Preparation method of metal-nonmetal-codoped nano-titanium dioxide photocatalyst

A technology of nano-titanium dioxide and photocatalyst, which is applied in the field of photocatalysis, can solve the problems of easy falling off, etc., and achieve the effect of firm combination, simple preparation process and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] a. Take the concentration of 3.5mL as 9.11mol / L TiCl 4 Add 1g of modified polyacrylonitrile fiber dropwise to magnetically stirred 500mL distilled water, mix well, add 1g of modified polyacrylonitrile fiber, stir at room temperature for 1 hour, then heat to 55°C, keep for 7 hours, cool to room temperature, filter, and wash with distilled water until neutral. After drying to constant weight, a non-metallic nitrogen-doped modified nanometer titanium dioxide is obtained.

[0029] b. Take 0.05g of the nitrogen-doped modified nano-titanium dioxide prepared in step a and put it into 30mL 0.0050mol / L silver nitrate solution with pH=3.0, soak at room temperature for 50min, filter, wash with distilled water to neutrality, and dry To constant weight, namely Ag + , N co-doped modified nanometer titanium dioxide.

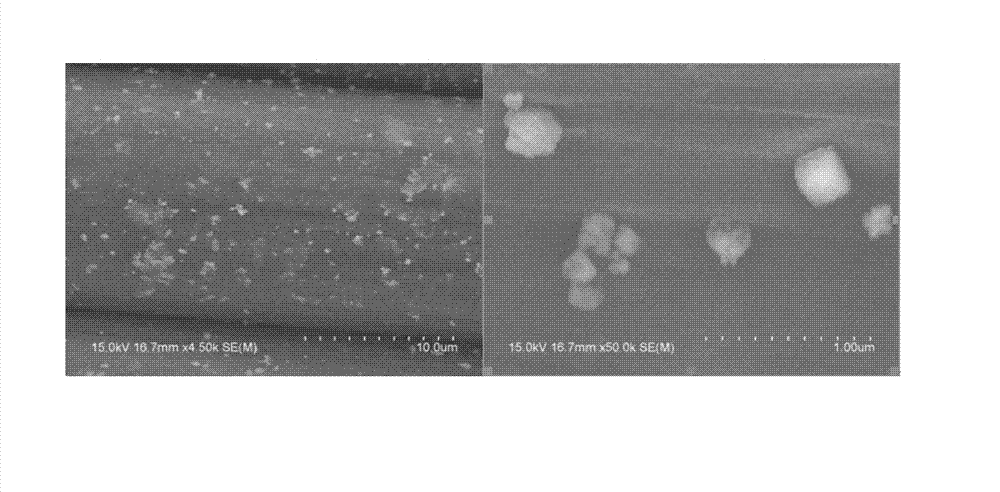

[0030] Its appearance is like figure 1 Shown.

Embodiment 2

[0032] The steps to divide b are:

[0033] Take 0.05g of the nitrogen-doped modified nano-titanium dioxide prepared in step a and put it in 30mL, 0.0050mol / L ferric chloride solution with pH=1.5, soak for 20min at room temperature, filter, wash with distilled water to neutrality, and dry To constant weight, Fe 3+ , N co-doped modified nanometer titanium dioxide.

[0034] The rest is the same as in Example 1.

Embodiment 3

[0036] The steps to divide b are:

[0037] Take 0.05g of the nitrogen-doped modified nano-titanium dioxide prepared in step a and put it into 30mL, 0.0015mol / L copper chloride solution with pH=5.0, soak for 20min at room temperature, filter, wash with distilled water to neutrality, and dry to constant Heavy, that is Cu 2+ , N co-doped modified nanometer titanium dioxide.

[0038] The rest is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com