Alkaline earth improving agent prepared by using monosodium glutamate production waste liquid, and preparation method thereof

A technology of waste liquid and improver, applied in chemical instruments and methods, applications, soil conditioning materials, etc., can solve the problem of low nutrient content of biochar, and achieve the effects of sufficient raw materials, neutralizing soil alkalinity, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

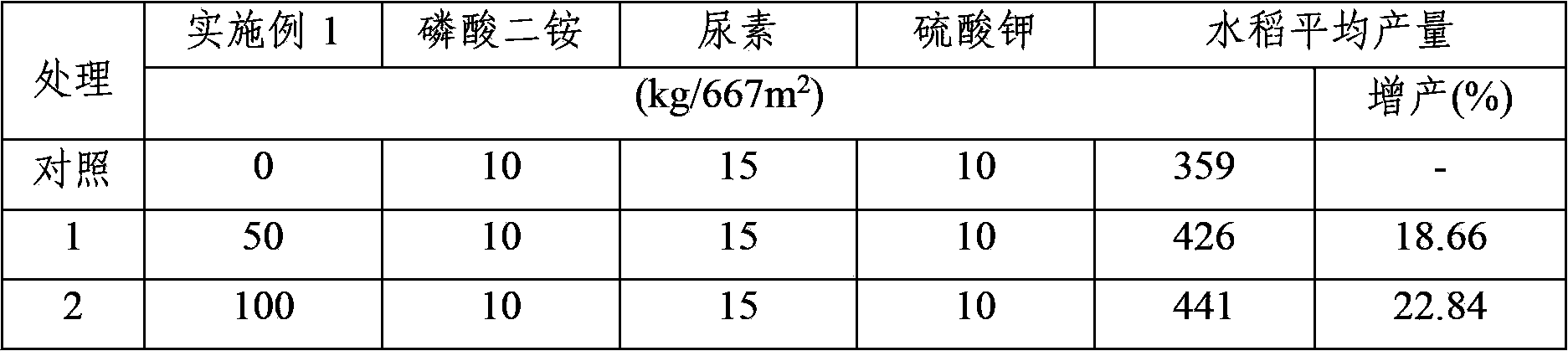

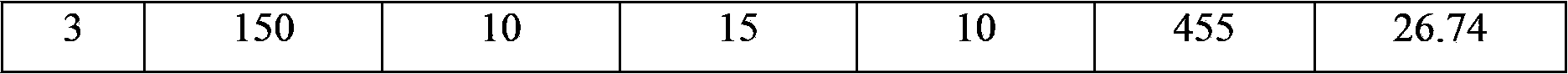

Examples

Embodiment 1

[0028] The composition of the alkaline soil modifier using monosodium glutamate to produce waste liquid is based on the weight ratio of dry matter: 35 parts of monosodium glutamate waste liquid, 25 parts of biochar, 15 parts of lignite, 20 parts of fly ash, and 5 parts of diatomite. Mix the biochar, lignite, fly ash through 50 mesh, and diatomite through 50 mesh according to the ratio, and mix them uniformly by machinery, and add them to the monosodium glutamate with a solid content of 25% by weight after concentration. solution, mixed evenly, the mixture was air-dried to a water content of 10% (weight), passed through a 5-mesh sieve, mixed evenly, and then packaged to obtain an alkaline soil modifier.

Embodiment 2~9

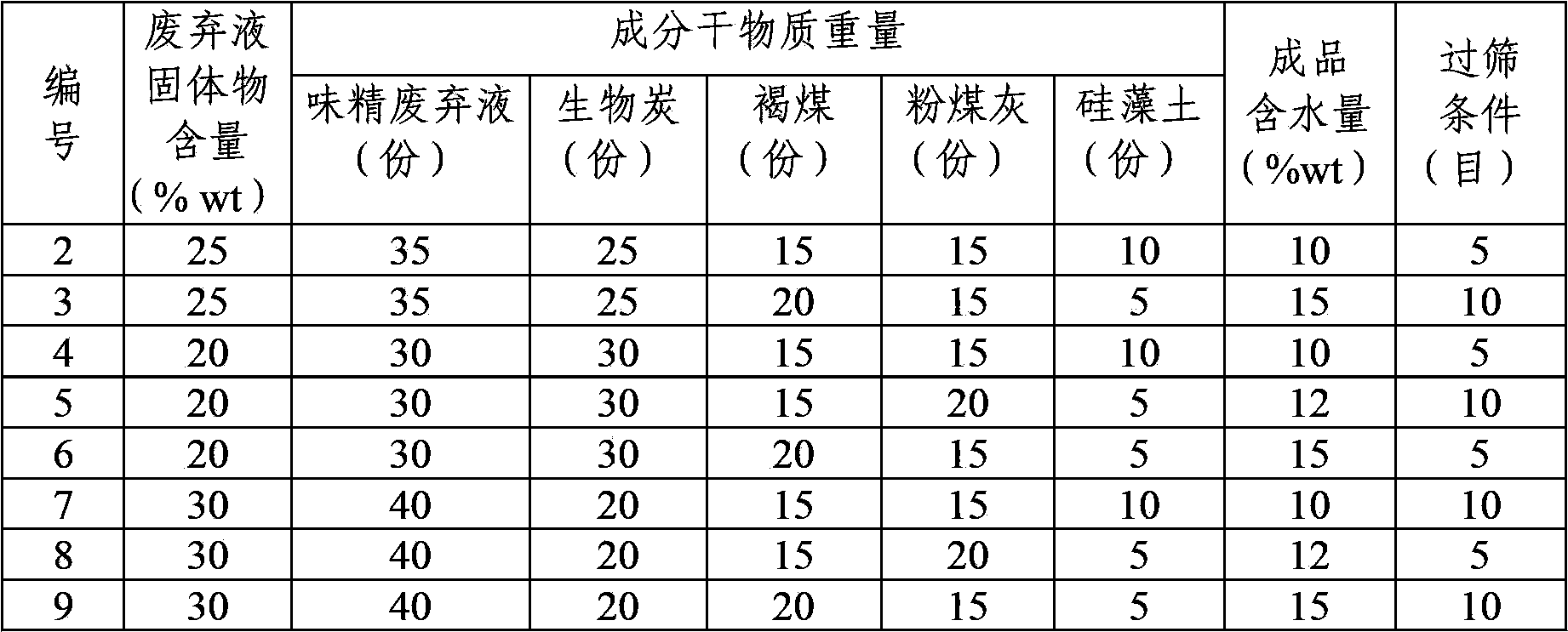

[0030] The difference from Example 1 is that: the ratio of raw materials is different (Table 1), and the specific preparation method is the same as that of Example 1.

[0031] Table 1

[0032]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com