High-efficiency calcium supplement capsule and preparation method thereof

A capsule and high-efficiency technology, applied in food preparation, capsule delivery, medical preparations containing active ingredients, etc., can solve the problems of not taking into account joint pain relief, increasing bone density effect, insufficient calcium absorption rate, etc., to relieve joint pain. , Increase bone strength, promote the effect of articular cartilage repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

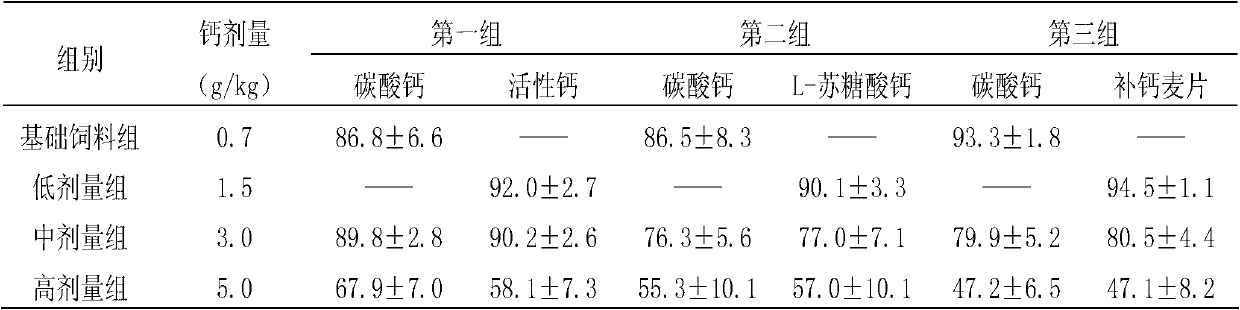

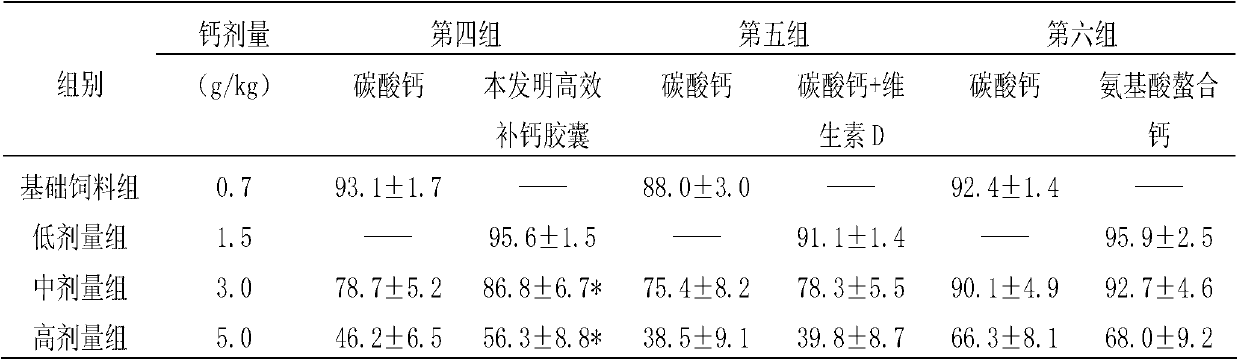

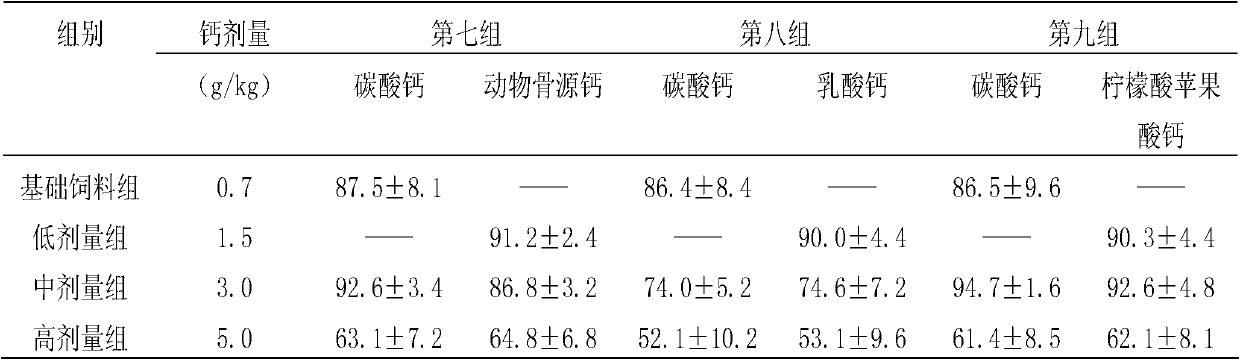

Examples

Embodiment 1

[0056] Example 1: A high-efficiency calcium supplement capsule and its preparation method

[0057] High-efficiency calcium supplement capsule formula, based on 10,000 capsules, produced in 3 batches:

[0058]

[0059] Preparation method, the steps are as follows:

[0060] (1) Pass D-glucosamine hydrochloride, chondroitin sulfate, calcium carbonate, calcium citrate malate, casein phosphopeptide, and vitamin C through an 80-mesh sieve for later use.

[0061] (2) Accurately weigh D-glucosamine hydrochloride, chondroitin sulfate, calcium carbonate, calcium citrate malate, casein phosphopeptide, and vitamin C according to the formula, and perform total mixing for 30 minutes.

[0062] (3) Fill the mixture into empty capsules.

[0063] Take the No. 0 empty capsule according to the formula, and test the car before filling, and check the difference in the filling capacity of the capsule and the disintegration time limit. The specified content of the content is 0.45g / capsule, the ...

Embodiment 2

[0065] High-efficiency calcium supplement capsule formula, based on 10,000 capsules, produced in 3 batches:

[0066]

[0067]

[0068] The preparation method is the same as in Example 1.

[0069] Below is taking embodiment 1 as test sample, to the investigation situation of the test of capsule stability. The test samples are stored under the conditions of 37-38°C and relative humidity of 70-80%, and the products are inspected and analyzed under these conditions for 0, 30, 60, and 90 days respectively. The results show that the product quality of the high-efficiency calcium supplement capsule of the present invention is stable.

[0070] Table 6 Stability test of high-efficiency calcium supplement capsules of the present invention

[0071]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com