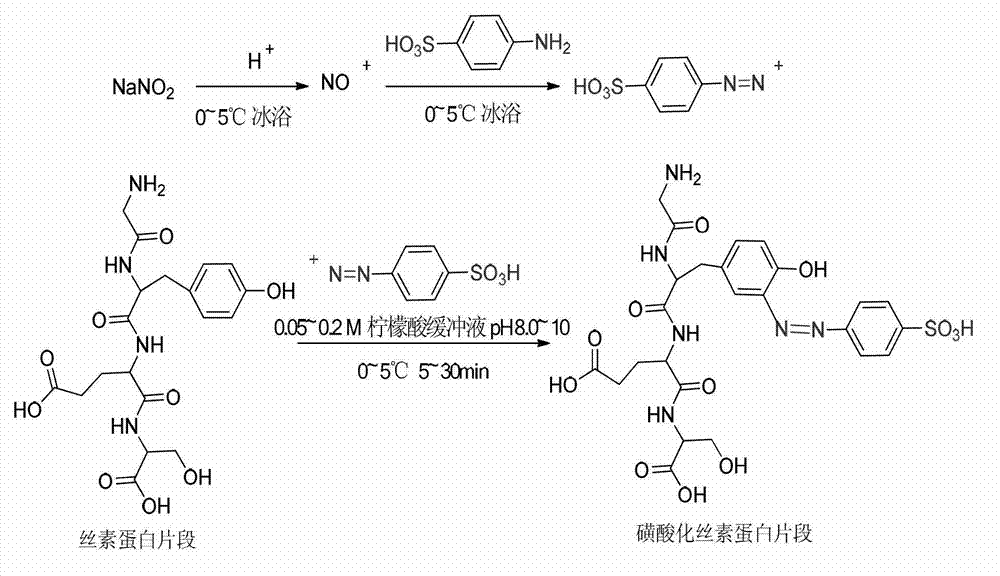

Preparation method of sulfated silk fibroin material

A technology of sulfonated silk fibroin and silk fibroin, which is applied in the field of preparation of sulfonated silk fibroin materials, can solve the problems of low biological activity, low biological activity, small immunogenicity, etc., and achieve high reaction efficiency and good resistance Effect of coagulation and improvement of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Mix 2mL of 0.4M aqueous solution of p-aminobenzenesulfonic acid with 1mL of 1.6M aqueous solution of p-toluenesulfonic acid, the molar ratio of p-aminobenzenesulfonic acid to p-toluenesulfonic acid is 1:2, and keep the temperature at 5°C.

[0019] Add 1mL of 0.8M sodium nitrite aqueous solution in ice bath to the mixed liquid in step 1, mix well, and maintain the ice bath for 15 min to obtain the azo salt reaction liquid.

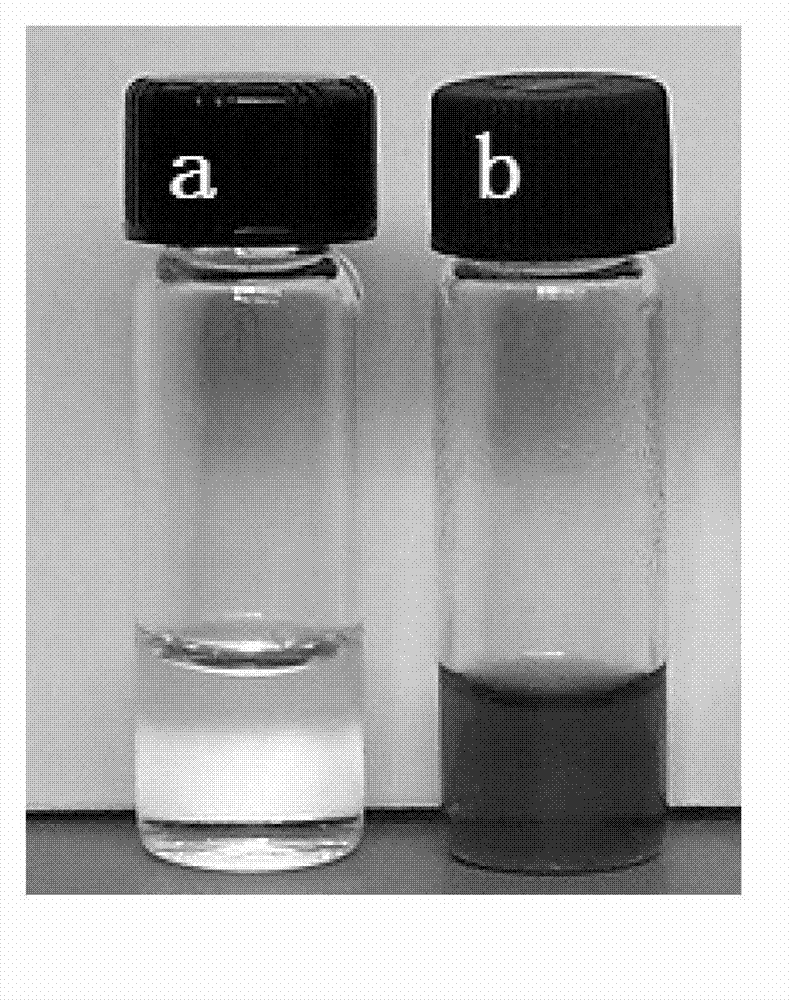

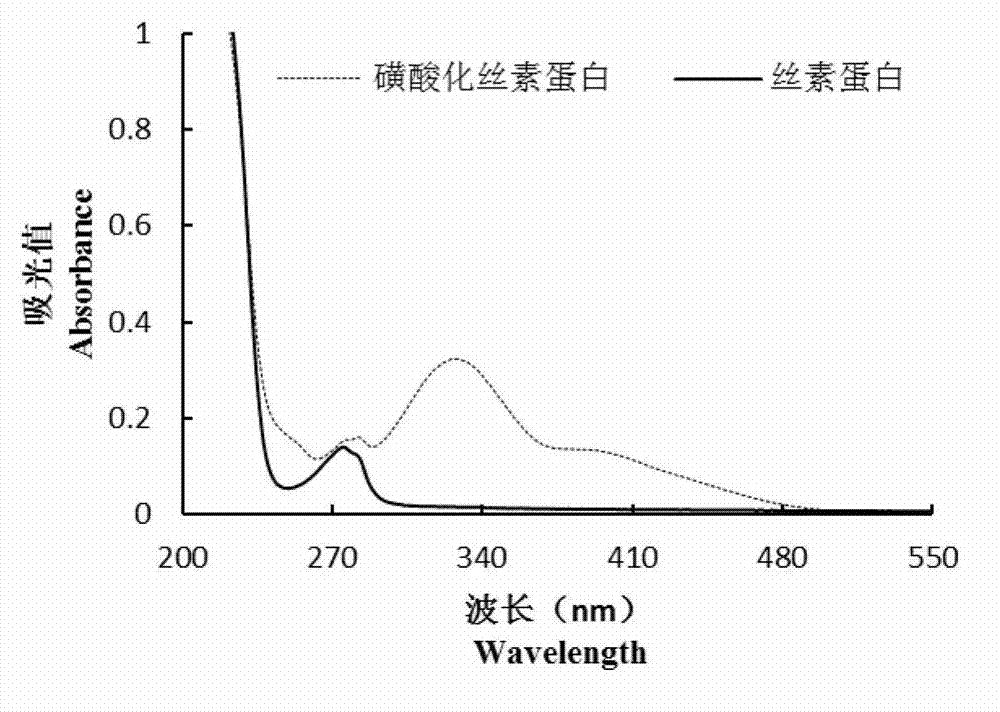

[0020] Dissolve 0.8g silk fibroin in citrate buffer solution (0.05M pH 8) to obtain 8mL silk fibroin solution with a concentration of 10% (w / v, g / mL), add 16mL azo salt reaction solution (2mL / 100mg silk fibroin), maintain the pH at 8 with citric acid buffer, react in an ice bath for 20 minutes, use a dialysis bag with a molecular weight cut-off of 3500 for 2-3 days, and freeze-dry to obtain sulfonated silk fibroin.

Embodiment 2

[0022] Mix 10mL 0.08M p-toluenesulfonic acid aqueous solution with 4mL 1.6M p-toluenesulfonic acid aqueous solution, the molar ratio of p-aminobenzenesulfonic acid to p-toluenesulfonic acid is 1:8, and keep the temperature at 0°C.

[0023] Add 1.6mL of 1M sodium nitrite aqueous solution in ice bath to the mixed liquid in step 1, mix well, and maintain the ice bath for 30min to obtain the azo salt reaction liquid.

[0024] Dissolve 0.8g of silk fibroin in citrate buffer solution (0.05M pH 8) to obtain 4mL of silk fibroin solution with a concentration of 20% (w / v, g / mL), add 0.08mL of azo salt to react solution (0.01mL / 100mg silk fibroin), maintain the pH at 10 with citric acid buffer, react in an ice bath for 15 minutes, use a dialysis bag with a molecular weight cut-off of 3500 for 2-3 days, and freeze-dry to obtain sulfonated silk fibroin.

Embodiment 3

[0026] Mix 100mL of 1mM p-toluenesulfonic acid aqueous solution with 40mL of 0.01M p-toluenesulfonic acid aqueous solution and cool in an ice bath.

[0027] Add 0.0017mL of 6M sodium nitrite aqueous solution in ice bath to the mixture in step 1, mix well, and maintain the ice bath for 20min to obtain the azo salt reaction liquid.

[0028] Dissolve 0.1g silk fibroin in citrate buffer solution (0.05M pH 8) to obtain 10mL silk fibroin solution with a concentration of 1% (w / v, g / mL), add 1mL azo salt reaction solution (1 mL / 100 mg silk fibroin), maintain the pH at 9 with citric acid buffer, react in an ice bath for 10 min, dialyze for 2-3 days with a dialysis bag with a molecular weight cut-off of 3500, and freeze-dry to obtain sulfonated silk fibroin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com