A kind of patterned electrode, preparation method and organic solar cell

A solar cell and patterning technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems that organic solar cells cannot be prepared in a large area, the preparation process is complicated, and the cost is expensive.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

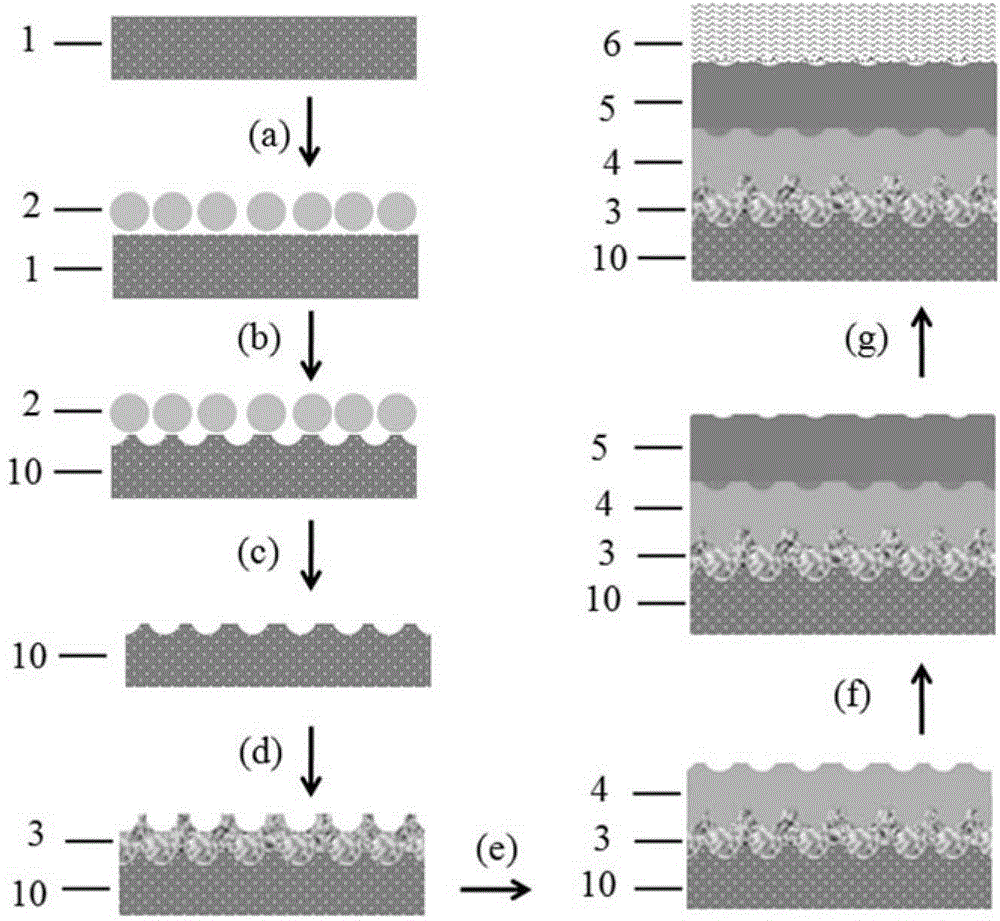

[0068]The ITO electrode 1 is ultrasonically cleaned with detergent plus deionized water and acetone in sequence, and then the ITO electrode 1 is treated with ultraviolet light. Then if Figure 4 As shown, perform the following steps:

[0069] (a) On the ITO electrode 1, PS nanospheres with a size of 100 nm are prepared as a nanostructure layer 2 (such as Figure 5 as shown in a);

[0070] (b) Using PS nanospheres as a template, corrode the ITO electrode 1 with hydrochloric acid, and rinse off the residual hydrochloric acid on the electrodes and nanospheres with deionized water after 2.5 minutes of corrosion;

[0071] (c) Remove the PS nanospheres with ultrasound in chloroform, then ultrasonically clean them in isopropanol for 15 minutes, and dry them with nitrogen to obtain a patterned ITO electrode 10 (such as Figure 5 as mentioned in b);

[0072] (d) Prepare 10nm thick MoO on the patterned ITO electrode 10 by thermal evaporation method 3 As the anode buffer layer as th...

Embodiment 2

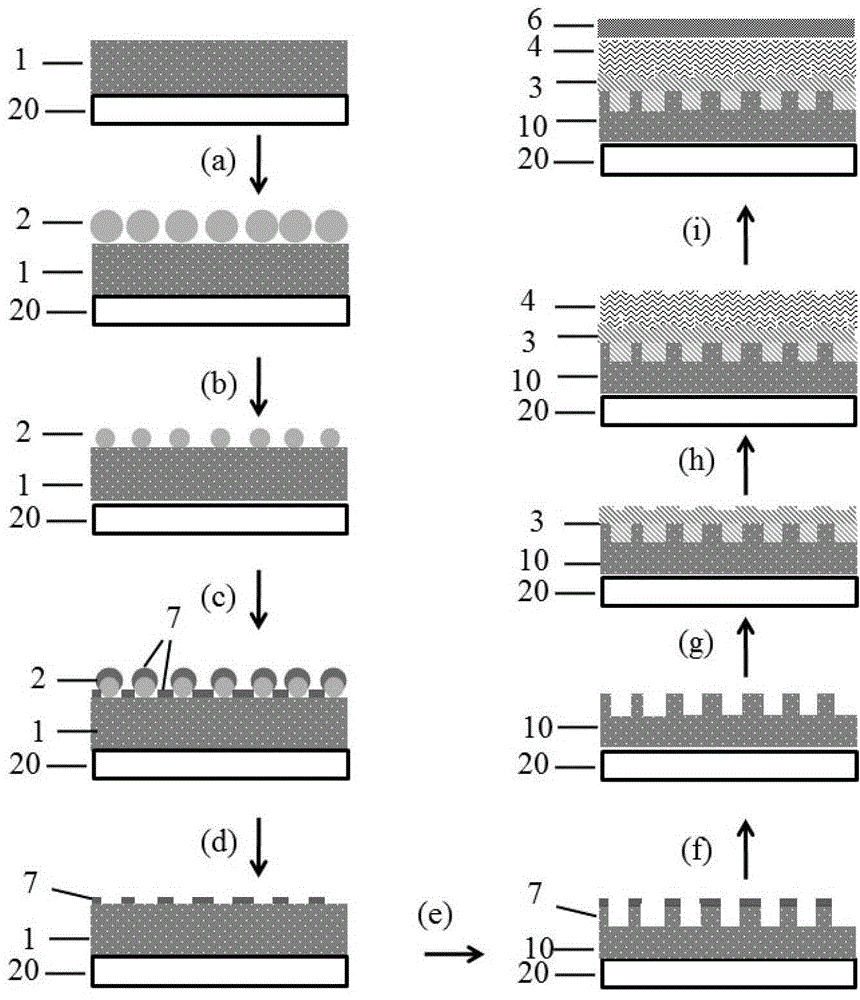

[0080] The ITO electrode 1 is ultrasonically cleaned with detergent plus deionized water and acetone in sequence, and then the ITO electrode 1 is treated with ultraviolet light. Then carry out the following steps to prepare the patterned electrode 10:

[0081] (a) Spin-coating method (2500rpm, 30s) on the ITO electrode 1 to prepare SiO with a size of 200nm 2 Nanospheres as nanostructures 2;

[0082] (b) Due to the conditions of (a), SiO prepared on ITO 2 Nanospheres are not SiO forming close contacts 2 Nanosphere layer, but there is a larger gap between the nanosphere and the nanosphere, so it is not necessary to reduce the size of the nanosphere ( figure 2 In (b) step), it can be prepared in SiO 2 After the nanospheres, the SiO 2 Nanospheres are used as templates to prepare metal thin film layers;

[0083] (c) Using magnetron sputtering method to SiO 2 The nanosphere is used as a template to prepare a Cr layer with a thickness of 150 nm on the ITO electrode 1 as the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com