Low-smoke halogen-free flame-retardant thermoplastic elastomer and preparation method thereof

A technology of thermoplastic elastomers and elastomers, applied in the field of thermoplastic polymer materials, can solve problems affecting the mechanical properties and processing properties of polymer matrix resins, adverse effects on the ecological environment, and poor compatibility of polymers, so as to solve the impact on the ecological environment , high recycling rate, and the effect of reducing the amount of smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with embodiment the present invention is described in further detail.

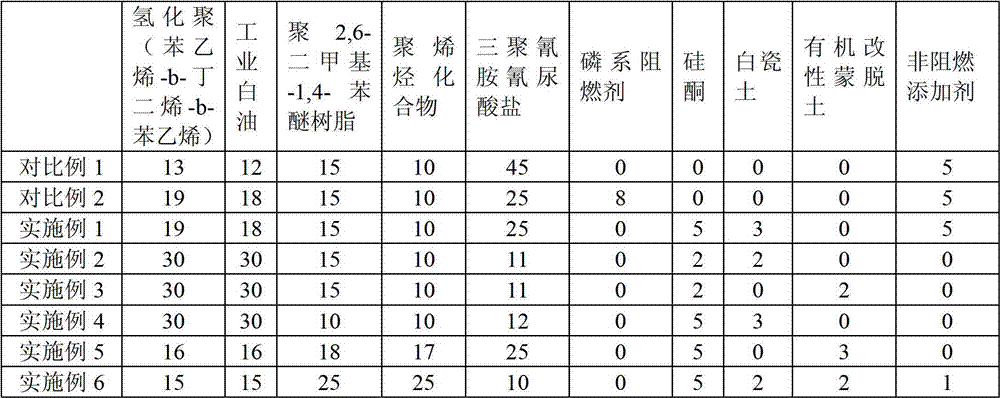

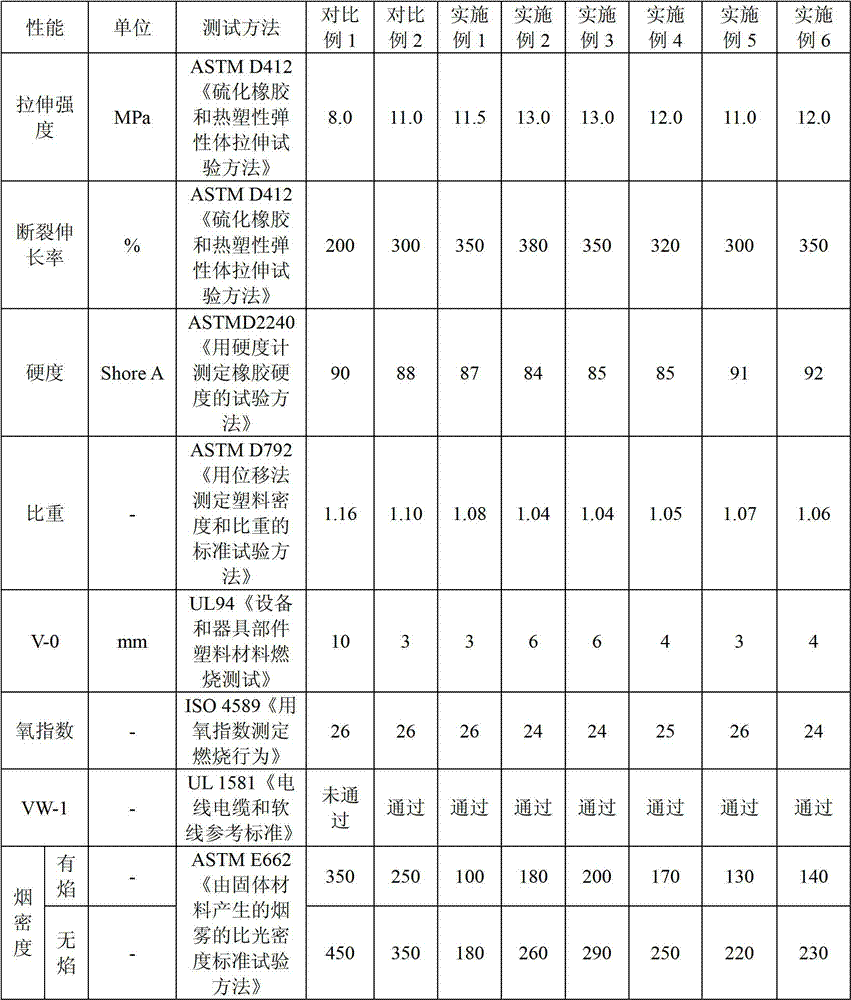

[0032] As a comparison, two comparative examples were selected for comparison with the examples. The nitrogen-based flame retardant of comparative example 1, namely melamine cyanurate, was added in a large amount. object system. The various performances of the comparative examples and the examples were tested, and the examples were prepared by the preparation method of the present invention. See Table 1 below for the proportions by weight of the Examples and Comparative Examples, and Table 2 below for their properties and comparative results.

[0033] Table 1: The weight percentage ratio (%) of embodiment and comparative example

[0034]

[0035] Table two: performance and comparison result of embodiment and comparative example

[0036]

[0037] It can be seen that the low-smoke, halogen-free flame-retardant thermoplastic elastomer of the present invention has a simple ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com