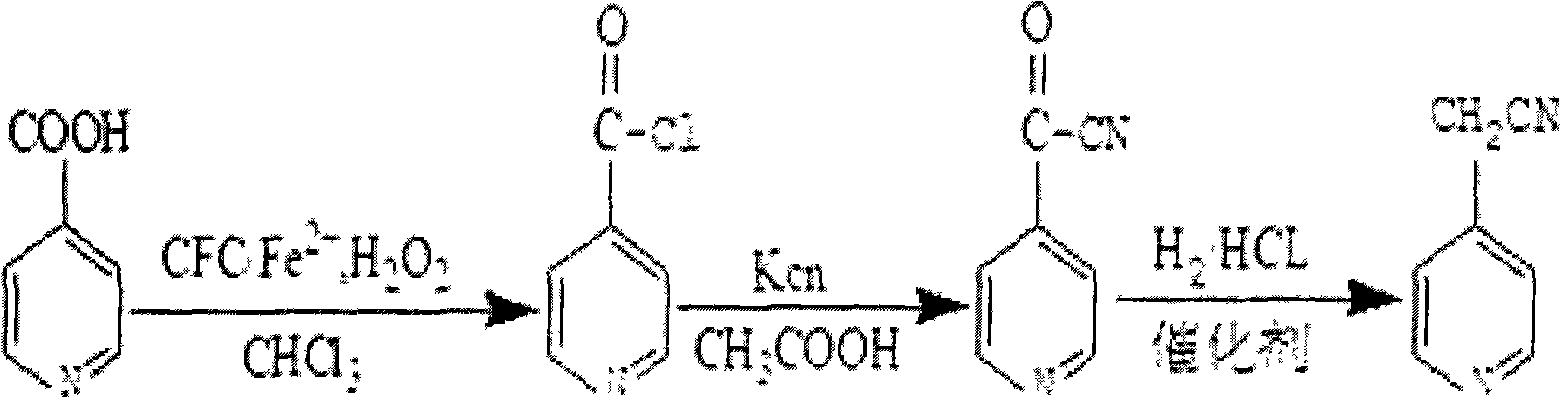

Synthesis method of pyridylacetonitrile

A technology of pyridineacetonitrile and synthesis method, applied in directions such as organic chemistry, can solve problems such as complicated post-processing, expensive raw materials, etc., and achieve the effects of stable operation and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0020] 2-pyridinecarboxylic acid 3.62g (0.58mol) difluorodichloromethane (CFC-12) 3.62g (0.58mol) methyl

[0021] Iodine 3.62g (0.58mol) Hydrogen oxide solution 162.3g (1.45mol)

[0022] Ferrous chloride 162.3g (1.45mol)

[0023] Its synthetic method is:

[0024] Add 2-pyridinecarboxylic acid, difluorodichloromethane (CFC-12), and methyl iodide into a 520ml three-necked flask, dissolve in 200ml chloroform, add hydrogen peroxide solution and chlorination solution dropwise under ice-water cooling For ferrous ferrous, keep the temperature of the reaction solution not exceeding 7°C, gradually raise it to 28°C after the dropwise addition, stir for 2 hours, heat up and reflux for about 3 hours, and precipitate the solid by suction filtration, and the solid obtained after the filtrate recovers the solvent is combined into a product, and the solid product is Freely obtain picolinoyl chloride; then dissolve picolinoyl chloride in 483ml, 65% acid ester solution, add potassium cyanide,...

example 2

[0026] 3-pyridinecarboxylic acid 2.82g (0.36mol) a fluorotrichloromethane (CFC-11) 2.93g (0.45mol) methyl

[0027] Bromine 3.62g (0.58mol) Hydrogen oxide solution 169.3g (1.49mol)

[0028] Ferrous chloride 162.3g (1.45mol)

[0029] Its synthetic method is:

[0030] Add 3-pyridinecarboxylic acid, fluorotrichloromethane (CFC-11), and methyl bromide into a 520ml three-necked flask, dissolve in 200ml of chloroform, add hydrogen peroxide solution and chlorinated For ferrous ferrous, keep the temperature of the reaction solution not exceeding 7°C, gradually raise it to 25°C after the dropwise addition, stir for 2 hours, heat up and reflux for about 2.5 hours, and precipitate the solid by suction filtration, and the solid obtained after the filtrate recovers the solvent is combined into a product, and the solid Free the product to obtain picolinoyl chloride; then dissolve picolinoyl chloride in 483ml, 65% acid ester solution, add potassium cyanide, heat to 81°C, and reflux for 1h. ...

example 3

[0032] 4-pyridinecarboxylic acid 3.62g (0.58mol) methyl chloride 3.62g (0.58mol)

[0033] Methyl Bromide 4.08g (0.69mol) Hydrogen Oxide Solution 165.7g (1.51mol)

[0034] Ferrous chloride 162.3g (1.45mol)

[0035] Its synthetic method is:

[0036] Add 4-pyridinecarboxylic acid, methyl chloride, and methyl bromide into a 496ml three-necked flask, dissolve in 200ml of chloroform, add hydrogen peroxide solution and ferrous chloride dropwise under ice water cooling, and keep the temperature of the reaction solution Not more than 7°C, gradually raised to 25°C after the dropwise addition, stirred for 2 hours, heated and refluxed for about 2.5 hours, the solid was precipitated by suction filtration, and the solid obtained after the filtrate recovered the solvent was combined into a product, and the solid product was freed to obtain picolinoyl chloride; Then dissolve picolinoyl chloride in 483ml, 65% acid vinegar solution, add potassium cyanide, heat to 81°C, and reflux for 1h. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com