Supersonic reaction procedure of biodiesel extraction technology

A biodiesel, ultrasonic technology, applied in the petroleum industry, biofuel, liquid carbon-containing fuel, etc., can solve the problems of uneven stirring, difficult quality assurance, low production efficiency, etc., to shorten the reaction time and reduce the production cost. , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

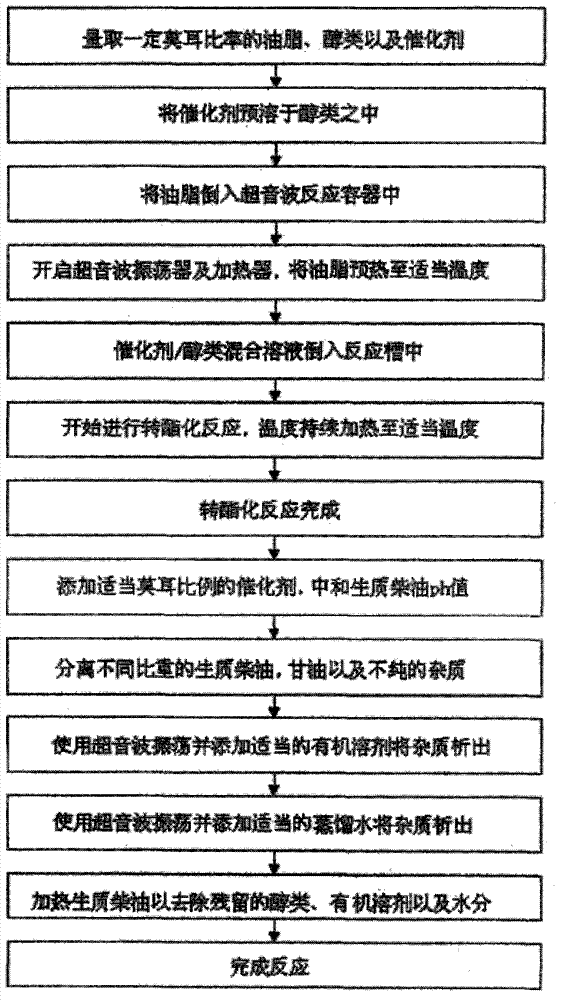

[0037] Such asfigure 1 Shown, a kind of ultrasonic reaction process of biodiesel refining technology of the present invention comprises the following steps:

[0038] The first step is to measure animal fat and methanol with a molar ratio of 1:20;

[0039] In the second step, the alkaline catalyst sodium hydroxide is predissolved in methanol, the weight of the alkaline catalyst sodium hydroxide is 1% of the animal fat weight, and the catalyst / alcohol mixed solution is obtained;

[0040] The third step is to pour the animal fat into the ultrasonic reaction container, turn on the heater, heat the animal fat to 80°C, and activate the ultrasonic vibration mechanism at the same time. The frequency of the ultrasonic vibration is 30KHz;

[0041] The fourth step is to continue to use ultrasonic vibration, the frequency of ultrasonic vibration is 30KHz, and pour the catalyst / alcohol mixed solution obtained in the second step into animal fat, and heat it to 60°C for transesterification r...

Embodiment 2

[0044] The ultrasonic reaction process of a kind of biodiesel refining technology of the present invention comprises the following steps:

[0045] The first step is to measure vegetable oil and ethanol with a molar ratio of 1:10;

[0046] In the second step, the basic catalyst potassium hydroxide is pre-dissolved in ethanol, and the weight of the basic catalyst potassium hydroxide is 0.5% of the vegetable oil weight to obtain a catalyst / alcohol mixed solution;

[0047] The third step is to pour the vegetable oil into the ultrasonic reaction container, turn on the heater, heat the vegetable oil to 60°C, and activate the ultrasonic vibration mechanism at the same time. The frequency of the ultrasonic vibration is 50KHz;

[0048] The fourth step is to continue to use ultrasonic vibration, the frequency of ultrasonic vibration is 50KHz, pour the catalyst / alcohol mixed solution obtained in the second step into vegetable oil, heat to 70°C for transesterification reaction, and obtain...

Embodiment 3

[0051] The ultrasonic reaction process of a kind of biodiesel refining technology of the present invention comprises the following steps:

[0052] The first step, measure waste oil and n-propanol that the molar ratio is 1:30;

[0053] In the second step, the basic catalyst potassium hydroxide is pre-dissolved in n-propanol, and the weight of the basic catalyst potassium hydroxide is 4% of the waste oil weight to obtain a catalyst / alcohol mixed solution;

[0054] The third step is to pour the waste oil into the ultrasonic reaction container, turn on the heater, heat the waste oil to 90°C, and activate the ultrasonic vibration mechanism at the same time. The frequency of the ultrasonic vibration is 70KHz;

[0055] The fourth step is to continue to use ultrasonic vibration, the frequency of ultrasonic vibration is 70KHz, and pour the catalyst / alcohol mixed solution obtained in the second step into the waste oil, and heat it to 80°C for transesterification reaction to obtain the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com