Antireflection coated glass with self-cleaning effect and preparation method thereof

A coated glass and self-cleaning technology, which is applied in the field of anti-reflection coated glass and its preparation, can solve the problems of double-layer coating and no self-cleaning effect of packaging glass for solar cells that have not yet been found, and achieve low raw material and manufacturing costs and low production costs. high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method in the embodiment comprises:

[0039] Step 1: cutting, edging, cleaning and drying the fresh ultra-clear embossed glass original sheet with a thickness of 3.2 ~ 6.0 mm;

[0040] Step 2, uniformly coating the high-refractive index composite sol on the suede surface of the ultra-clear embossed glass by using a roll coating coating process;

[0041] Step 3: Under the environmental conditions of temperature 25°C and relative humidity 40%, surface drying treatment for 30-60s, and pre-curing treatment at temperature 160°C for 180s to obtain a high refractive index film precursor;

[0042] Step 4, uniformly coating the self-cleaning composite sol on the high refractive index film layer precursor by spray coating or flow coating process;

[0043] Step 5: Under the environmental conditions of temperature 25°C and relative humidity 40%, surface drying treatment for 30-60s, and pre-curing treatment at temperature 160°C for 180s to obtain the precursor of th...

Embodiment 1

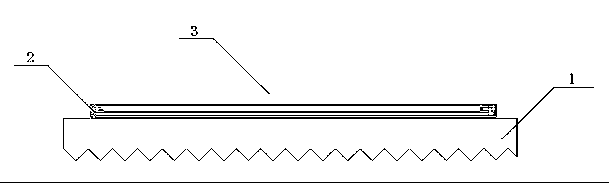

[0048] like figure 1 As shown, a self-cleaning anti-reflection coated glass is composed of an ultra-clear glass substrate 1, and a high-refractive-index film layer 2 is applied on the ultra-clear glass substrate, and the high-refractive-index film layer The top is coated with a self-cleaning functional film layer 3, wherein:

[0049] The ultra-clear glass substrate 1 is ultra-clear embossed glass with a thickness of 3.2mm and a transmittance of 91.4%;

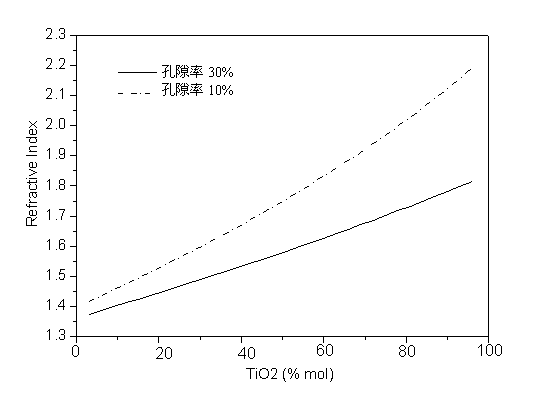

[0050] The high refractive index film layer is made of nano silicon oxide SiO 2 Granular and Nano Zirconia ZrO 2 Particle composition, the porosity of the film layer is less than 10%, the refractive index of the film layer is about 1.81, and the film thickness is about 75nm;

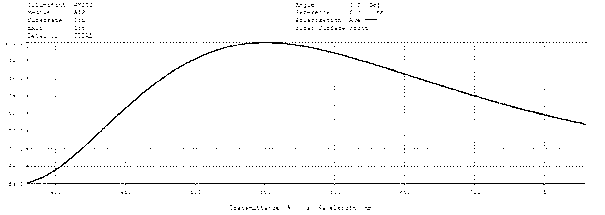

[0051] The self-cleaning functional film layer is made of nano silicon oxide SiO 2 Granular and Nano Titanium Oxide TiO 2 Particle composition, the particle diameter is about 20~60, the porosity of the film layer is about 30%, of which TiO 2 : SiO ...

Embodiment 2

[0062] A kind of antireflection coated glass with self-cleaning effect, its structure is identical with embodiment 1, wherein:

[0063] The ultra-clear glass substrate 1 is ultra-clear float glass with a thickness of 3.2m and a transmittance of 91.4%;

[0064] The composition, porosity, refractive index and thickness of the high refractive index film layer are all the same as or very close to those of the examples;

[0065] Composition, particle size, porosity, and TiO in the self-cleaning functional film layer 2 : SiO 2 The content ratio, refractive index, and thickness are the same as in Example 1.

[0066] Prepare as follows:

[0067] Step 1: cutting, edging, cleaning and drying the original ultra-clear float glass;

[0068] Step 2, uniformly coating the high-refractive index composite sol on the non-tin surface of the ultra-clear float glass by using a roll coating coating process;

[0069] Steps three to six are the same as in Example 1.

[0070] Among them, the hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com