Method for improving efficiency of copper-zinc-tin-sulfur-selenium solar cells by using CuAlO2 transition layer

A copper-zinc-tin-sulfur-selenium, solar cell technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as side effects, and achieve the effects of improving crystal quality, simple preparation process, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

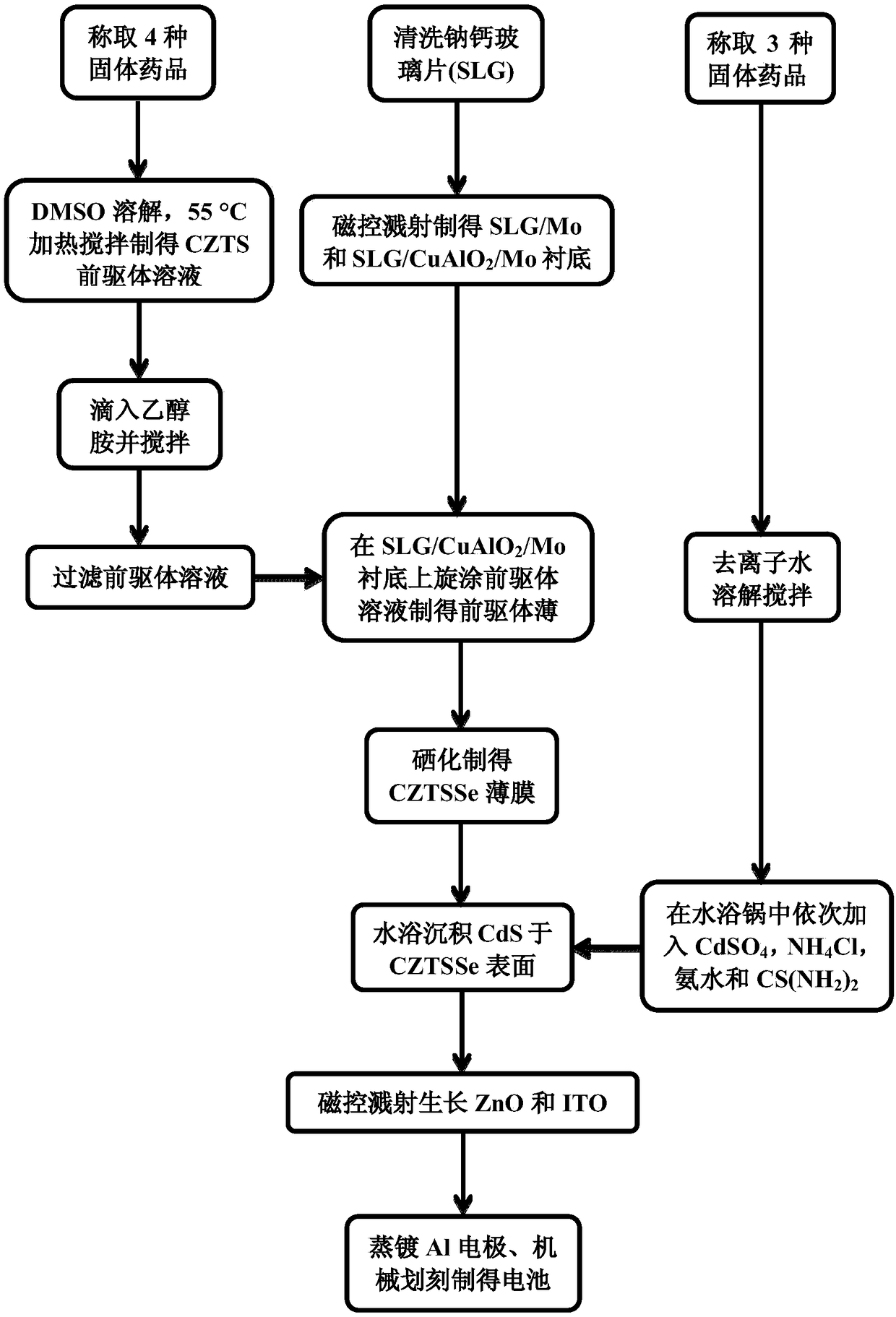

Method used

Image

Examples

Embodiment 1

[0035] The present invention uses CuO (99.99%, 200 mesh) powder and Al 2 o 3 (99.999%, 5μm) powder as raw material, CuO and Al were prepared according to the atomic ratio of Cu:Al:O=1:1:2 2 o 3 The mixed powder is fully ground and pressed under a pressure of 52MPa to form a target body with a height of 3mm and a diameter of 70mm, and then put it into a high-temperature box furnace for calcination at 1200°C for 10h, and finally cool down at a rate of 5°C / min to 600°C, and then naturally lowered to room temperature to make a CAO target. Using the prepared CAO target material, high-purity Ar (99.999%) as the sputtering gas, under the conditions of working pressure of 1.0Pa, sputtering power of 40W, and substrate temperature of room temperature, it was grown on the SLG / Mo substrate The CAO amorphous film can regulate the thickness of the CAO film by controlling the growth time.

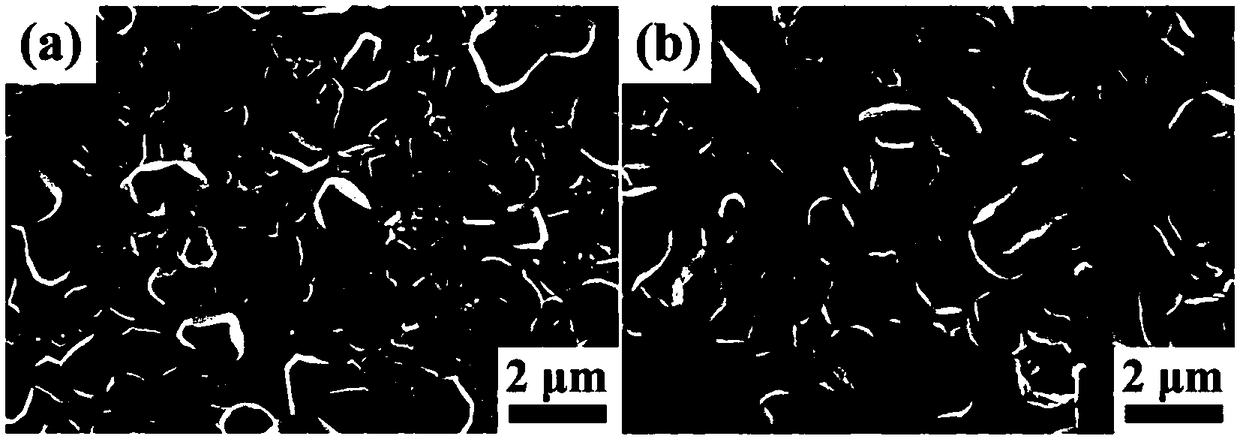

[0036] CZTSSe solar cells were prepared on SLG / Mo and SLG / Mo / CAO substrates respectively, where th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com