Method for preparing alkane fuels through lignin and application thereof

A technology for lignin and alkane, which is applied in the field of preparing alkane fuel from lignin, can solve the problems of harsh conditions such as temperature and pressure, unfavorable for large-scale industrial production, and high requirements on reaction vessels, and achieves improved reaction conditions, high yield, Simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

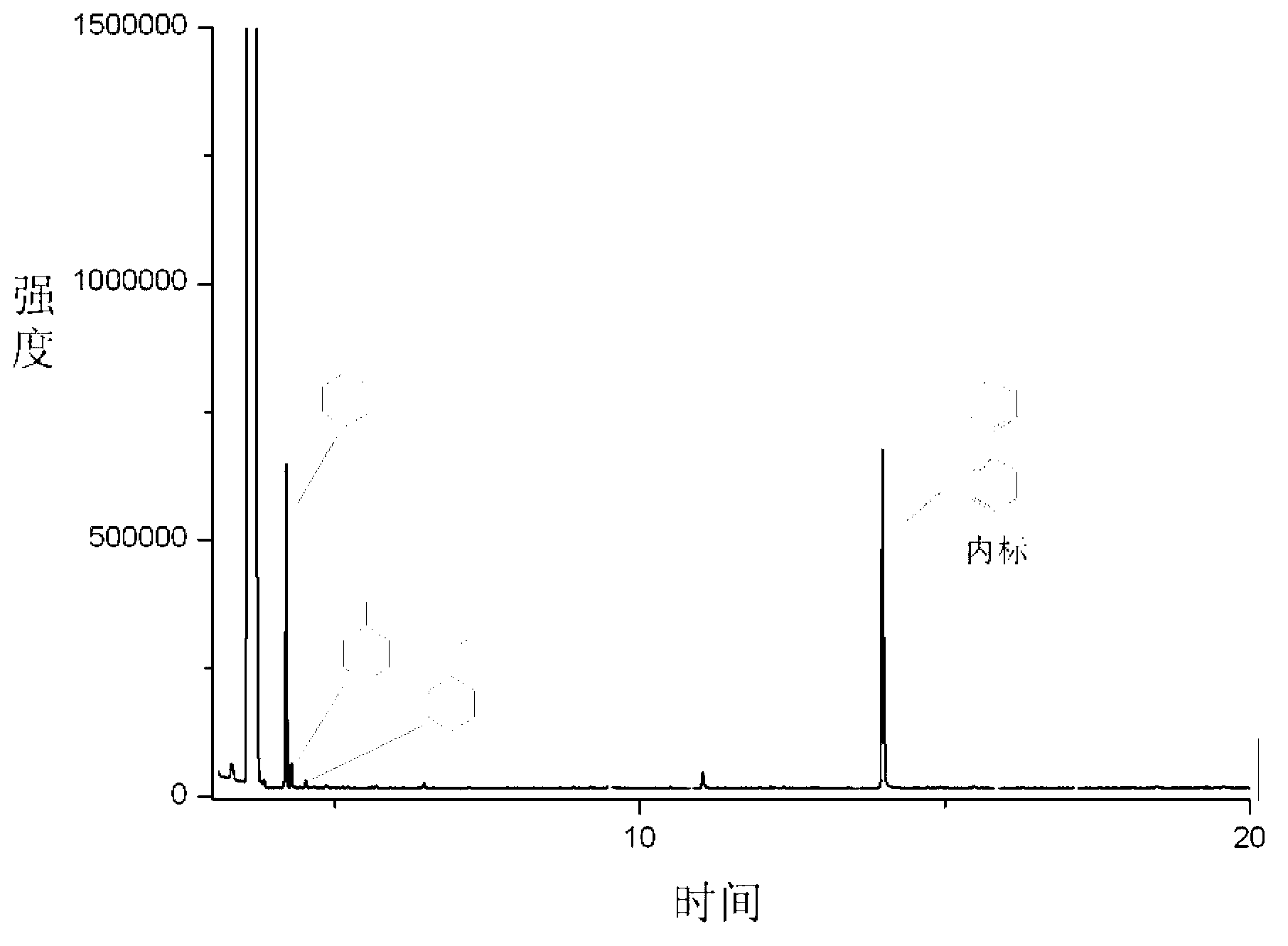

Image

Examples

Embodiment 1

[0029] Weigh 1 part of ethanol, 1 part of alkali lignin and 1 part of 30% volume hydrogen peroxide solution in a hydrothermal kettle, and keep at 40°C for 12 hours. After the reaction, the reaction solution was centrifuged to collect the liquid. The obtained liquid was added to the autoclave, and at the same time, 0.5 parts of Cu-Ru / SBA-ZrO 2 Catalyst, through 1MPa H 2 , 200°C for 24h. Finally, 12 wt% alkane product was obtained.

Embodiment 2

[0031] Weigh 10 parts of methanol, 1 part of sodium lignosulfonate and 5 parts of 30% volume hydrogen peroxide solution in a hydrothermal kettle, and keep at 40°C for 8 hours. After the reaction, the reaction solution was centrifuged to collect the liquid. The resulting liquid was added to the autoclave with 0.2 parts of Ru / SBA-ZrO 2 Catalyst, through 4MPaH 2 , 260 ° C reaction 8h. Finally, 9 wt% alkane product was obtained.

Embodiment 3

[0033] Weigh 50 parts of ethanol, 1 part of pyrolytic lignin and 3 parts of 30% volume hydrogen peroxide solution in a hydrothermal kettle, and keep at 60°C for 20h. After the reaction, the reaction solution was centrifuged to collect the liquid. The resulting liquid was added to the autoclave with 0.5 parts of Ru / SBA-CeO 2 Catalyst, feed 2MPa H 2 , 180 ° C reaction 8h. Finally, 19 wt% alkane product was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com