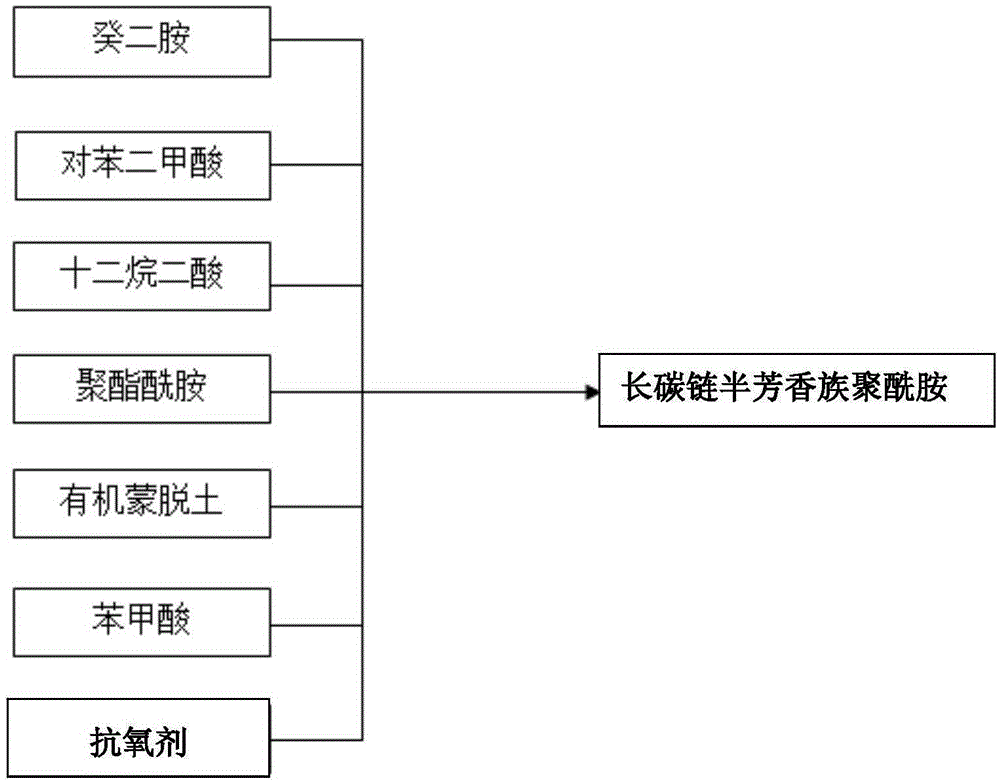

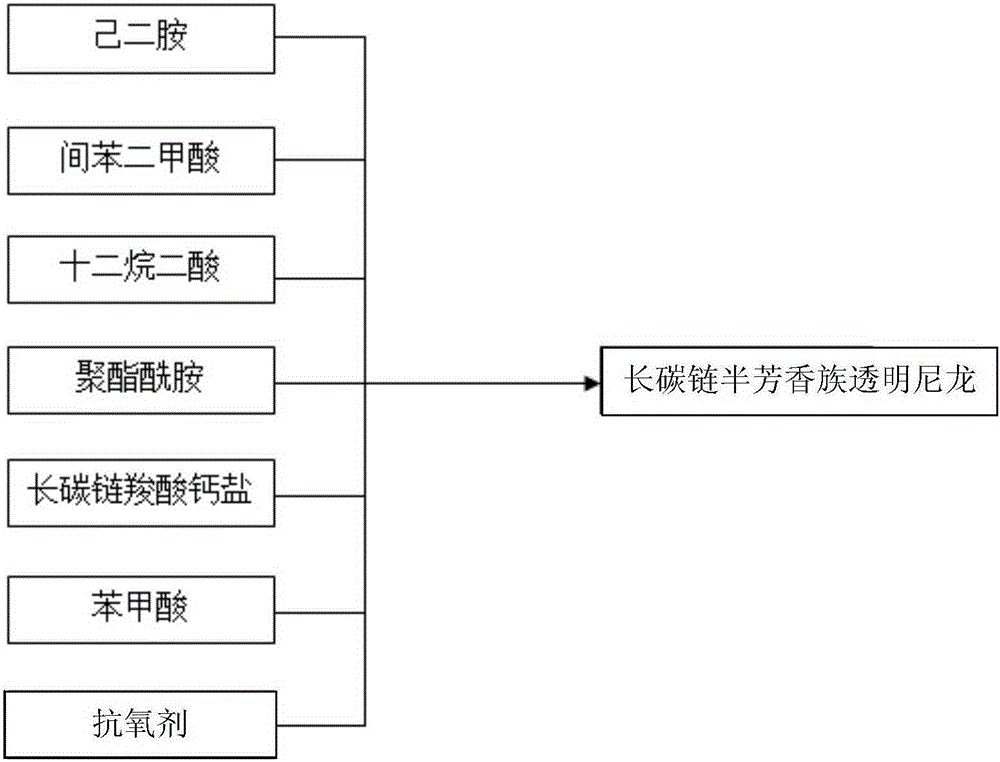

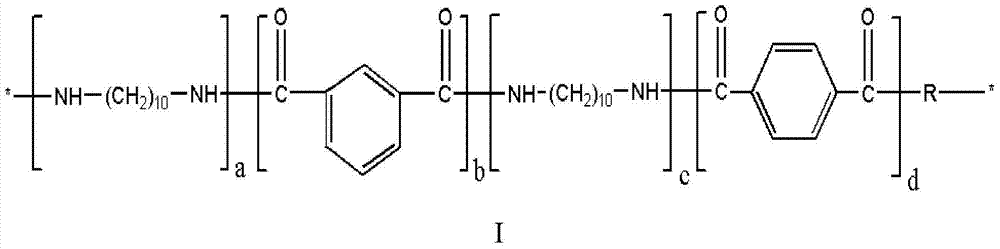

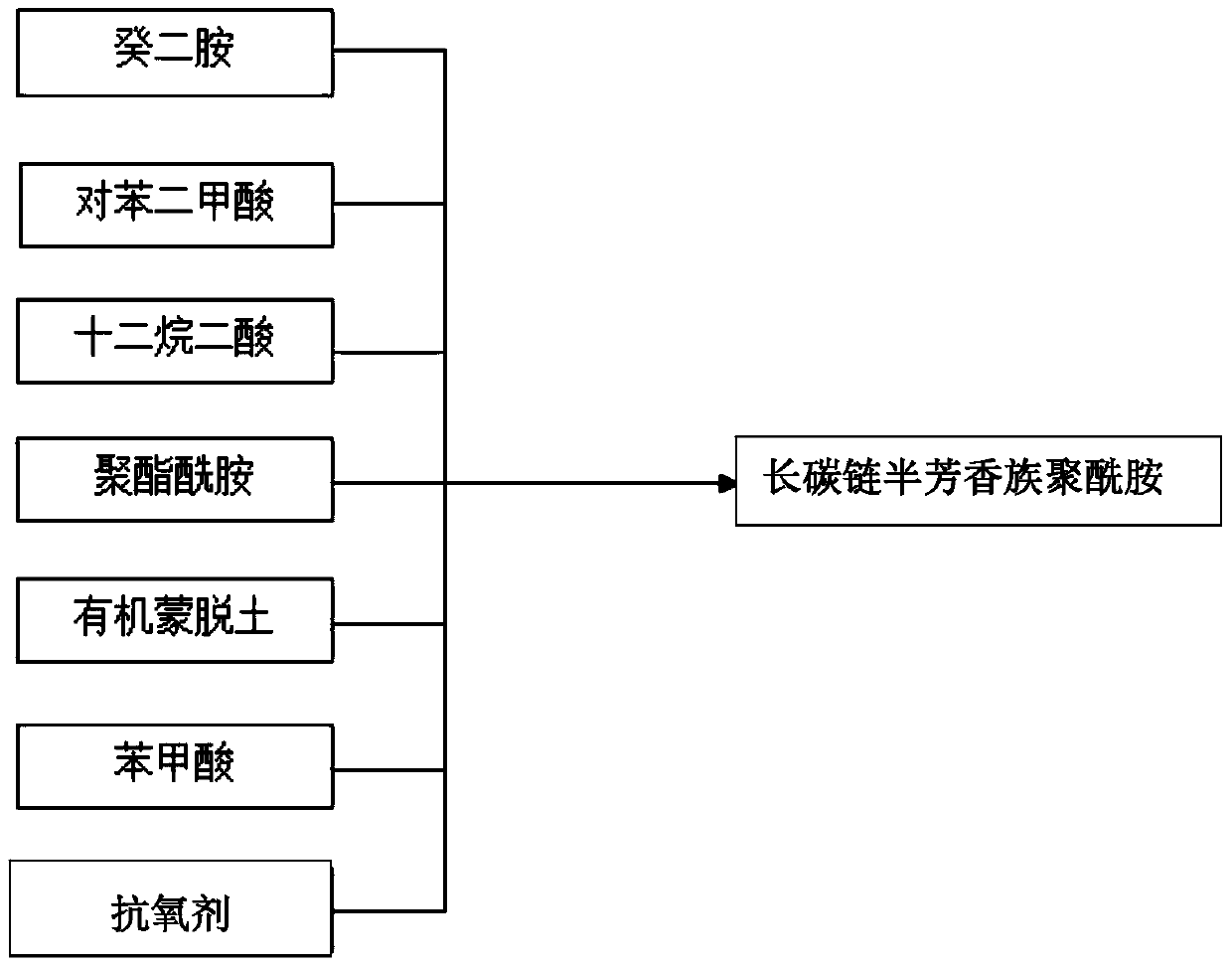

Long-carbon-chain semi-aromatic polyamide and synthetic method thereof

The invention relates to long-carbon-chain semi-aromatic polyamide and a synthetic method thereof. Long-carbon-chain semi-aromatic polyamide has a structure in a formula I (as shown in the specification), wherein a is equal to 10-100, b is equal to 10-200, c is equal to 10-100, d is equal to 10-100, and R represents polyesteramide. Long-carbon-chain semi-aromatic polyamide has the characteristics of relatively high mechanical property and heat resistance, low water absorption rate, excellent processing performance and biogenetic derivation and can be applied to the fields of electronics, LEDs, automobiles, aerospace, war industry and the like.

Owner:ZHONGBEI UNIV

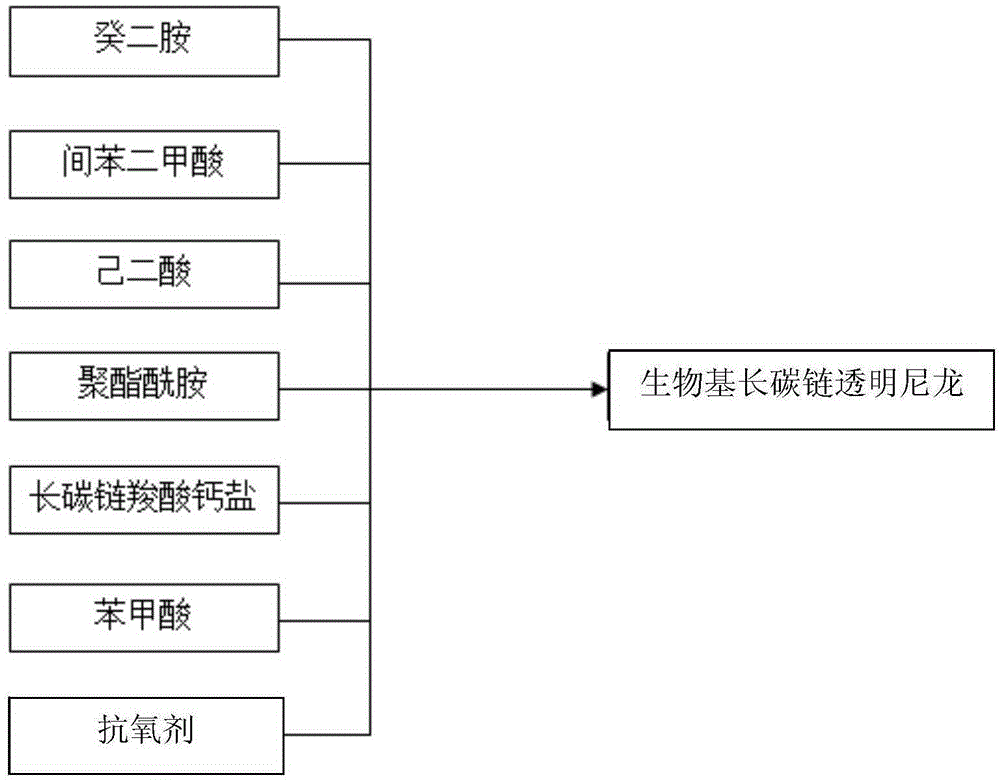

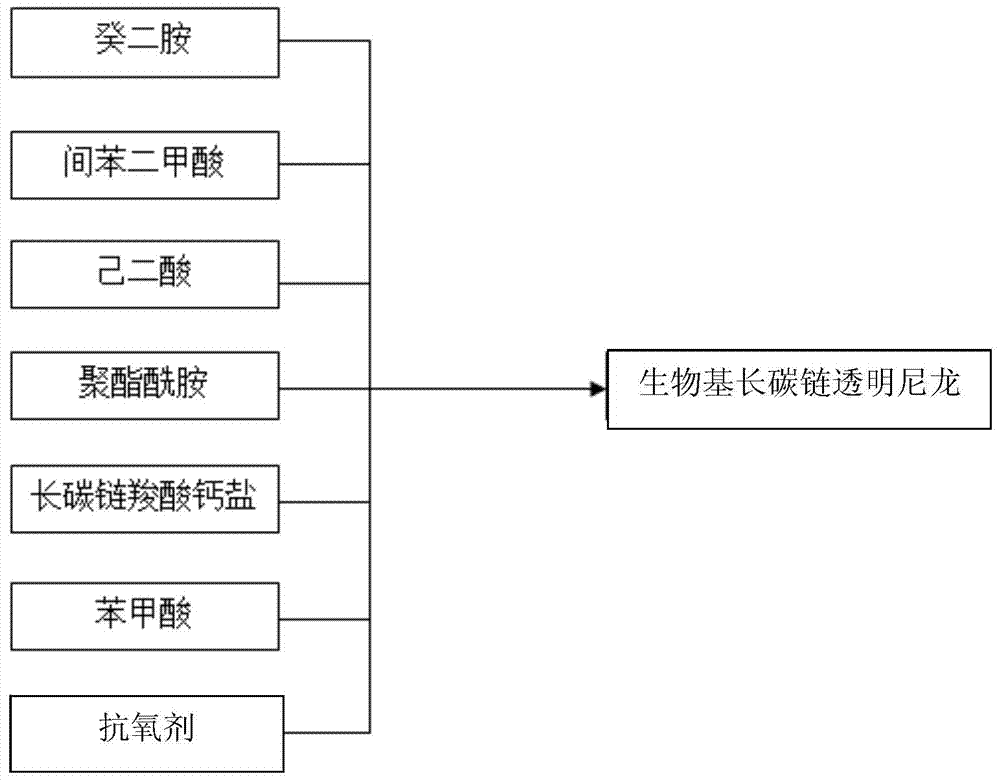

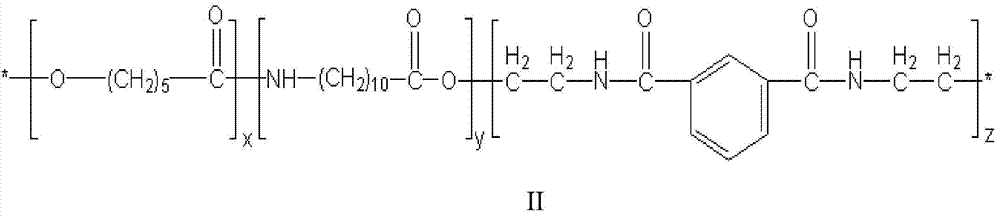

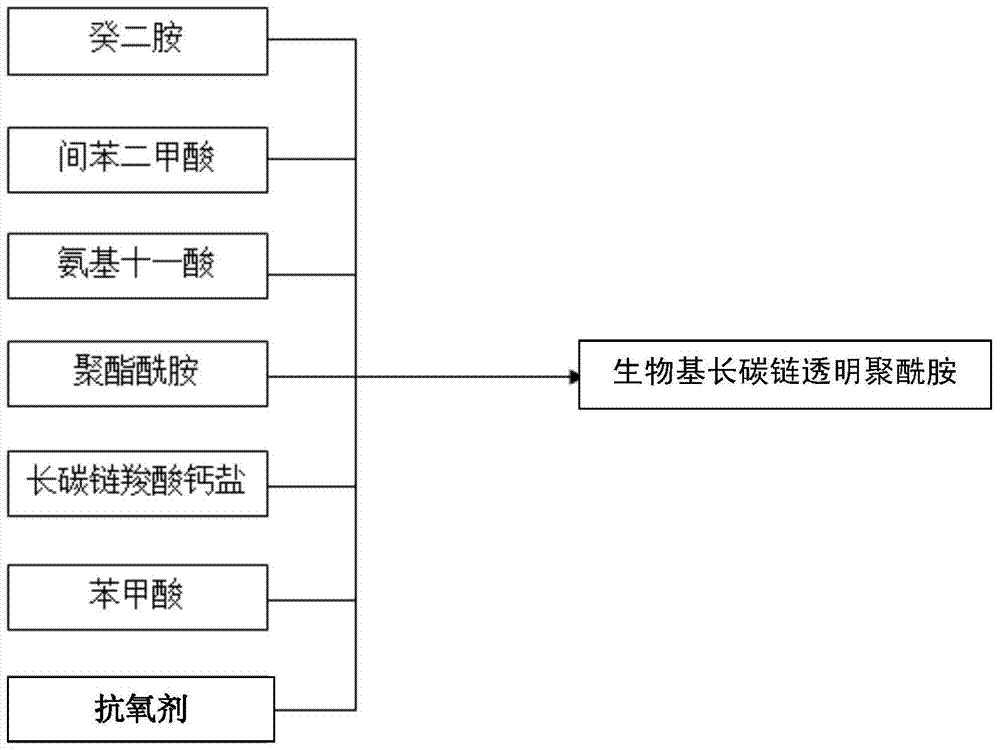

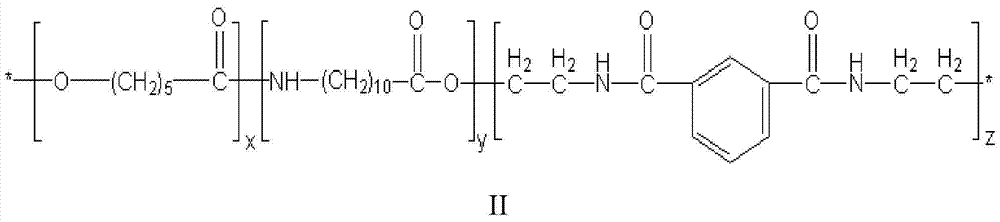

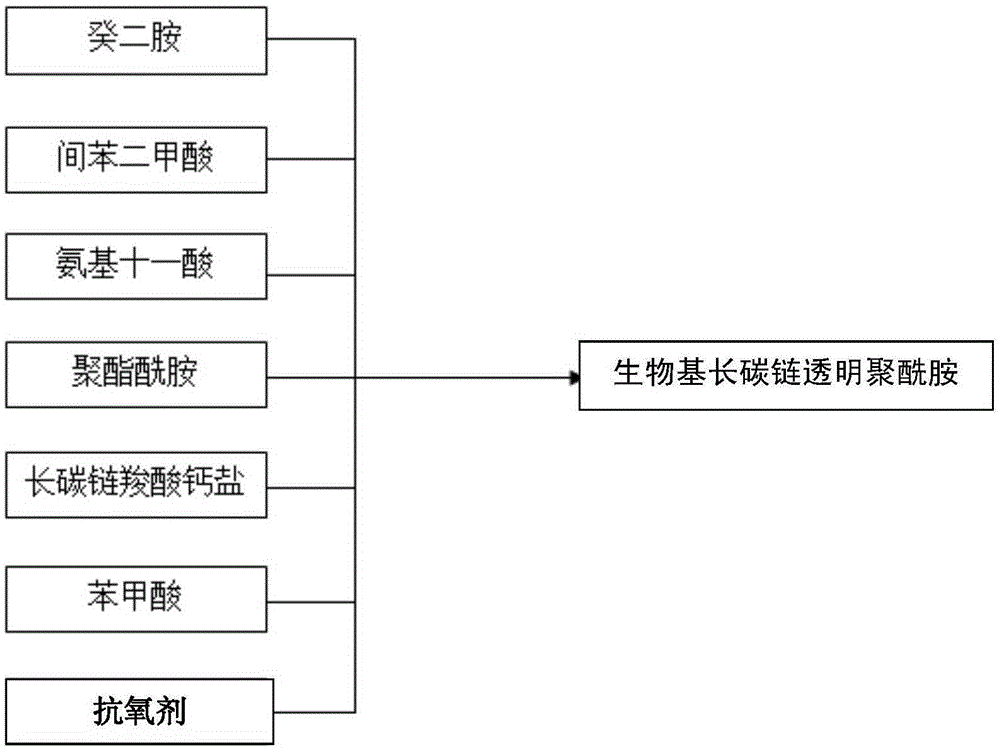

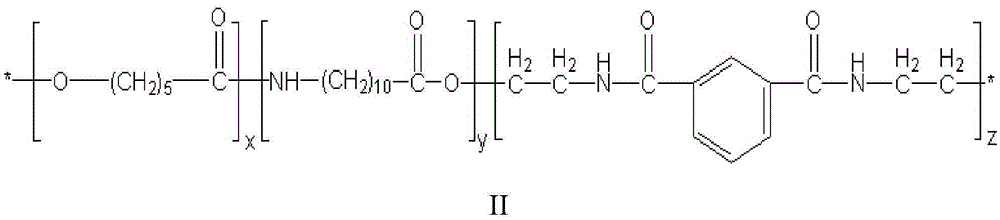

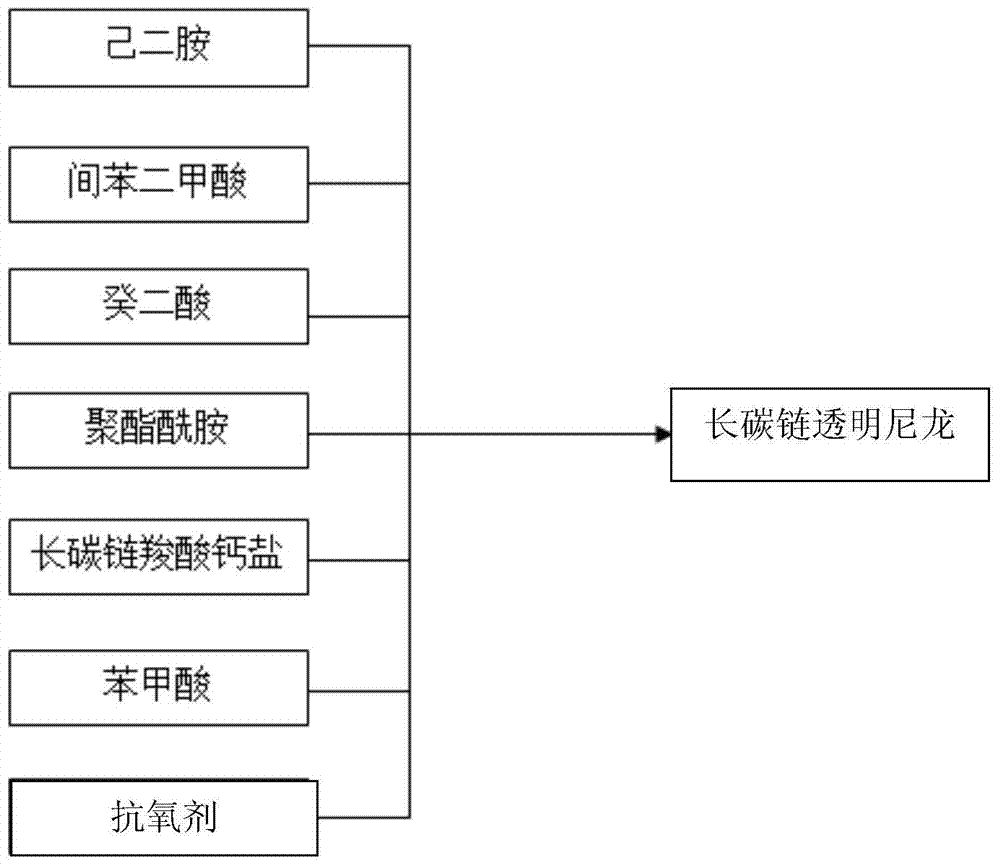

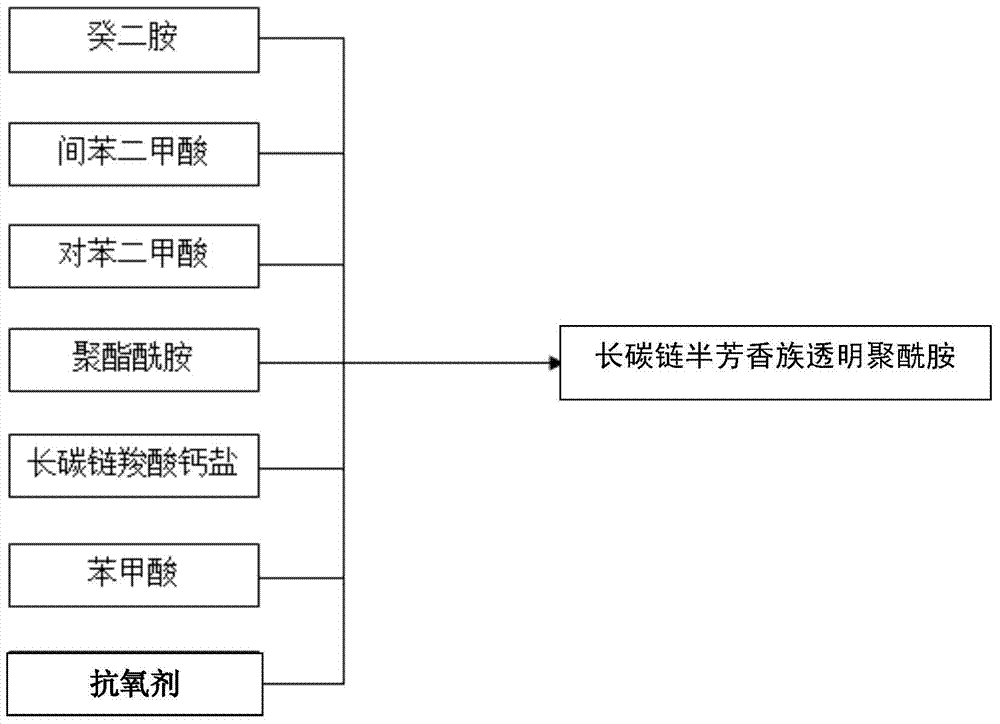

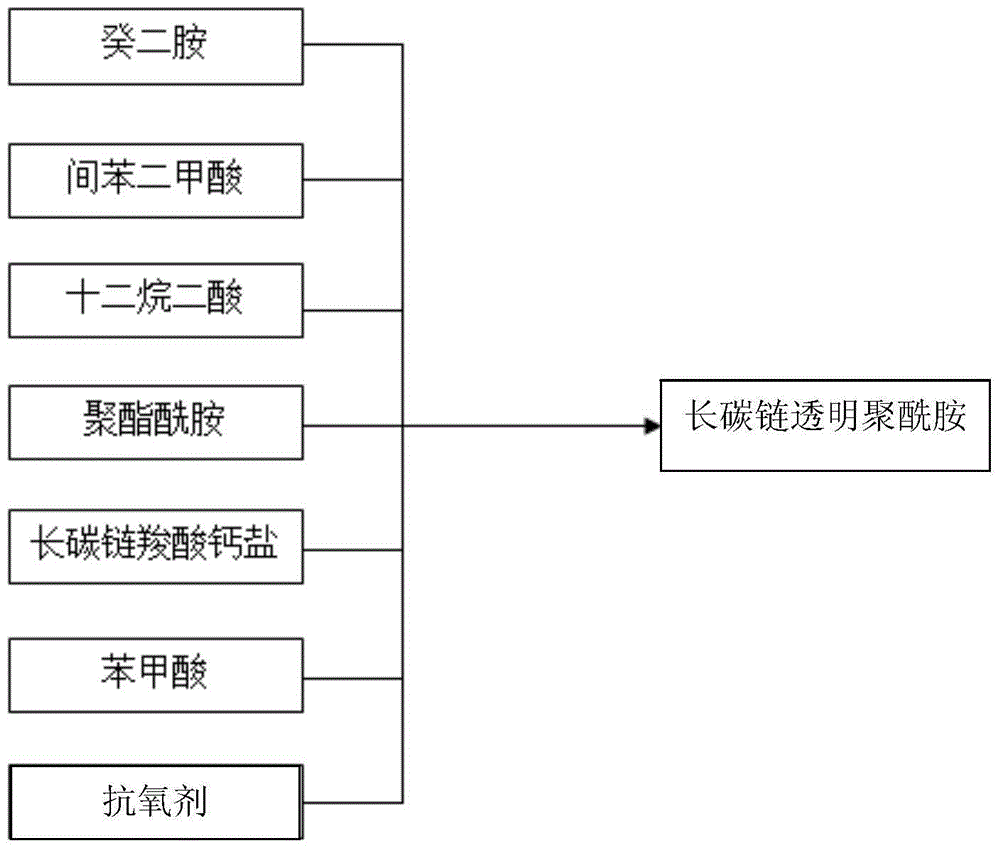

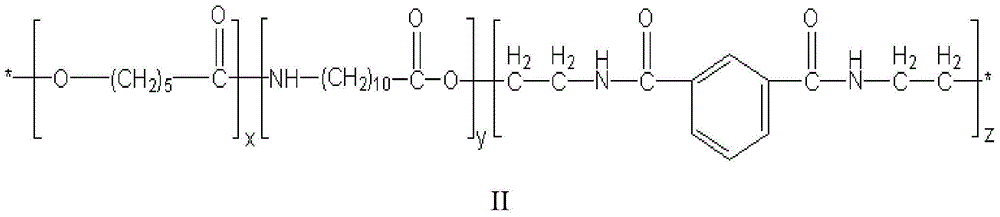

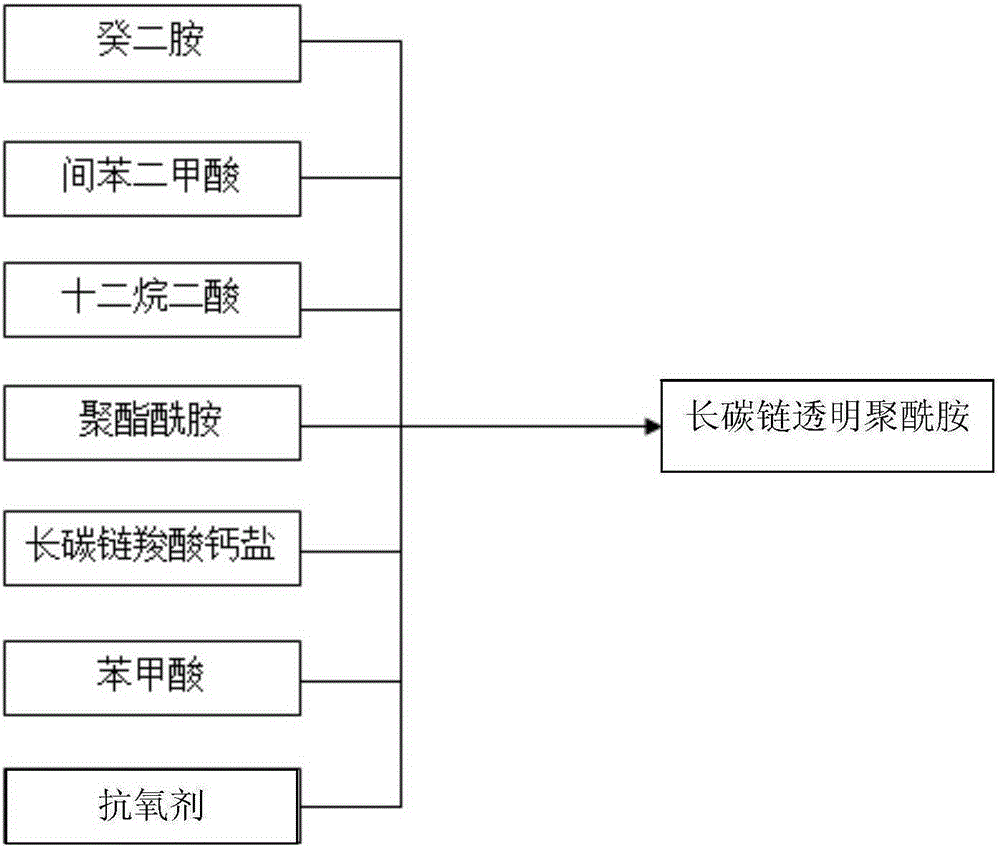

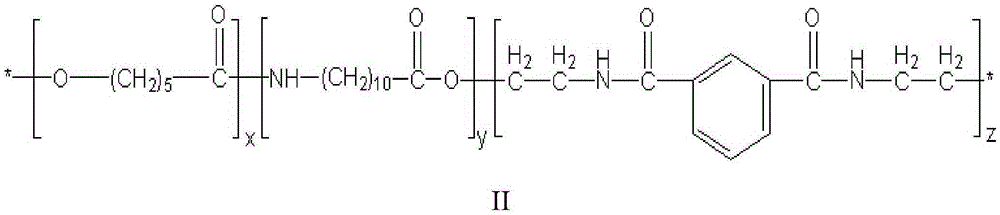

Bio-based long-carbon-chain transparent nylon and synthesis method thereof

ActiveCN105330852AImprove notched impact strengthImprove antistatic performancePolyesterSynthesis methods

The invention discloses bio-based long-carbon-chain transparent nylon and a synthesis method thereof. The bio-based long-carbon-chain transparent nylon has the structure shown in formula I as described in the description, wherein in the formula I, a is equal to 10-100, b is equal to 10-200, c is equal to 10-100, d is equal to 10-100, and R represents polyesteramide. The bio-based long-carbon-chain transparent nylon has the advantages that mechanical performance and light transmittance are high, the water absorption rate is low, the machining performance is excellent, biological sources are achieved, and the bio-based long-carbon-chain transparent nylon can be applied to the fields of surrounding mechanical parts and electrical and mechanical parts of fuel and oil, precision optical instruments, pressure-proof view windows, observation mirrors, special lamp outer covers, food packaging thin films, high-grade sports equipment and the like.

Owner:ZHONGBEI UNIV

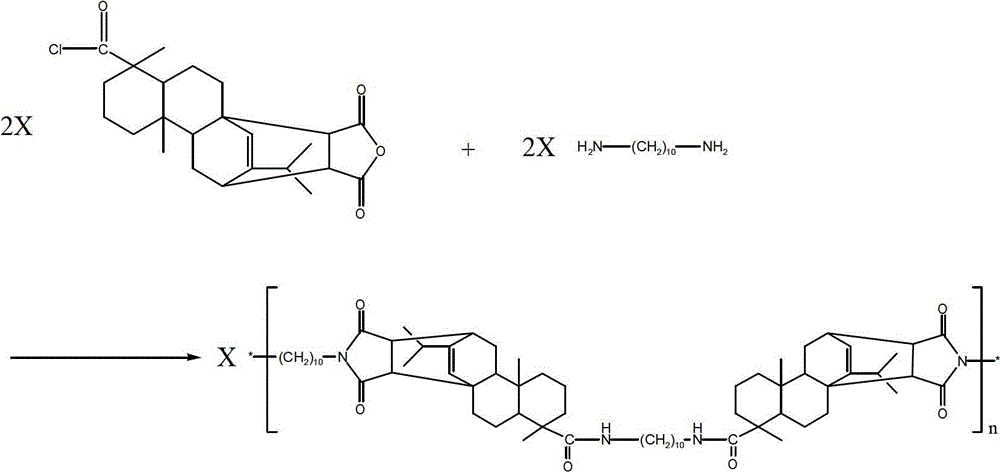

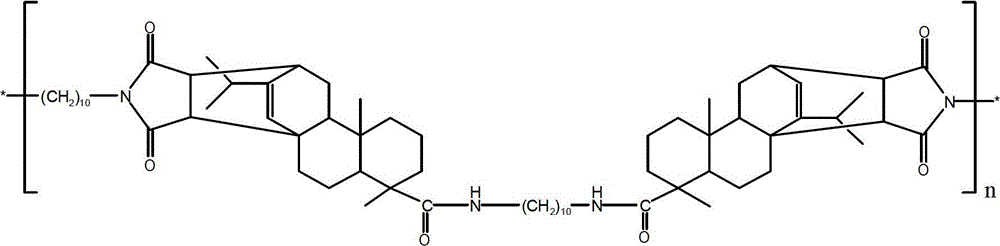

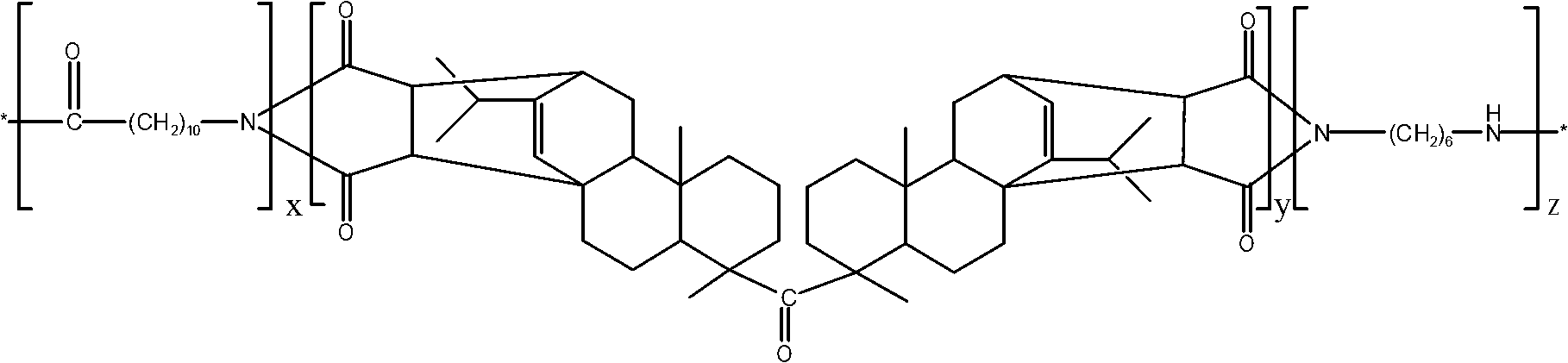

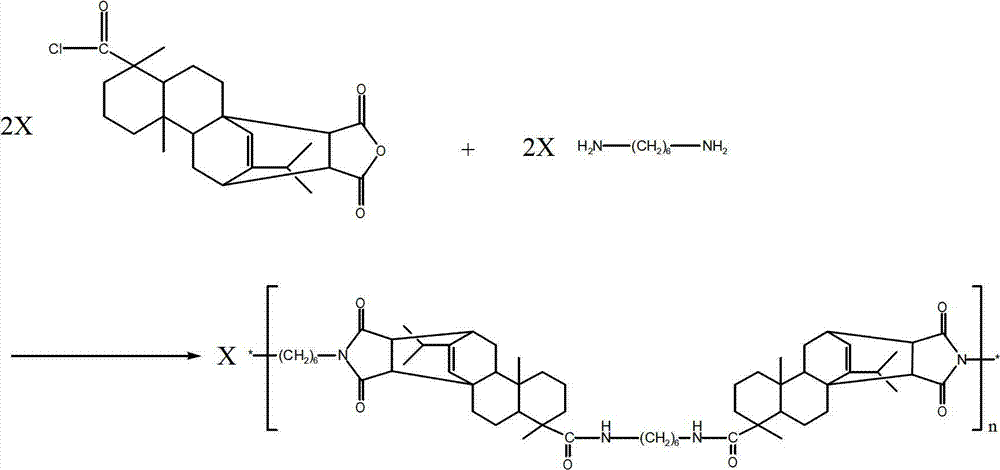

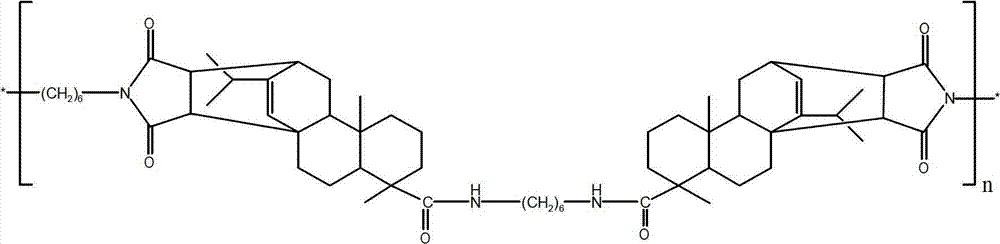

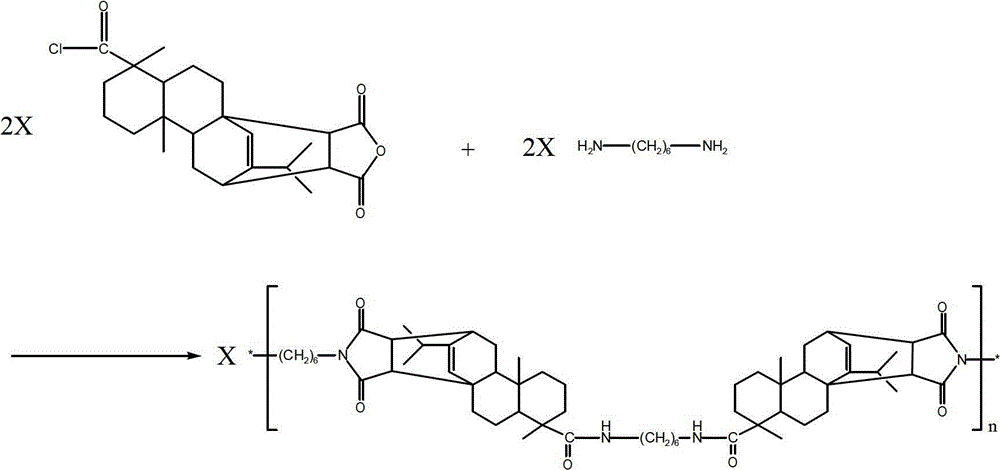

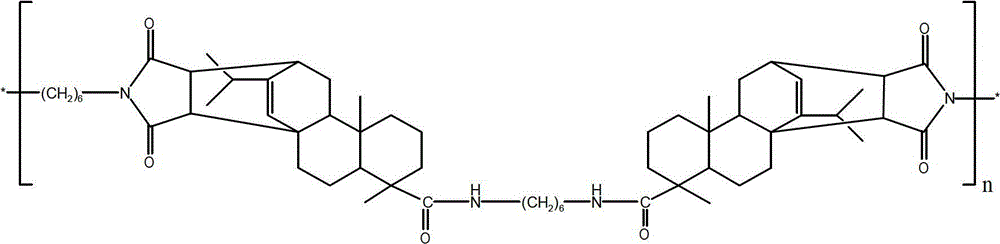

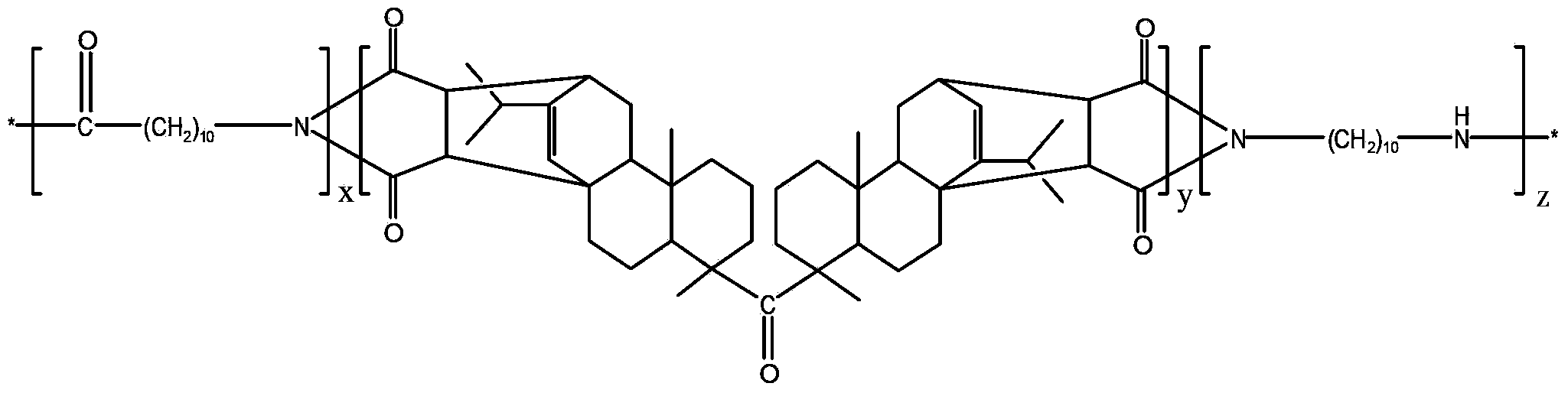

Bio-based long-carbon-chain semi-alicyclic polyamide-imide PA10I and synthesizing method thereof

The invention discloses a synthesizing method for bio-based long-carbon-chain semi- alicyclic polyimide-imide. Maleopimaric acid acyl chloride and 1,10-decamethylene diamine respectively made of gum rosin and castor oil as raw materials are put into a stirring-type polymerization reaction container; inert gases are fed after the stirring-type polymerization reaction container is vacuumized; the polymerization reaction container is heated hermetically; after the stirring speed of the polymerization reaction container is adjusted, the reactants are thermally insulated and pressurized, and the gases are discharged so as to obtain ordinary pressure; the polymerization reaction container is heated again, the stirring speed of the polymerization reaction container is adjusted, and the polymerization reaction container is continually vacuumized after constant temperature is obtained; and the bio-based long-carbon-chain semi-alicyclic polyimide is obtained after the reaction is over. The synthesizing method of the invention is based on the principle of melt polycondensation and the whole synthesis process does not require any organic solvent, so that no additional steps to recover organic solvent are needed , and no toxin or harm is generated to people and the environment. The synthesized polyamide-imide PA10I has the advantages of good heat resistance, high-temperature rigidity, dimensional stability and low water absorption. The polyamide-imide PA10I can be used for engineering plastics or film materials and the like.

Owner:SINOPLAST NEW MATERIAL

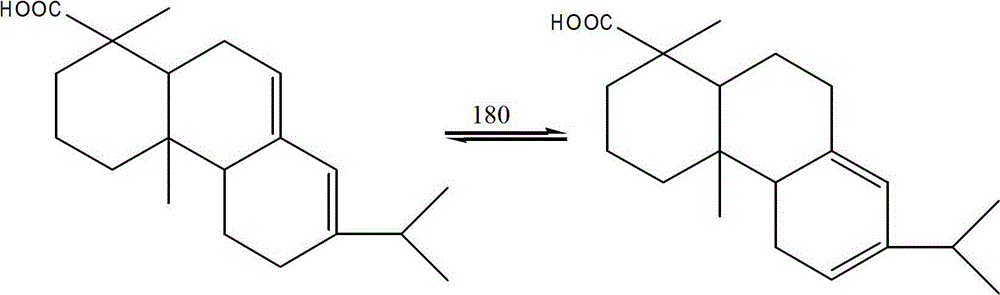

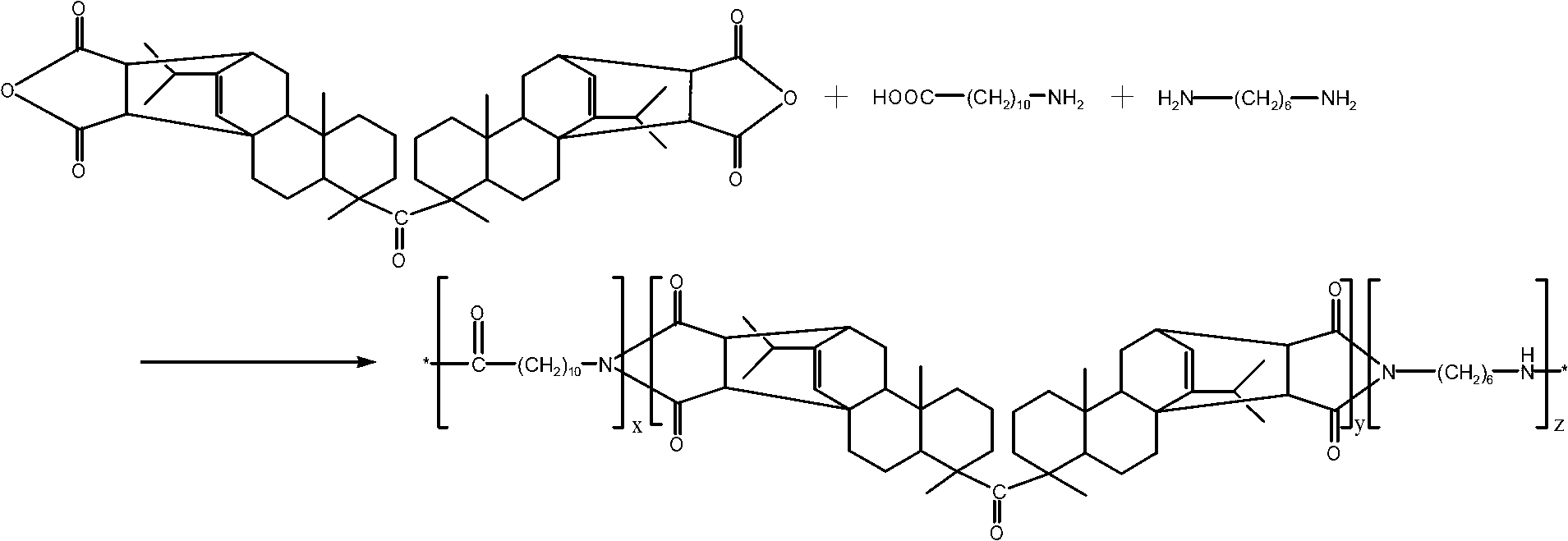

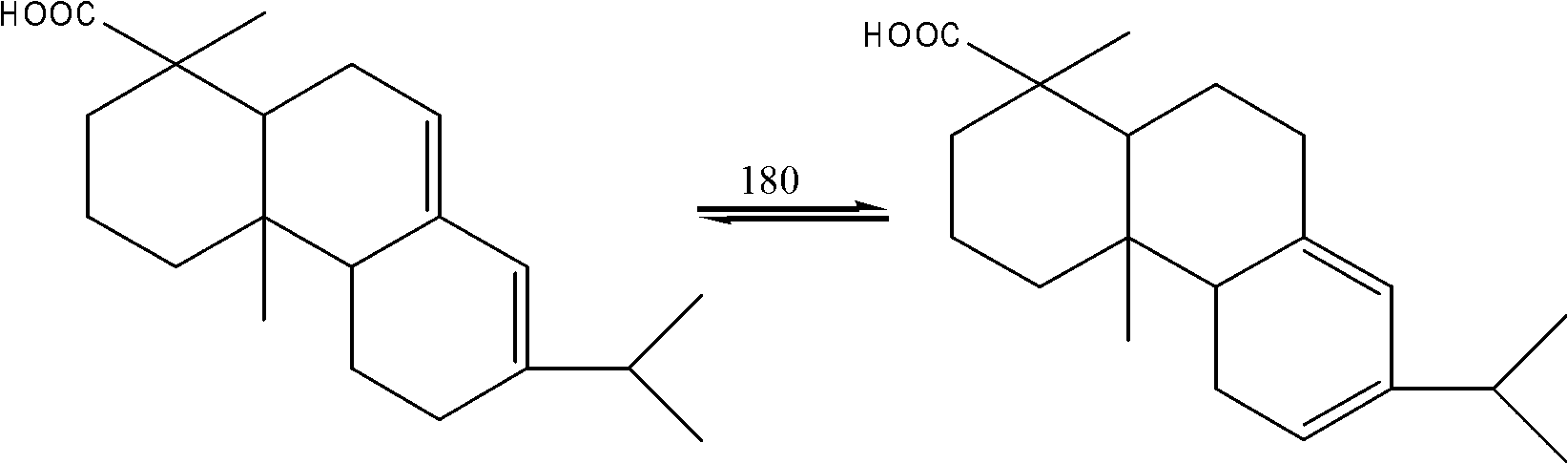

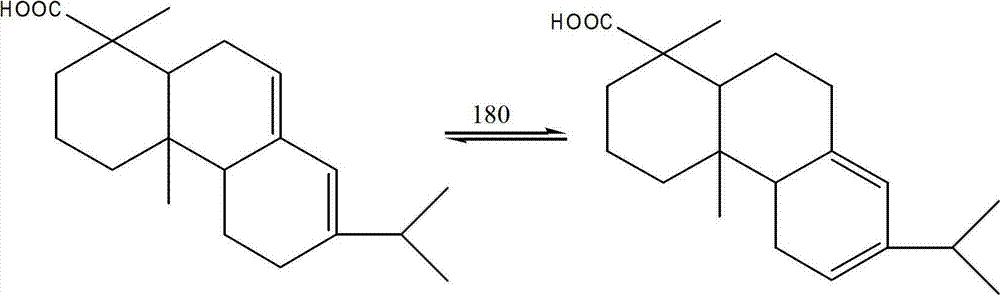

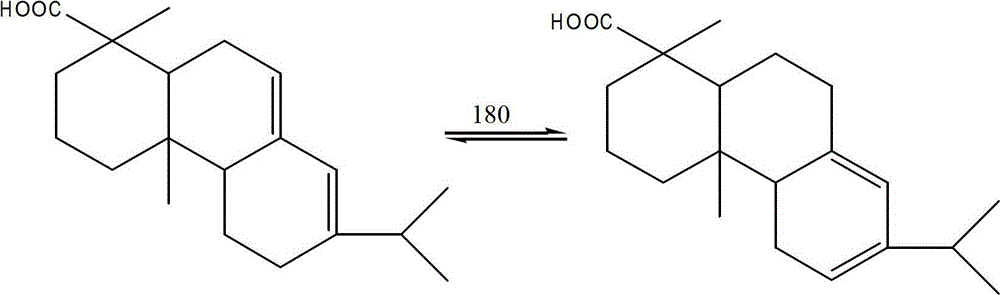

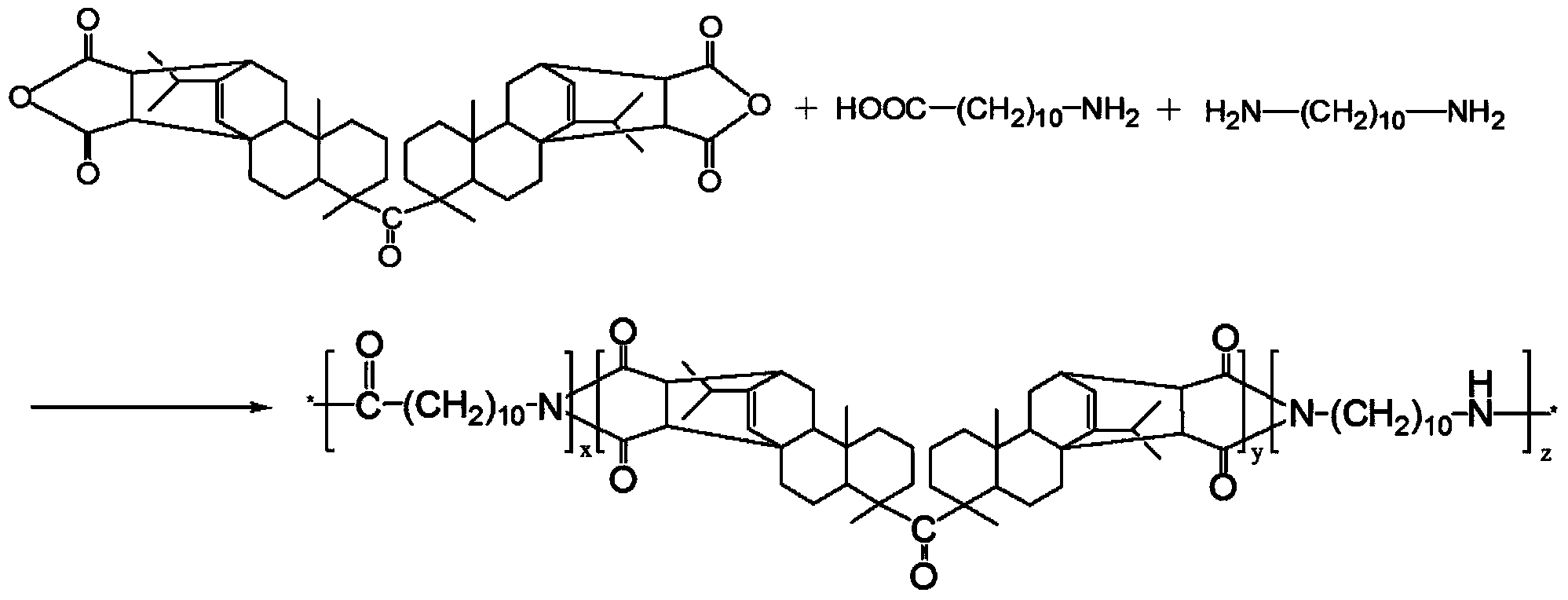

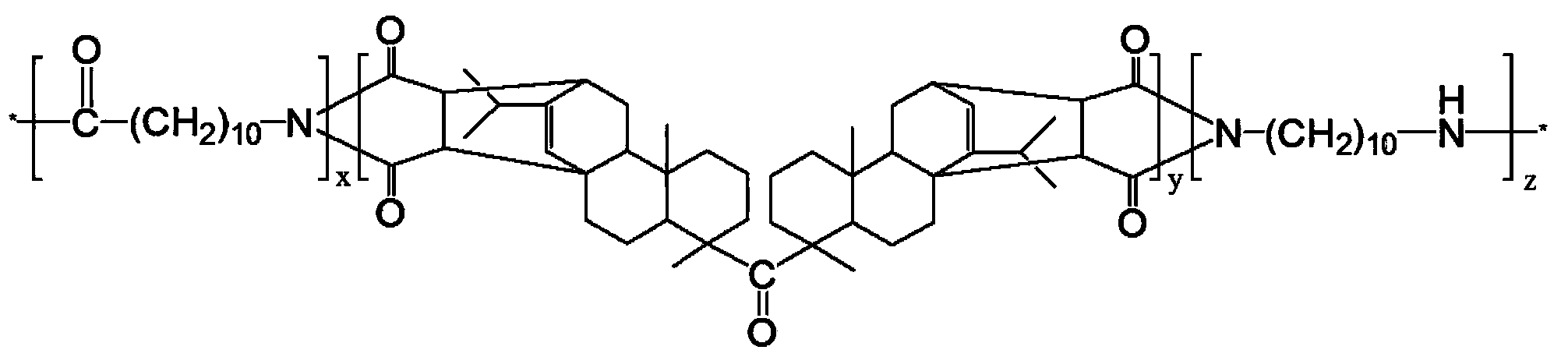

Rosin-base half alicyclic polyamide imide copolymer and synthetic method thereof

The invention discloses a rosin-base half alicyclic polyamide imide copolymer and a synthetic method thereof. According to the invention, maleopimaric acid dianhydride, 11- amino undecanoic acid and (1, 6) -hexanediamine, which are prepared by taking gum rosin and castor oil as raw materials, are added into stirring polymer reactor together, and the polymer reactor is vacuumized and then fed with inert gases; the polymer reactor is heated hermetically, the stirring rate of the polymer reactor is adjusted, then reactants are thermal insulated and pressurized, and the polymer reactor is released to normal pressure; the polymer reactor is heated once more, the stirring rate of the polymer reactor is adjusted, the polymer reactor is vacuumized continuously after reaching the constant temperature, the reaction is over, and the copolymer is obtained. The synthetic method disclosed by the invention is based on the fusion polymerization principle, and no organic solvent is used during the whole polymerization process, therefore, additional steps for recovering the organic solvent are avoided, and hazards on the human body and the environement are prevented. The polymerized polyamide imide copolymer has good thermal resistance, high-temperature rigidity, size stability and low water absorption, and can be applied to engineering plastics, membrane materials and the like.

Owner:SINOPLAST NEW MATERIAL

Long-carbon-chain semi-aromatic transparent nylon and synthesis method thereof

ActiveCN105348515AImprove notched impact strengthImprove antistatic performancePolyesterSynthesis methods

The invention discloses long-carbon-chain semi-aromatic transparent nylon and a synthesis method thereof. The long-carbon-chain semi-aromatic transparent nylon has the structure shown in the formula I (shown in the description); in the formula I, a is equal to 10-100, b is equal to 10-200, c is equal to 10-100, d is equal to 10-100, and R is polyesteramide. The long-carbon-chain semi-aromatic transparent nylon has a relatively high mechanical property, relatively high transmittance, low water absorption and excellent processabilityand can be applied to the fields of peripheral mechanical parts and electrical mechanical parts adopting fuel and oil, precision optical instruments, pressure-resistant windows, observation mirrors, special lamp outer covers, food packaging films, high-end sport equipment and the like.

Owner:ZHONGBEI UNIV

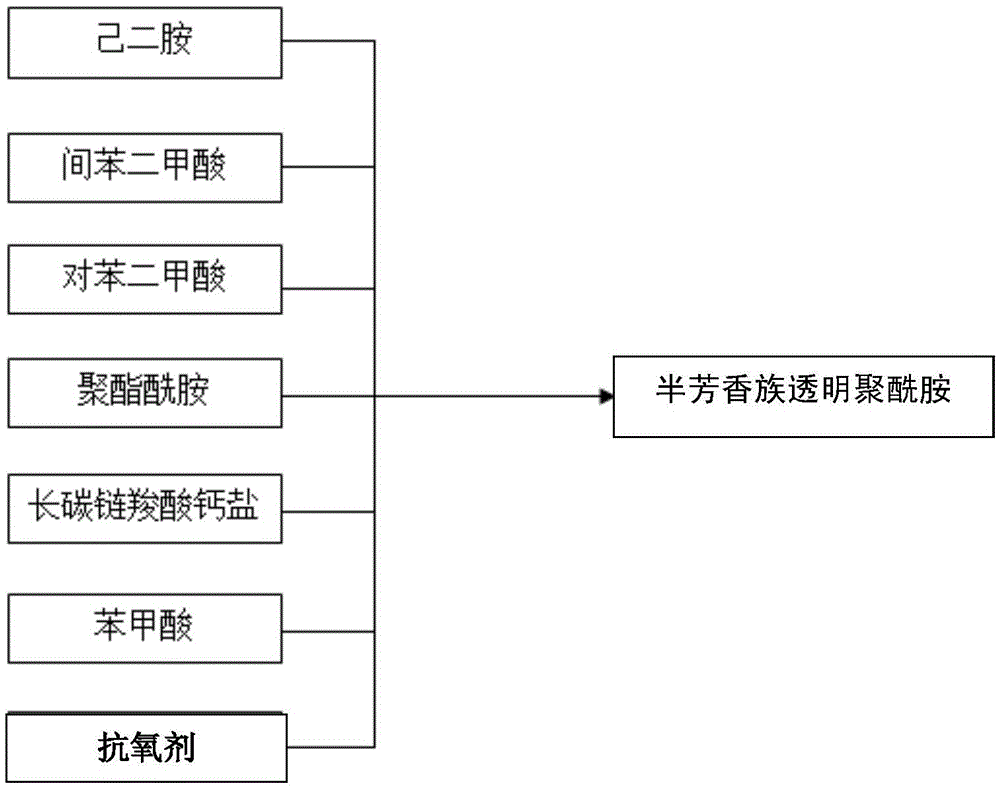

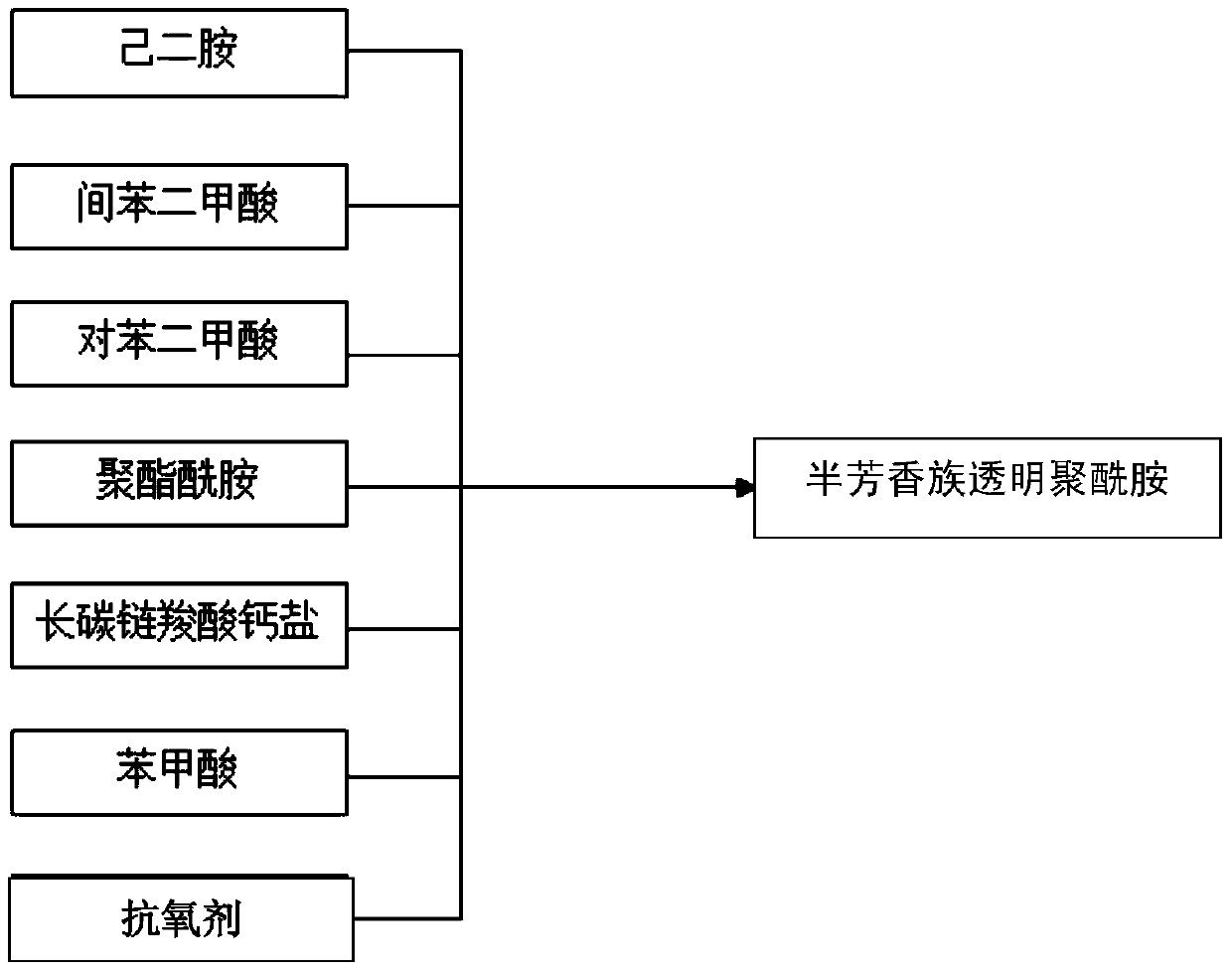

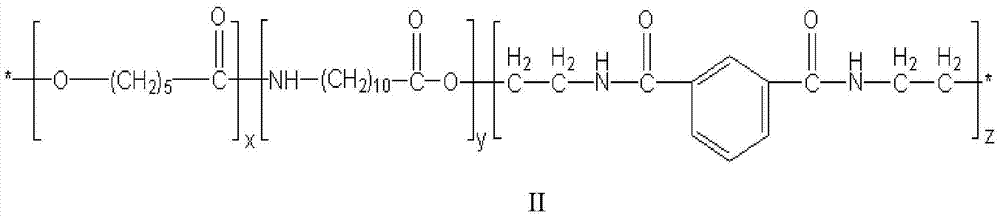

Semi-aromatic transparent polyamide and synthesis method thereof

ActiveCN105482102AReduced crystallization abilityImprove notched impact strength and antistatic abilityPolyamideOptical instrument

The invention discloses a semi-aromatic transparent polyamide and a synthesis method thereof. The semi-aromatic transparent polyamide has a structure shown in a formula I, wherein a equals to 10-100, b equals to 10-200, c equals to 10-100, d equals to 10-100, and R is a polyester amide. The semi-aromatic transparent polyamide has high mechanical properties and transmittance, low water absorption and excellent processing performance, can be applied in the mechanical parts around the fuel oil, electrical and mechanical components, precision optical instruments, pressure-resistant windows, viewers, special light fixture housing, food packaging films, and high-end sports equipment.

Owner:ZHONGBEI UNIV

Rosin-based semi-alicyclic polyamide-imide PA6I and synthesizing method thereof

The invention discloses a synthesizing method for rosin-based semi-alicyclic polyamide-imide PA6I. Maleopimaric acid acyl chloride is prepared by using gum rosin as raw materials, and the maleopimaric acid acyl chloride is dried through vacuumization; the dried maleopimaric acid acyl chloride and 1,6-hexanediamine are put into a stirring-type polymerization reaction container, and inert gases are fed after the stirring-type polymerization reaction container is vacuumized; the polymerization reaction container is heated hermetically; after the stirring speed is adjusted, the polymerization reaction container is thermally insulated and pressurized, and the gases are discharged so as to obtain ordinary pressure; and under ordinary pressure, the polymerization reaction container continues to be heated, the stirring speed is adjusted, and the polymerization reaction container is continually vacuumized after constant temperature is obtained; and the rosin-based semi-alicyclic polyamide-imidePA6I is obtained after the reaction is over. The rosin-based semi-alicyclic polyamide-imide produced by the invention is environment-friendly material, and has the advantages of good heat resistance, high-temperature rigidity, dimensional stability, and low water absorption; the preparation technique is simple, and the polymerization process is convenient, so that control and industrialization are easily achieved; and the synthesizing process is melt polycondensation with no organic solvent and no danger to people and the environment.

Owner:SINOPLAST NEW MATERIAL

Rosin-based semi-alicyclic polyamide-imide PA6I and synthesizing method thereof

ActiveCN102718969AGood securityThe preparation process is simplePolymerization reactorMaleopimaric acid

The invention discloses a synthesizing method for rosin-based semi-alicyclic polyamide-imide PA6I. Maleopimaric acid acyl chloride is prepared by using gum rosin as raw materials, and the maleopimaric acid acyl chloride is dried through vacuumization; the dried maleopimaric acid acyl chloride and 1,6-hexanediamine are put into a stirring-type polymerization reaction container, and inert gases are fed after the stirring-type polymerization reaction container is vacuumized; the polymerization reaction container is heated hermetically; after the stirring speed is adjusted, the polymerization reaction container is thermally insulated and pressurized, and the gases are discharged so as to obtain ordinary pressure; and under ordinary pressure, the polymerization reaction container continues to be heated, the stirring speed is adjusted, and the polymerization reaction container is continually vacuumized after constant temperature is obtained; and the rosin-based semi-alicyclic polyamide-imidePA6I is obtained after the reaction is over. The rosin-based semi-alicyclic polyamide-imide produced by the invention is environment-friendly material, and has the advantages of good heat resistance, high-temperature rigidity, dimensional stability, and low water absorption; the preparation technique is simple, and the polymerization process is convenient, so that control and industrialization are easily achieved; and the synthesizing process is melt polycondensation with no organic solvent and no danger to people and the environment.

Owner:广东中塑新材料股份有限公司

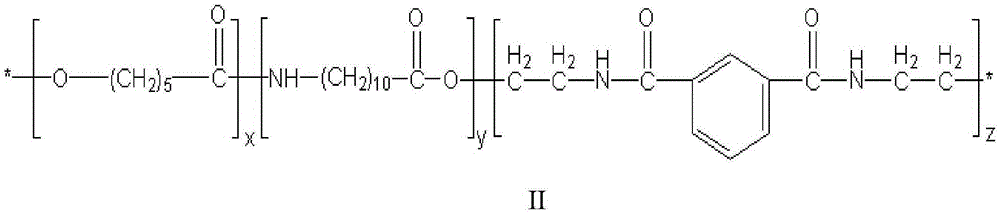

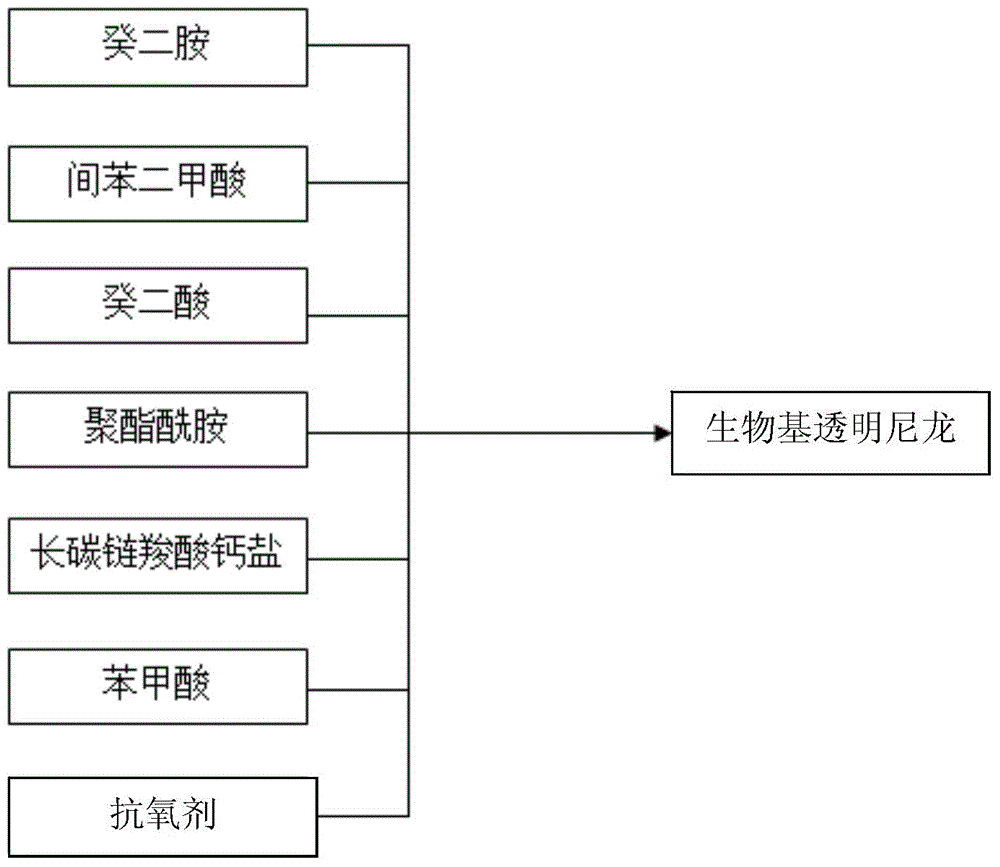

Bio-based transparent nylon and its synthesis method

ActiveCN105330845BImprove notched impact strengthImprove antistatic performancePolyesterSynthesis methods

The invention discloses bio-based transparent nylon and a synthesis method thereof. The bio-based transparent nylon has the structure shown in formula I as described in the description, wherein in the formula I, a is equal to 10-100, b is equal to 10-200, c is equal to 10-100, d is equal to 10-100, and R represents polyesteramide. The bio-based transparent nylon has the advantages that mechanical performance and light transmittance are high, the water absorption rate is low, the machining performance is excellent, biological sources are achieved, and the bio-based transparent nylon can be applied to the fields of surrounding mechanical parts and electrical and mechanical parts of fuel and oil, precision optical instruments, pressure-proof view windows, observation mirrors, special lamp outer covers, food packaging thin films, high-grade sports equipment and the like.

Owner:ZHONGBEI UNIV

Bio-based long carbon chain transparent nylon and its synthesis method

ActiveCN105330852BImprove notched impact strengthImprove antistatic performancePolyesterSynthesis methods

The invention discloses a bio-based long carbon chain transparent nylon and a synthesis method thereof. The bio-based long carbon chain transparent nylon has the following formula I structure: In formula I, a=10-100, b=10-200, c=10-100, d=10-100, R is polyester amide. The bio-based long carbon chain transparent nylon of the present invention has high mechanical properties and light transmittance, low water absorption, excellent processing performance and characteristics of biological origin, and can be applied to surrounding mechanical parts and electrical mechanical parts of fuel and oil, Precision optical instruments, pressure-resistant windows, observation mirrors, special lamp covers, food packaging films, high-end sports equipment and other fields.

Owner:ZHONGBEI UNIV

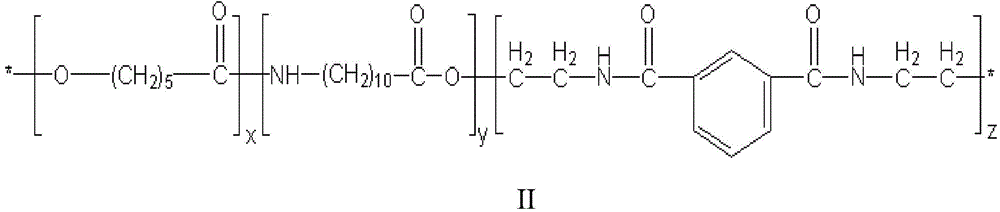

Bio-based long carbon chain transparent polyamide and its synthesis method

The invention discloses bio-based long carbon chain transparent polyamide and a synthetic method thereof. The bio-based long carbon chain transparent polyamide adopts the structure in the formula I (shown in the description), wherein a=10-200, b=10-200, c=10-100 and R is polyesteramide. The bio-based long carbon chain transparent polyamide is relatively high in mechanical property and light transmittance, low in water absorption, and excellent in processability, has the biogenetic derivation property, and can be applied to the fields of fuel and oil surrounding mechanical parts and electric mechanical parts, precise optical instruments, pressure-resistant windows, observation mirrors, special lamp shades, food packaging films, high-grade sport instruments and the like.

Owner:ZHONGBEI UNIV

Bio-based long carbon chain transparent polyamide and synthetic method thereof

ActiveCN105348517AReduced crystallization abilityImprove notched impact strength and antistatic abilityChemistryPolyester

The invention discloses bio-based long carbon chain transparent polyamide and a synthetic method thereof. The bio-based long carbon chain transparent polyamide adopts the structure in the formula I (shown in the description), wherein a=10-200, b=10-200, c=10-100 and R is polyesteramide. The bio-based long carbon chain transparent polyamide is relatively high in mechanical property and light transmittance, low in water absorption, and excellent in processability, has the biogenetic derivation property, and can be applied to the fields of fuel and oil surrounding mechanical parts and electric mechanical parts, precise optical instruments, pressure-resistant windows, observation mirrors, special lamp shades, food packaging films, high-grade sport instruments and the like.

Owner:ZHONGBEI UNIV

High temperature resistant nylon and its synthesis method

The invention discloses a high-temperature resistant nylon and a synthesis method thereof. The high-temperature resistant nylon comprises a structure shown in the formula I, wherein a=10 to 100, b=10 to 200, c=10 to 100, d=10 to 100, and R is polyester-amide. The high-temperature resistant nylon is relatively high in mechanical property and heat resistance, low in hygroscopic coefficient, and excellent in processability, and can be applied to the fields such as electronic apparatus, LEDs, automobiles, aerospace and military industry.

Owner:ZHONGBEI UNIV

Long carbon chain transparent nylon and its synthesis method

ActiveCN105330851BImprove notched impact strengthImprove antistatic performancePolyesterSynthesis methods

The invention discloses a long carbon chain transparent nylon and a synthesis method thereof. The long carbon chain transparent nylon has the following formula I structure: In formula I, a=10-100, b=10-200, c=10-100 , d=10~100, R is polyester amide. The long carbon chain transparent nylon of the present invention has high mechanical properties and light transmittance, low water absorption, excellent processing performance and biological origin, and can be applied to surrounding mechanical parts and electrical mechanical parts of fuel and oil, precision optics Instruments, pressure-resistant windows, observation mirrors, special lamp covers, food packaging films, high-end sports equipment and other fields.

Owner:ZHONGBEI UNIV

Biological based long-carbon-chain semi-alicyclic polyamidoimide copolymer and synthetic method of copolymer

Owner:深圳市中塑新材料有限公司

Semi-aromatic polyamide and its synthesis method

The invention relates to semi-aromatic polyamide and a synthesis method thereof. The semi-aromatic polyamide has the structure shown in the formula I (shown in the description); in the formula I, a is equal to 10-200, b is equal to 10-200, c is equal to 10-100 and R is polyesteramide. The semi-aromatic polyamide has a relatively high mechanical property, relatively high heat resistance, low water absorption, excellent processability and biologically-derived characteristics, and can be applied to the fields of electronics and electrical appliances, LEDs, automobiles, aerospace, military and the like.

Owner:ZHONGBEI UNIV

Semi-aromatic transparent polyamide and its synthesis method

The invention discloses a semi-aromatic transparent polyamide and a synthesis method thereof. The semi-aromatic transparent polyamide has a structure shown in a formula I, wherein a equals to 10-100, b equals to 10-200, c equals to 10-100, d equals to 10-100, and R is a polyester amide. The semi-aromatic transparent polyamide has high mechanical properties and transmittance, low water absorption and excellent processing performance, can be applied in the mechanical parts around the fuel oil, electrical and mechanical components, precision optical instruments, pressure-resistant windows, viewers, special light fixture housing, food packaging films, and high-end sports equipment.

Owner:ZHONGBEI UNIV

Bio-based semi-aromatic polyamide and its synthesis method

Owner:ZHONGBEI UNIV

Long carbon chain semi-aromatic polyamide and its synthesis method

The invention relates to a long carbon chain semi-aromatic polyamide and a synthesis method thereof. The long carbon chain semi-aromatic polyamide has the following formula I structure: in formula I, a=10-100, b=10-200, c=10-100, d=10-100, R is polyester amide. The long carbon chain semi-aromatic polyamide of the present invention has high mechanical properties and heat resistance, low water absorption, excellent processing performance and the characteristics of biological origin, and can be applied to the fields of electronic appliances, LEDs, automobiles, aerospace, etc. and military fields.

Owner:ZHONGBEI UNIV

High temperature resistant polyamide and method for synthesizing the same

The invention relates to high temperature resistant polyamide and a synthesis method thereof. The high temperature resistant polyamide has the structure as shown in the specification, wherein a=10-200, b=10-200, c=10-200, and R is polyester amide. The high temperature resistant polyamide has better mechanical properties and heat resistance, low water absorption and excellent processability and has the characteristic of biogenetic derivation, so that the high temperature resistant polyamide can be applied to the fields of electronic appliances, LEDs, vehicles, aerospace, war industry and the like.

Owner:ZHONGBEI UNIV

Bio-based high temperature resistant polyamide and its synthesis method

Owner:ZHONGBEI UNIV

Long carbon chain transparent polyamide and its synthesis method

The invention discloses long carbon chain transparent polyamide and a synthesizing method thereof. The long carbon chain transparent polyamide has the structure shown in the formula I (please see the formula in the specification). In the formula I, a ranges from 10 to 100, b ranges from 10 to 200, c ranges from 10 to 100, d ranges from 10 to 100, and R is polyesteramide. The long carbon chain transparent polyamide has high mechanical properties and light transmittance, a low water absorbing rate, excellent processing performance and characteristics of biogenetic derivation, and can be applied to surrounding mechanical parts and electric machine parts of fuel and oil, precise optical instruments, pressure-resistant windows, observation mirrors, special lamp covers, food packaging films, high-grade sports instruments and other fields.

Owner:ZHONGBEI UNIV

Long carbon chain transparent polyamide and synthesizing method thereof

The invention discloses long carbon chain transparent polyamide and a synthesizing method thereof. The long carbon chain transparent polyamide has the structure shown in the formula I (please see the formula in the specification). In the formula I, a ranges from 10 to 100, b ranges from 10 to 200, c ranges from 10 to 100, d ranges from 10 to 100, and R is polyesteramide. The long carbon chain transparent polyamide has high mechanical properties and light transmittance, a low water absorbing rate, excellent processing performance and characteristics of biogenetic derivation, and can be applied to surrounding mechanical parts and electric machine parts of fuel and oil, precise optical instruments, pressure-resistant windows, observation mirrors, special lamp covers, food packaging films, high-grade sports instruments and other fields.

Owner:ZHONGBEI UNIV

Long carbon chain semi-aromatic transparent nylon and its synthesis method

ActiveCN105348515BImprove notched impact strengthImprove antistatic performancePolyesterSynthesis methods

The invention discloses long-carbon-chain semi-aromatic transparent nylon and a synthesis method thereof. The long-carbon-chain semi-aromatic transparent nylon has the structure shown in the formula I (shown in the description); in the formula I, a is equal to 10-100, b is equal to 10-200, c is equal to 10-100, d is equal to 10-100, and R is polyesteramide. The long-carbon-chain semi-aromatic transparent nylon has a relatively high mechanical property, relatively high transmittance, low water absorption and excellent processabilityand can be applied to the fields of peripheral mechanical parts and electrical mechanical parts adopting fuel and oil, precision optical instruments, pressure-resistant windows, observation mirrors, special lamp outer covers, food packaging films, high-end sport equipment and the like.

Owner:ZHONGBEI UNIV

Long-carbon-chain semi-aromatic transparent polyamide and synthesis method thereof

The invention discloses long-carbon-chain semi-aromatic transparent polyamide and a synthesis method thereof. The long-carbon-chain semi-aromatic transparent polyamide has the structure shown in the formula I (shown in the description); in the formula I, a is equal to 10-100, b is equal to 10-200, c is equal to 10-100 and R is polyesteramide. The long-carbon-chain semi-aromatic transparent polyamide has a relatively high mechanical property, relatively high transmittance, low water absorption, excellent processability and biologically-derived characteristics, and can be applied to the fields of peripheral mechanical parts and electrical mechanical parts adopting fuel and oil, precision optical instruments, pressure-resistant windows, observation mirrors, special lamp outer covers, food packaging films, high-end sport equipment and the like.

Owner:ZHONGBEI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com