Artificial wood board and manufacture method thereof

A production method and wood board technology, which are applied in the directions of wood layered products, chemical instruments and methods, and manufacturing tools, can solve the problems of aggravated lung infection, aggravated ozone pollution, and the outer diameter of trees cannot meet the needs of production, and achieve structural Simple, improved structural performance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the above features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings, but the present invention is not limited thereto.

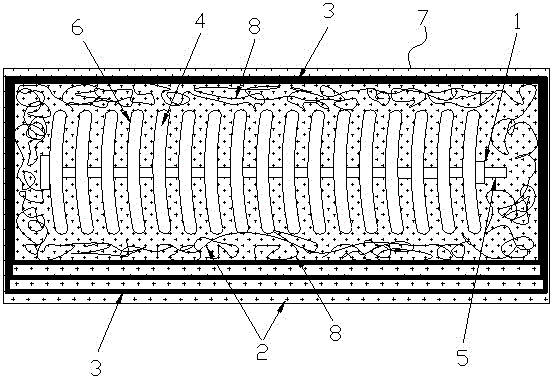

[0029] Referring to the legend, a wood-like board is characterized in that it includes a bamboo frame 1 embedded in a slurry layer 2 made of composite material filled with bamboo filaments 8; embedded with At least one layer of slurry layer is arranged above and below the slurry layer of the bamboo frame, and glass fiber cloth and non-woven fabric 3 are arranged between each layer of slurry layer.

[0030] Described bamboo frame is spliced by bolt 5 by several erected bamboo slices 4, see figure 1 , the figure shows a schematic diagram of the imitation plank width direction, and the bamboo pieces are all long strips, which are fixed by bolts at intervals in the length direction to ensure that no bending deformation will...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com