Nano-scale insulation board and manufacturing method thereof

A production method and nano-scale technology, which are applied in insulation improvement, manufacturing tools, building components, etc., can solve the problems of poor fire resistance and thermal insulation performance of thermal insulation materials, easy cracking of thermal insulation materials, etc., and achieve good shading performance and convenience. Construction, the effect of increasing the thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

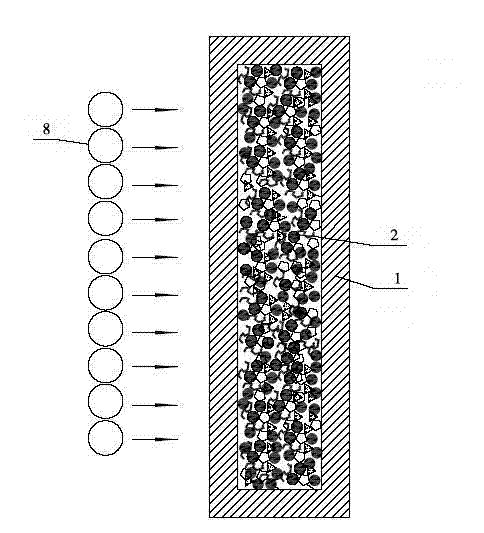

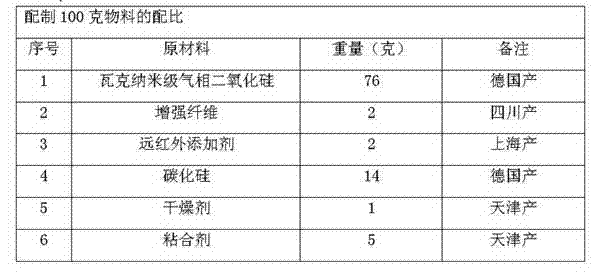

[0042] Embodiment one sees figure 1 As shown, this nano-scale thermal insulation board is characterized in that its board body is made of thermal insulation material packed in a packaging bag and vacuum-sealed. The ratio of the raw materials of the thermal insulation material calculated by weight is as follows:

[0043] Wacker nano-scale fumed silica: 70% to 80%;

[0044] Reinforced fiber: 1% to 3%;

[0045] Far-infrared additives: 1% to 3%;

[0046] Silicon carbide: 12% to 18%;

[0047] Desiccant: 0.8%~1.2%;

[0048] Adhesive: 5%~10%;

[0049] Technical parameters of the board: thermal conductivity 0.0026 W / (m K), mass per unit area (surface density) 4.5±0.4kg / m 2 . The size and thickness of the product can be determined according to the needs of the construction site, for example, 300mm×300mm×15mm can be used, and the thickness can be selected from 10mm to 100mm.

[0050] The thermal insulation material (2) can be wrapped in a non-woven fabric (7) first, and then pack...

Embodiment 2

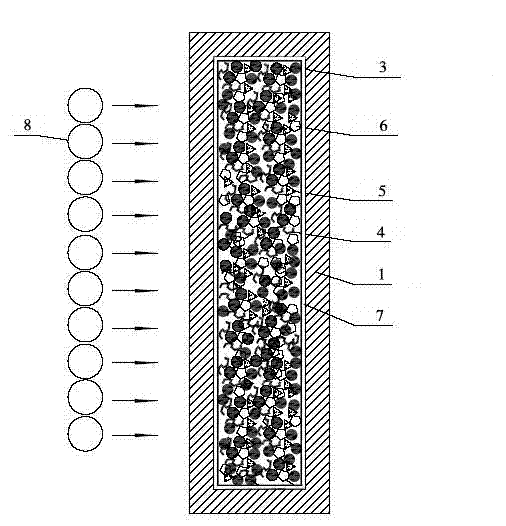

[0066] Embodiment two see figure 2 , it is made of non-woven fabric wrapped with thermal insulation material and vacuum-sealed in a packaging bag. After putting in the thermal insulation material, the non-woven fabric is folded and ironed. The non-woven fabric can be processed by the manufacturer, and the size is determined by the size of the pallet. The production speed of the product is fast, the dust is less, and the operation is convenient. In the fourth production step, the non-woven fabric can be laid in the pallet mold, the material is put into the middle pallet mold, the platen pressing machine is started to form the thermal insulation material into a plate shape, and then the non-woven fabric is wrapped and sealed and ironed. ; After the fifth step, the excess powder on the pallet mold can be swept away, and the dust collection method is adopted, and collected into the storage tank for recycling.

Embodiment 3

[0068]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com