Manufacturing method of poultry bifidobacteria fermented sausage

A technology of bifidobacteria and fermented sausages is applied in the field of food processing to achieve the effects of easy digestion, unique flavor, quality and safety assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

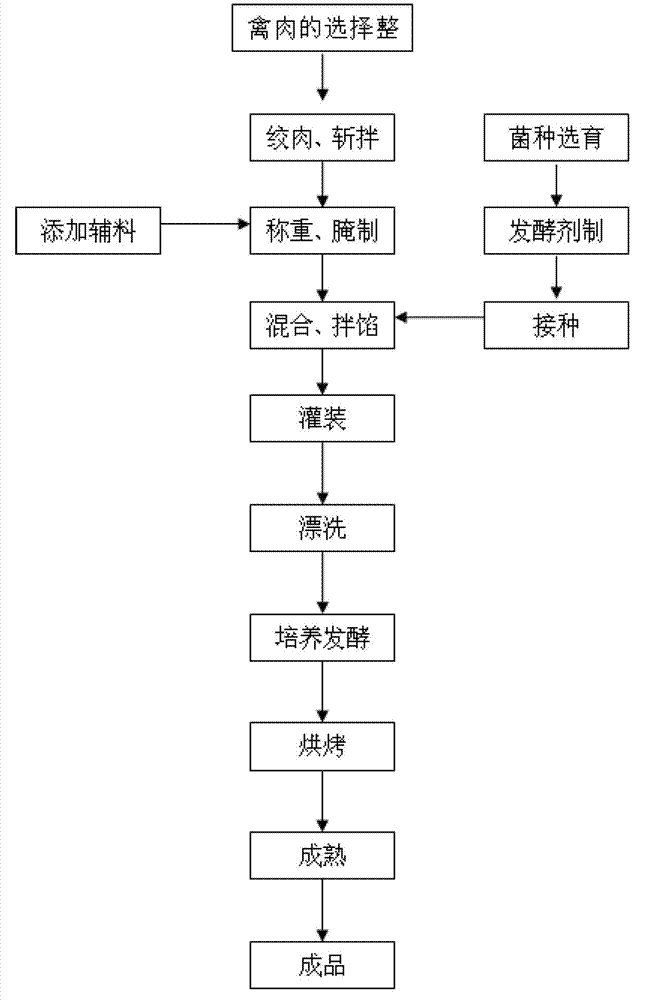

Image

Examples

Embodiment 1

[0018] Embodiment 1: the preparation method of poultry bifidobacteria fermented sausage, comprises the following steps:

[0019] (1) Select poultry meat, mince and mix, add auxiliary materials and stir evenly, and then marinate at 2-5°C for 16-20 hours; the raw materials and dosage of poultry meat and auxiliary materials are: chicken 30, duck 10, water 22.5 , starch 30, lactose 1.5, white sugar 2, monosodium glutamate 0.5, vegetable oil 3.5 and pickling agent 3; The described pickling agent is TG enzyme 0.1, salt 1.4, phosphate 0.5; Described phosphate is sodium tripolyphosphate, Sodium hexametaphosphate, sodium pyrophosphate.

[0020] (2) Prefer the strains of lactic acid bacteria, bifidobacteria, staphylococcus and micrococcus, select strong strains after isolation, domestication and cultivation, and inoculate the mixed strains according to 0.3% of the total amount of poultry meat, and mix and mix the stuffing;

[0021] (3) Filling, rinsing, cultivating and fermenting, baki...

Embodiment 2

[0023] Embodiment 2: the preparation method of poultry bifidobacteria fermented sausage, comprises the following steps:

[0024] (1) Select poultry meat, mince and mix, add auxiliary materials and stir evenly, and then marinate at 2-5°C for 16-20 hours; the raw materials and dosage of poultry meat and auxiliary materials are: chicken 30, duck 10, water 22.5 , starch 30, lactose 1.5, white sugar 2, monosodium glutamate 0.5, vegetable oil 3.5, hawthorn powder 1.5, houttuynia powder 0.2 and pickling agent 3; the pickling agent is TG enzyme 0.1, salt 1.4, phosphate 0.5; Described phosphate is sodium tripolyphosphate, sodium hexametaphosphate, sodium pyrophosphate.

[0025] (2) Prefer the strains of lactic acid bacteria, bifidobacteria, staphylococcus and micrococci, select strong strains after isolation, domestication and cultivation, and inoculate the mixed strains according to 0.3% of the total amount of poultry meat, and mix and mix the stuffing;

[0026] (3) The fermented pou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com