Preparation method for pyroelectric thick film detector with silicon cup groove structure

A technology for structural heat and detectors, applied in electrical radiation detectors, thermoelectric devices with thermal changes in dielectric constant, etc. Infrared performance, easy operation, and the effect of protecting integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

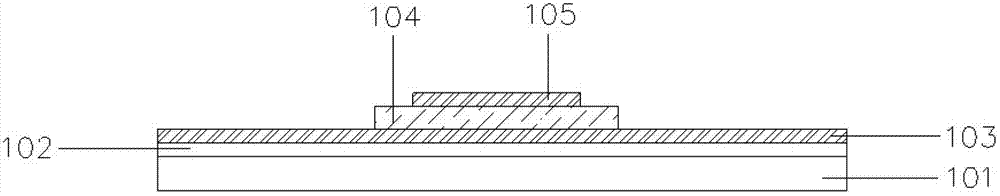

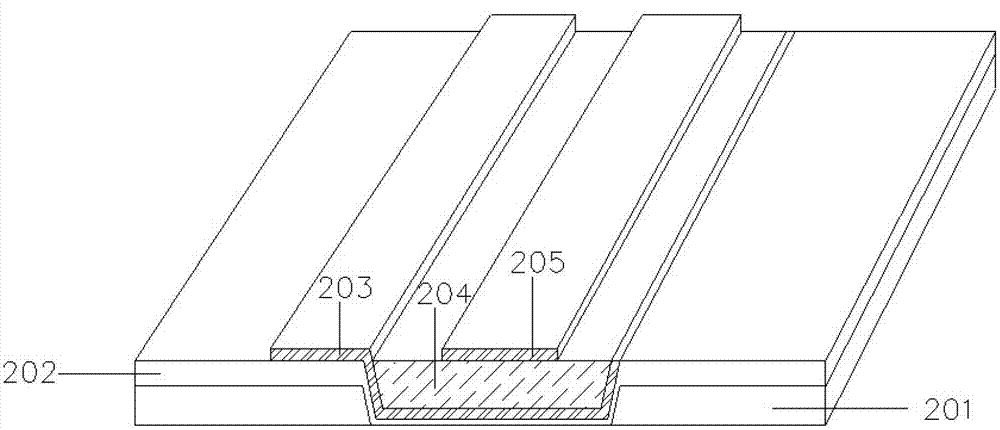

[0038]In order to solve the problems of poor performance of thick film materials in pyroelectric thick film detectors, high sintering temperature and easy cracking of thick film materials, the purpose of the present invention is to provide a new pyroelectric thick film detector and its preparation method. The present invention is based on the micro-mechanical process, and adopts a through-silicon via interconnection manufacturing technology to prepare a groove structure with a certain slope and depth in the substrate. After preparing the barrier layer and the bottom electrode in the groove, deposit the pyroelectric thick film material, so that it just fills the entire groove, the surface of the thick film material is exactly the same height as the substrate surface, then the thick film is isostatically pressed, sintered into porcelain at high temperature, and finally the upper layer is drawn out by photolithography and sputtering. electrode. In order to ensure the smooth extra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com