Long-carbon-chain semi-aromatic polyamide and synthetic method thereof

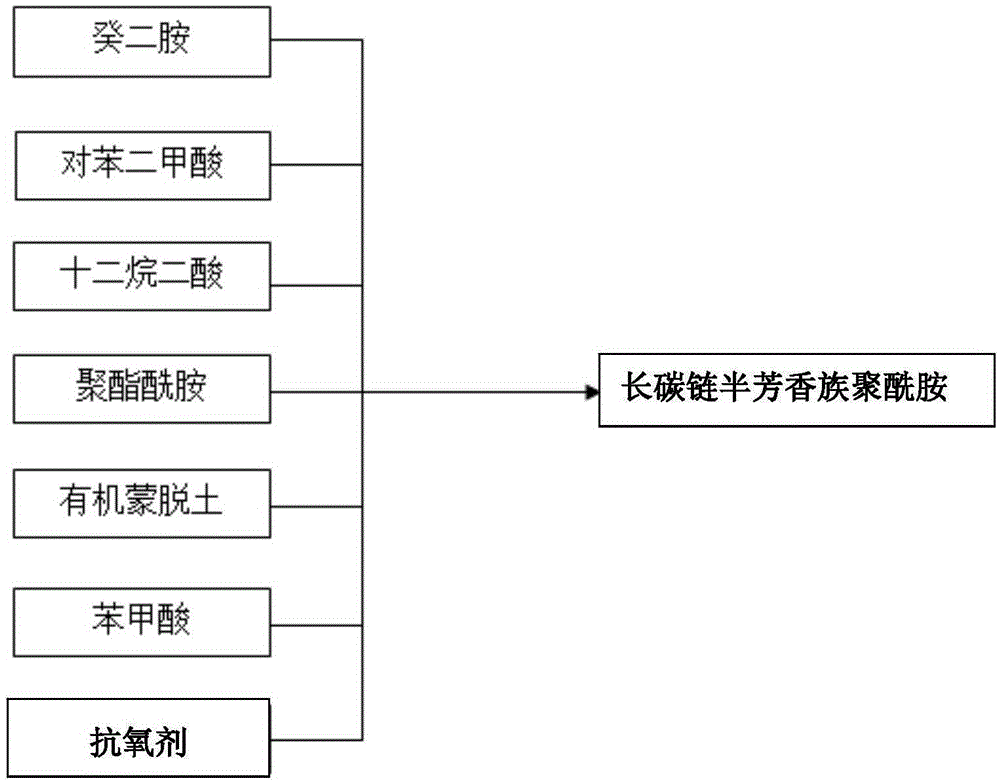

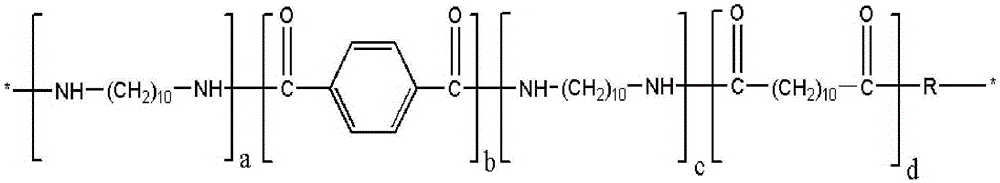

A semi-aromatic and synthetic method technology, applied in the field of materials, can solve the problems of restricting the large-scale promotion of solid-phase polymerization, accelerating the discharge of by-product small molecules, and many solid-phase polymerization production processes, so as to achieve excellent processing performance, increase productivity, The effect of reducing the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] The raw material composition and synthetic steps of the polyester amide used in the present embodiment are as follows:

[0081] (1) Vacuum-dried monomer 2: 1006.6g (5mol) 11-aminoundecanoic acid, 456.6g (4mol) 6-caprolactone, 270.3g (1.25mol) 2,2'-(1,3 -Phenylene)-bisoxazoline was added to the stirred polymerization reactor, and tetrabutyl titanate (17.3 g) of 1% of the total weight of monomer 2 was added as a catalyst, and 500 mL of water was added as a mass transfer and heat transfer Then vacuumize for 5 minutes, pass nitrogen for 5 minutes, and circulate like this for 6 times, so that the reactant exists in the environment under nitrogen protection, and the system pressure in the stirred polymerization reactor is controlled to be 0.2MPa;

[0082] (2) within 2.5 hours, heat the stirred polymerization reactor to 250°C at a uniform speed, and adjust the stirring speed of the stirred polymerization reactor to 40r / min, wherein, when the temperature of the stirred polymeri...

Embodiment 2

[0087] The raw material composition and synthesis steps of the polyester amide used in this example are the same as those in Example 1.

[0088] The synthetic method of a kind of long carbon chain semi-aromatic polyamide of the present embodiment comprises the following steps:

[0089] (1) Add monomer 1 after vacuum drying: 172.3g (1mol) decane diamine, 116.3g (0.7mol) terephthalic acid, 69.1g (0.3mol) dodecanedioic acid to the stirred polymerization reactor 8% (28.6g) of polyester amide, 8% (28.6g) of organic montmorillonite, 3% (10.7g) of benzoic acid, 0.3% (1.1g) of N ,N`-bis(2,2,6,6-tetramethyl-4-piperidinyl)-1,3-phthalamide, add 100mL water as the medium for mass transfer and heat transfer; then vacuumize for 5min, pass Nitrogen for 5 minutes, so circulated 6 times, so that the reactant exists in the environment under the protection of nitrogen, and the system pressure in the control stirred polymerization reactor is 0.2MPa;

[0090] (2) within 2 hours, heat the stirred...

Embodiment 3

[0092] The raw material composition and synthesis steps of the polyester amide used in this example are the same as those in Example 1.

[0093] The synthetic method of a kind of long carbon chain semi-aromatic polyamide of the present embodiment comprises the following steps:

[0094] (1) Add monomer 1 after vacuum drying: 172.3g (1mol) decane diamine, 149.5g (0.9mol) terephthalic acid, 23.0g (0.1mol) dodecanedioic acid to the stirred polymerization reactor 2% (6.9g) of polyesteramide, 0.5% (1.7g) of organic montmorillonite, 0.5% (1.7g) of benzoic acid, 0.2% (0.7g) of N ,N`-bis(2,2,6,6-tetramethyl-4-piperidinyl)-1,3-phthalamide, add 100mL water as the medium for mass transfer and heat transfer; then vacuumize for 5min, pass Nitrogen for 5 minutes, so circulated 6 times, so that the reactant exists in the environment under the protection of nitrogen, and the system pressure in the control stirred polymerization reactor is 0.3MPa;

[0095] (2) within 3.5 hours, heat the stirr...

PUM

| Property | Measurement | Unit |

|---|---|---|

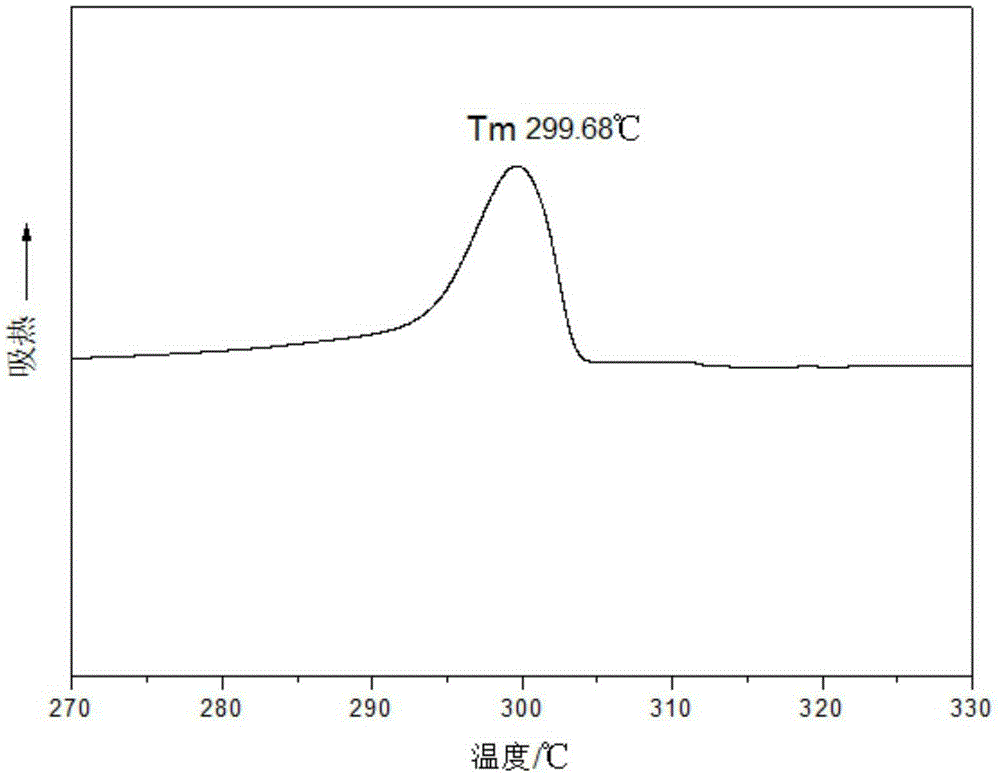

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com