Integrated honeycomb SCR (selective catalytic reduction) catalyst for low-temperature smoke denitration and preparation method of catalyst

A honeycomb catalyst and low-temperature flue gas technology, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of reduced catalytic activity, no investigation, activity discount, etc., and achieve good low-temperature activity and water resistance The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

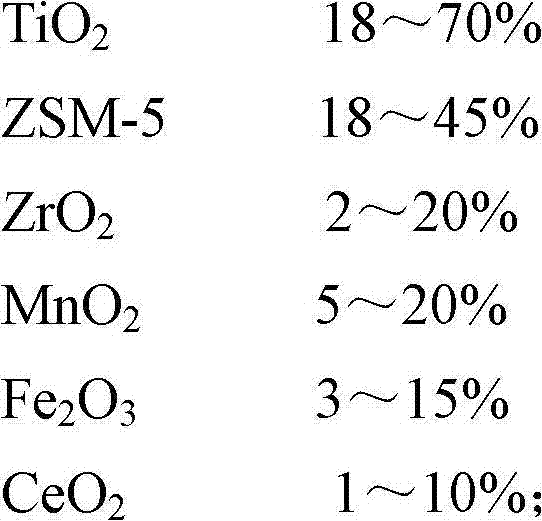

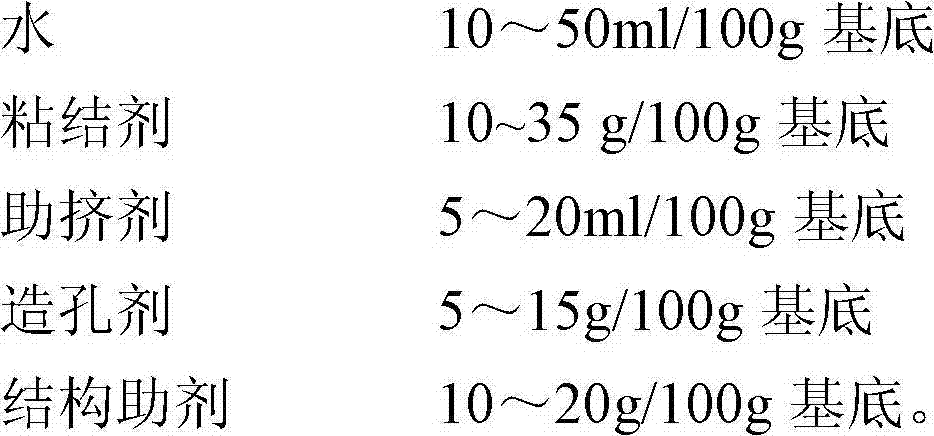

[0043] 1. Preparation of monolithic honeycomb catalyst for SCR flue gas denitrification

[0044] (1) Dry mix. Take 640gTiO 2 Powder, 225gFeC 2 o4 2H 2 O, 338gMn(CH 3 COO) 2 4H 2 O, 76gCe(NO 3 ) 3 ·6H 2 O, 384gZr(NO 3 ) 4 ·5H 2 O. 96g glass fiber, 64g carboxymethyl cellulose, 64g pseudo-boehmite, 32g activated carbon, put various solids together in a dry powder mixer and mix for 15 minutes.

[0045] (2) Kneading. 128ml of water and 128ml of glycerin were added to the above mixed material, and the kneading process was started for 30 minutes.

[0046] (3) Practicing mud. Pass the kneaded plastic material through a sieve plate or transfer it to a vacuum mud mixer to remove excess water and gas in the material.

[0047] (4) extrusion molding. The dense and uniform mud segment obtained after mud refining enters the extruder, and is extruded through a honeycomb steel die to obtain a catalyst green body.

[0048] (5) drying and roasting. Dry at 60°C for 10 hours, rai...

Embodiment 2

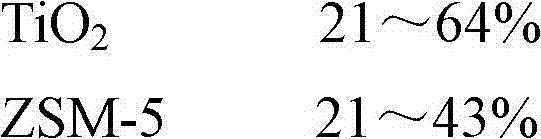

[0054] 1. Preparation of monolithic honeycomb catalyst for SCR flue gas denitrification

[0055] (1) Dry mix. Take 210gTiO 2 Powder, 430gZSM-5 (Si / Al=347), 180gFeC 2 o 4 2H 2 O, 394gMn(CH 3 COO) 2 4H 2 O, 76gCe(NO 3 ) 3 ·6H 2 O, 384gZr(NO 3 ) 4 ·5H 2 O, 96g glass fiber, 64g sodium carboxymethyl cellulose, 64g pseudo-boehmite, 64g gac. Put various solids together in a dry powder mixer and mix for 15 minutes.

[0056] (2) Kneading. 96ml of water and 128ml of glycerin were added to the above mixed material, and the kneading process was started for 20 minutes.

[0057] (3) Practicing mud. Pass the kneaded plastic material through a sieve plate or transfer it to a vacuum mud mixer to remove excess water and gas in the material.

[0058] (4) extrusion molding. The dense and uniform mud segment obtained after mud refining enters the extruder, and is extruded through a honeycomb steel die to obtain a catalyst green body.

Embodiment 3

[0065] 1. Preparation of monolithic honeycomb catalyst for SCR flue gas denitrification

[0066] (1) Dry mix. Take 430g TiO 2 Powder, 210g ZSM-5 (Si / Al=347), 225gFeC 2 o 4 2H 2 O, 338gMn(CH 3 COO) 2 4H 2 O, 76gCe(NO 3 ) 3 ·6H 2 O, 384gZr(NO 3 ) 4 ·5H 2 O, 64g glass fiber, 64g sodium carboxymethyl cellulose, 64g pseudo-boehmite, 64g gac. Put various solids together in a dry powder mixer and mix for 15 minutes.

[0067] (2) Kneading. 160ml of water and 128ml of glycerin were added to the above mixture, and the kneading process was started for 30 minutes.

[0068] (3) Practicing mud. Pass the kneaded plastic material through a sieve plate or transfer it to a vacuum mud mixer to remove excess water and gas in the material.

[0069] (4) extrusion molding. The dense and uniform mud segment obtained after mud refining enters the extruder, and is extruded through a honeycomb steel die to obtain a catalyst green body.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com