Process for producing organic fertilizer by livestock and poultry manure composting

A technology of livestock and poultry manure and organic fertilizer, applied in the direction of organic fertilizer, organic fertilizer preparation, bio-organic part treatment, etc., can solve the problems of livestock and poultry manure pollution, and achieve the effect of solving pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The process of producing organic fertilizer by decomposing livestock and poultry manure is as follows:

[0017] ①. Dehydrate and dry the livestock and poultry manure and straw separately, pulverize to a particle size of 0.5-0.8mm, and mix the mixture at a weight ratio of 5.5:2.

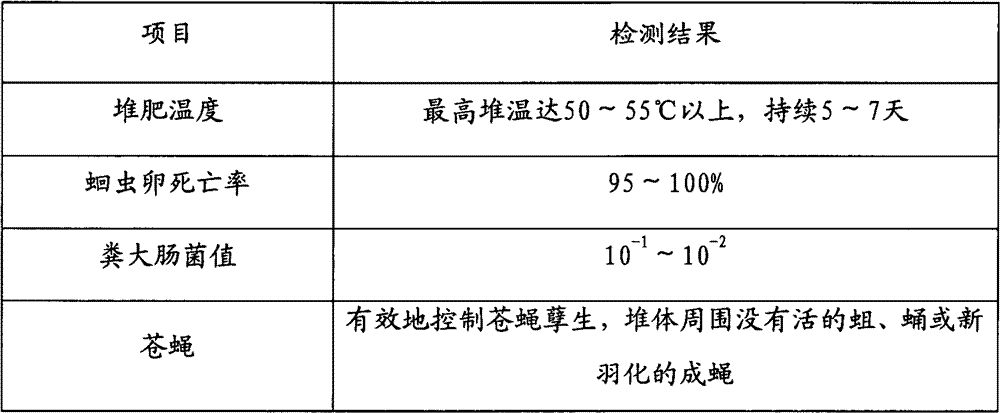

[0018] ②. According to the weight ratio of the mixture to the decomposing fungus, the ratio is 7500:2, and the decomposing fungus is mixed. The decomposing fungus contains cellulase, hemicellulase and lignin in a mass ratio of 1:1.5:1.5:0.5. Enzymes and proteases. Add water to a water content of 32%, and ferment at a high temperature of 54°C for 7 days.

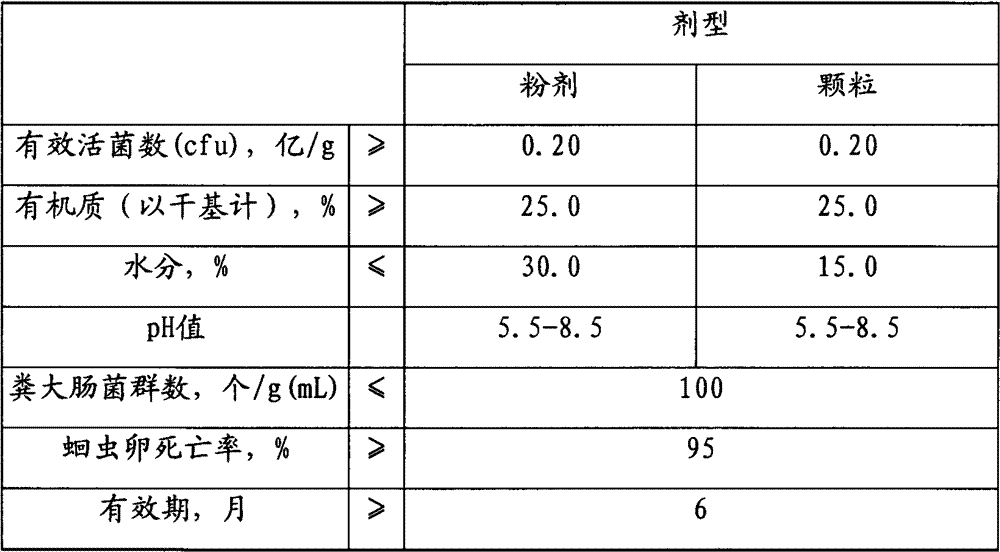

[0019] ③. Prepare powder or granule organic fertilizer according to the existing technology.

Embodiment 2

[0021] The process of producing organic fertilizer by decomposing livestock and poultry manure is as follows:

[0022] ①. Dehydrate and dry the livestock and poultry manure and straw separately, pulverize to a particle size of 0.8-1.3mm, and mix the mixture at a weight ratio of 8:1.

[0023] ②. According to the weight ratio of the mixture and the decomposing fungus, the ratio is 12000:2, and the decomposing fungus is mixed, and the decomposing fungus contains cellulase, hemicellulase and lignin with a mass ratio of 2:1.5:0.7:1.5. Enzymes and proteases. Add water to 30% water content and ferment at 52°C for 6 days.

[0024] ③. Prepare powder or granule organic fertilizer according to the existing technology.

Embodiment 3

[0026] The process of producing organic fertilizer by decomposing livestock and poultry manure is as follows:

[0027] ①. Dehydrate and dry the livestock and poultry manure and straw separately, crush them to a particle size of 1.3~1.7mm, and mix them at a weight ratio of 5.5:1 to obtain a mixture.

[0028] ②. According to the weight ratio of the mixture and the decomposing fungus, the ratio is 7500: 1.5, and the decomposing fungus is mixed, and the decomposing fungus contains cellulase, hemicellulase and lignin with a mass ratio of 2.5: 1.5: 1.5: 0.8. Enzymes and proteases. Add water to a water content of 30.5%, and ferment at a high temperature of 53°C for 5 days.

[0029] ③. Prepare powder or granule organic fertilizer according to the existing technology.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com