Accessory ingredient used for bleaching slurry oxygen delignification and application thereof

Oxygen delignification and pulping technology, applied in fiber raw material processing, cellulose pulp post-processing, papermaking, etc., can solve the problems of poor effect, affecting the improvement of whiteness of bleached pulp, high interfacial tension, etc., to achieve Improve the rate of penetration and uniform diffusion, improve lignin removal rate, and reduce production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Weigh 5kg of sodium dodecylbenzenesulfonate, 10kg of sodium lignosulfonate, 15kg of anthraquinone derivatives, 65kg of sodium sulfite, and 5kg of sodium tripolyphosphate. Among them, the manufacturer of anthraquinone derivatives is Chongqing Leapfrog (Group) Hunan Xiangyu Chemical Co., Ltd., a subsidiary of the company. Mix the above components uniformly at room temperature for no less than 30 minutes to form the oxygen bleaching aid.

[0027] Get the unbleached bamboo pulp of slurry concentration 10%, pass into the oxygen of oxygen pressure 0.5MPa, the quality that adds NaOH accounts for 2.5% of slurry dry weight, adds and accounts for the auxiliary agent of 0.1% of slurry dry weight, in At a temperature of 105°C, react for 60 minutes. The bamboo pulp used in this example is self-made, the kappa number of the raw pulp is 21.7, the viscosity of the slurry is 1184ml / g, and the whiteness of the slurry is 27.4%ISO.

[0028] The relevant measurement results are as follows...

Embodiment 2

[0030] Weigh 15kg sodium dodecylbenzenesulfonate, 20kg sodium lignosulfonate, 20kg anthraquinone derivatives, 30kg sodium sulfite, and 15kg sodium tripolyphosphate. Mix the above components uniformly at room temperature for no less than 30 minutes to form the oxygen bleaching aid.

[0031] Take unbleached bamboo pulp with a pulp concentration of 12%, feed it with oxygen at an oxygen pressure of 0.5MPa, add NaOH so that the quality of NaOH accounts for 2.0% of the dry weight of the pulp, and add 0.7% of the auxiliary agent of the dry weight of the pulp , at a temperature of 95°C, react for 60min. The bamboo pulp used in this example is self-made, the kappa number of the raw pulp is 21.7, the viscosity of the slurry is 1184ml / g, and the whiteness of the slurry is 27.4%ISO.

[0032] The relevant measurement results are as follows: Kappa value 9.68, pulp viscosity 1063ml / g, pulp whiteness 45.2%ISO, viscosity reduction rate 10.2%, lignin removal rate 55.4%.

Embodiment 3

[0034] Weigh 10kg of sodium dodecylbenzenesulfonate, 15kg of sodium lignosulfonate, 10kg of anthraquinone derivatives, 55kg of sodium sulfite, and 10kg of sodium tripolyphosphate. Among them, the manufacturer of anthraquinone derivatives is Chongqing Leapfrog (Group) Hunan Xiangyu Chemical Co., Ltd., a subsidiary of the company. Mix the above components uniformly at room temperature for no less than 30 minutes to form the oxygen bleaching aid. When in use, weigh the oxygen bleaching aid according to the percentage of the dry weight of the slurry, dissolve the weighed oxygen bleaching aid in the oxygen bleaching alkaline solution, and pump it into the slurry together to complete the addition of the aid.

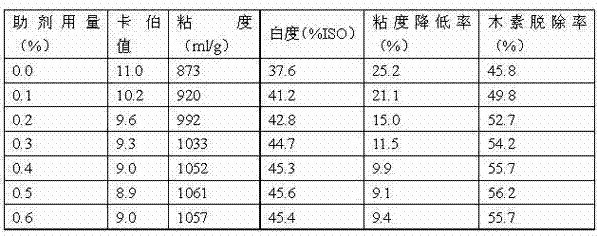

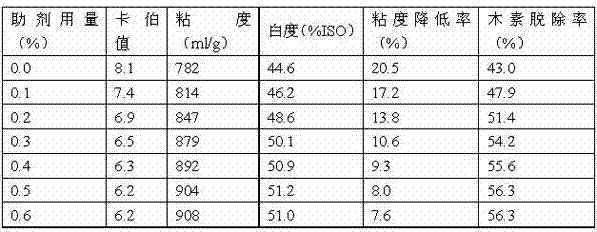

[0035] The auxiliary agent prepared by different consumption embodiment 3 is used for the oxygen delignification of bamboo pulp:

[0036] The unbleached bamboo pulp used in this experiment was taken from Sichuan Yongfeng Pulp and Paper Co., Ltd., the kappa number of the raw p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com