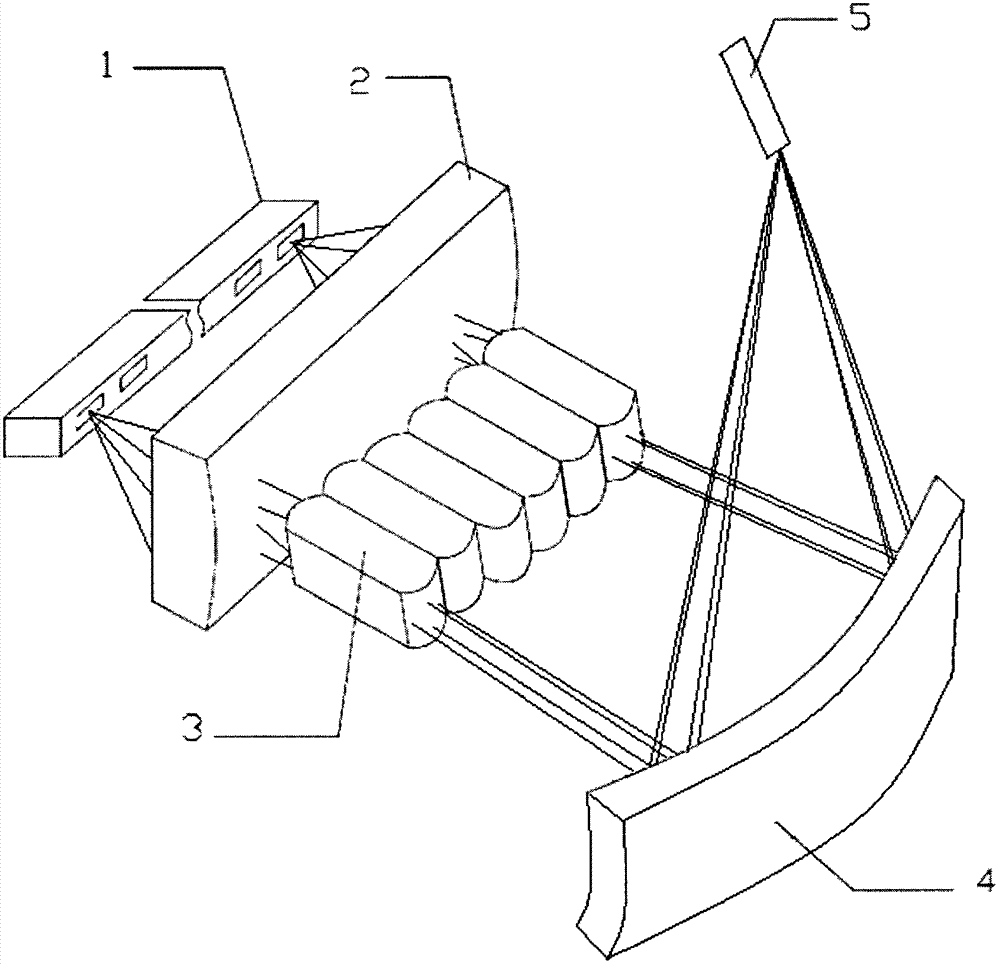

Beam coupling and focusing device for laser diode array

A laser diode and focusing device technology, applied in optics, optical components, instruments, etc., can solve problems such as multiple insertion losses, reduce system compactness, etc., and achieve the effects of small insertion loss, compact structure, and improved coupling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

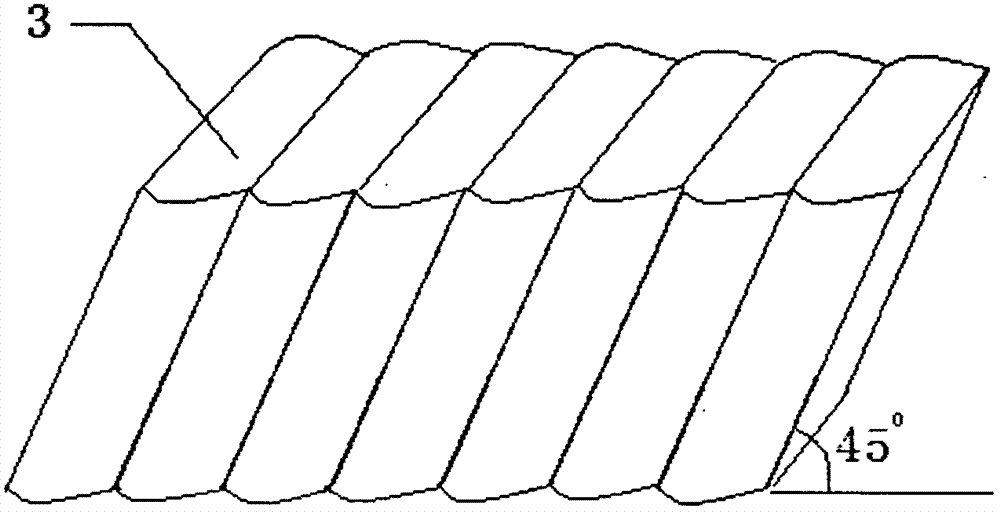

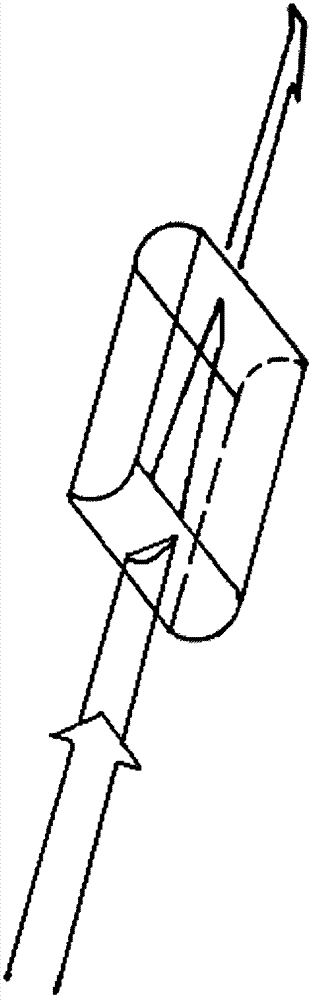

[0034] The laser diode array 1 in this embodiment is composed of 8 laser diode emitting units, and the emitting area of a single laser diode emitting unit is 1×100 μm 2 , the full-angle divergence angle of the fast axis is 35°, and the full-angle divergence angle of the slow axis is 8°. The fast-axis collimation unit 2 is a microcylindrical lens with a height of 500 μm, a thickness of 2 mm, a length of 10 mm, an optical focal length of 1 mm, and a distance of 200 μm from the laser diode array. The laser has a dielectric film with high transmittance. After the fast-axis beam emitted by the laser diode array 1 is compressed by the fast-axis collimation unit 2 to compress the fast-axis divergence angle, the fast-axis beam is shaped into a parallel beam with a height of 200 μm. The distance between the beam rotation array 3 and the fast-axis collimation unit 2 is 600 μm. The beam rotation array 3 is composed of 8 cylindrical microlens groups inclined at 45°. The main axis of a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com