Preparation method of Levamlodipine besylate tablet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

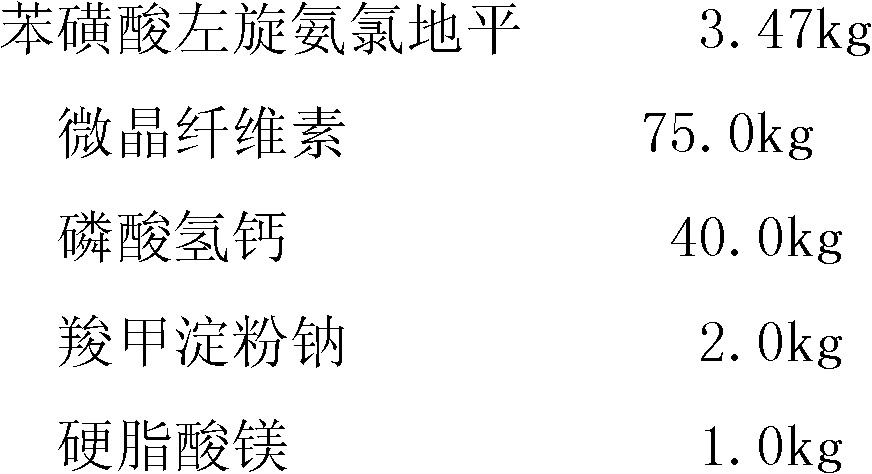

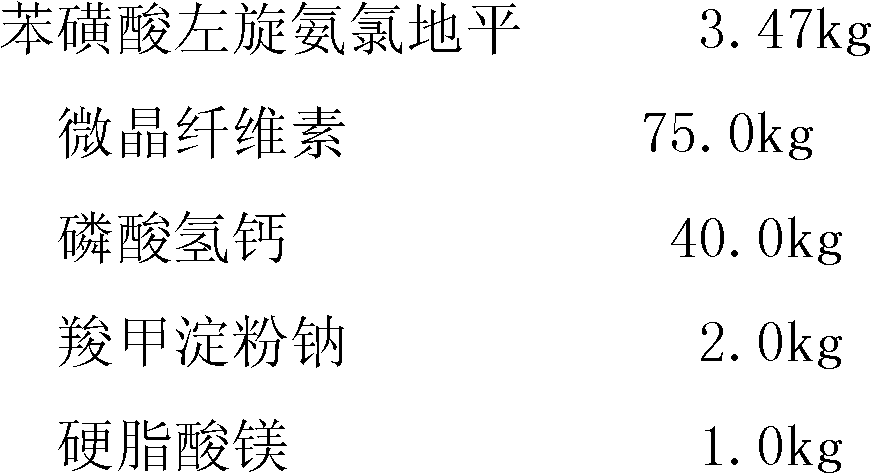

[0021] (1) Formula: (calculated on the basis of 1,000,000 plain tablets)

[0022]

[0023] The filler is: microcrystalline cellulose, calcium hydrogen phosphate

[0024] The disintegrant is sodium carboxymethyl starch, the lubricant is magnesium stearate

[0025] The above raw and auxiliary materials are all sold in the market.

[0026] (2) method:

[0027] Firstly, levamlodipine besylate and calcium hydrogen phosphate are pulverized through a 100-mesh sieve, microcrystalline cellulose and carboxymethyl starch sodium are pulverized through a 80-mesh sieve, and then mixed together. Then, mix evenly through a fluidized bed one-step granulator, and the air volume during granulation is 854-964m3 / h; the spray speed is 75rpm; the spray pressure is 1.7bar. Dry, the air volume is 854~964m when dry 3 / h; material temperature 20℃~60℃; set inlet air temperature 40℃~80℃, control moisture 1.5~2.5%. After passing through the 24-mesh sieve, add lubricant and mix evenly in the mixer. ...

Embodiment 2

[0029] The stability of the levamlodipine besylate that embodiment 1 method makes, dissolution rate investigation test:

[0030] 1. Prescription ingredients:

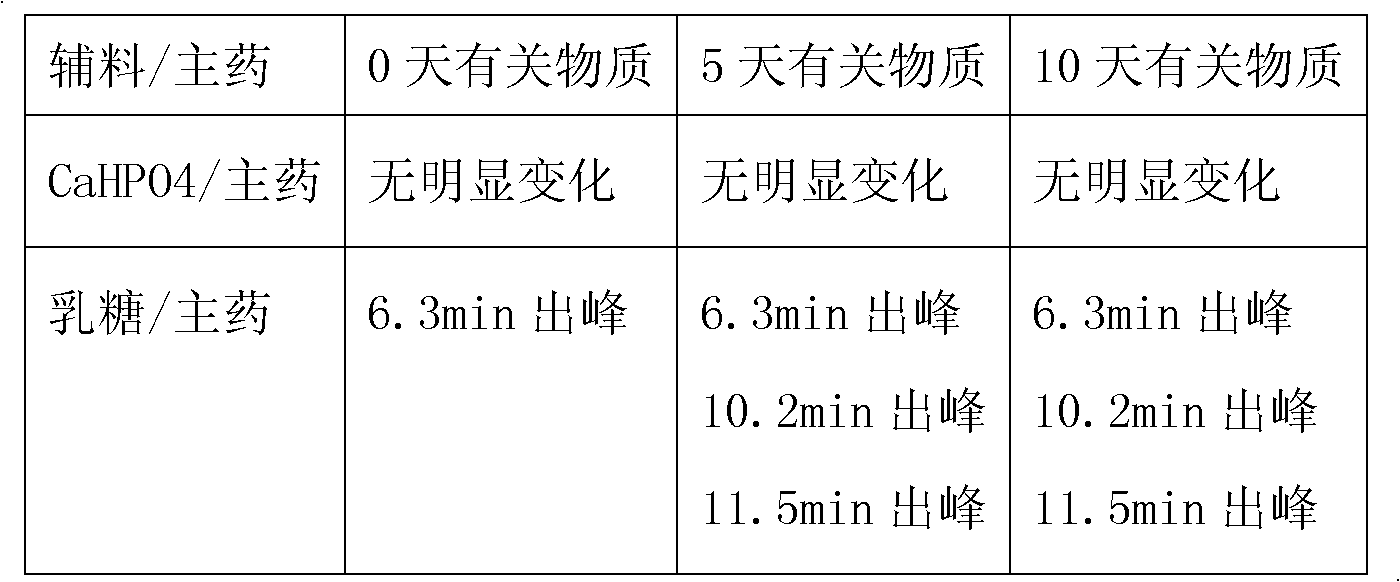

[0031] According to the compatibility test method of excipients, calcium hydrogen phosphate (CaHPO4), lactose and levamlodipine besylate (main drug) were mixed in a ratio of 5:1 respectively, and the prepared samples were respectively placed in an oven at 60° C. 0 day, 5 days, and 10 days to investigate the changes of related substances. To investigate the compatibility of excipients and main ingredients.

[0032] Table 1 Prescription screening test results

[0033]

[0034] The above results show that the application of calcium hydrogen phosphate is more conducive to controlling the amount of related substances in levamlodipine besylate tablets than lactose.

[0035] 2 Stability test results

[0036] (1). Illumination test Take levamlodipine besylate tablets (prepared in Example 1), put them in an open petri dis...

Embodiment 3

[0046] Example 3 The key indicators of the levamlodipine besylate tablets prepared by the method in Example 1 were compared with those of the "Shihuida" product purchased in the market.

[0047] According to the following method, compare the key indicators of commercially available products and self-developed products, that is, related substances, dissolution rate, and content.

[0048] (1) the levamlodipine besylate sheet that embodiment 1 method makes

[0049] 【Related Substances】Keep away from light. Take an appropriate amount of this product’s fine powder (approximately equivalent to levamlodipine 15 mg), accurately weigh it, put it in a 25ml measuring bottle, add an appropriate amount of mobile phase, sonicate to dissolve levamlodipine, let it cool, and dilute to the mark with mobile phase , Shake up, filter, get the continued filtrate as the test solution; precision measure 1ml, put in a 100ml measuring bottle, dilute to the mark with mobile phase, shake up, as the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com