Preparation method of carbon nano-tube vertical array structure with heterojunction

A carbon nanotube and array structure technology is applied in the field of controllable preparation of a vertical array structure of heterostructured carbon nanotubes, and achieves the effects of uniform structure change, precise structure and obvious structure change.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

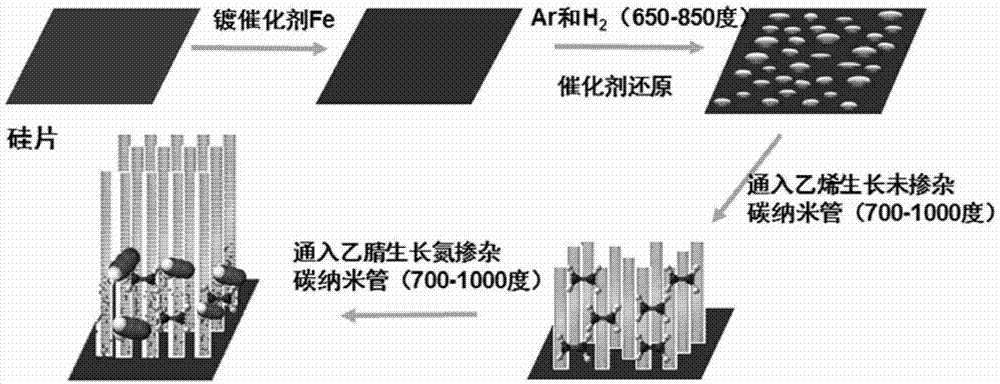

[0024] The invention provides a preparation method with a heterojunction (nitrogen-doped / undoped) carbon nanotube vertical array structure, which is prepared by a chemical vapor deposition method, comprising the following steps:

[0025] (1) Cleaning of the growth substrate: First, the Si substrate or SiO X / Si substrate (the surface of the Si substrate is covered with a layer of amorphous SiO X ) were ultrasonically cleaned in ethanol, acetone, and ethanol for 10 minutes, then rinsed with ethanol, and washed with high-purity N 2 Air dry the substrate surface.

[0026] (2) Preparation of catalyst film by ion sputtering: ionized Ar ions are used to bombard the surface of the target to deposit a film on the substrate, and the substrate is at room temperature during the coating process. The coating speed is adjustable, and the film thickness is measured by the device's quartz sensor.

[0027] (3) The chemical vapor deposition furnace is heated to the catalyst pretreatment temp...

Embodiment 1

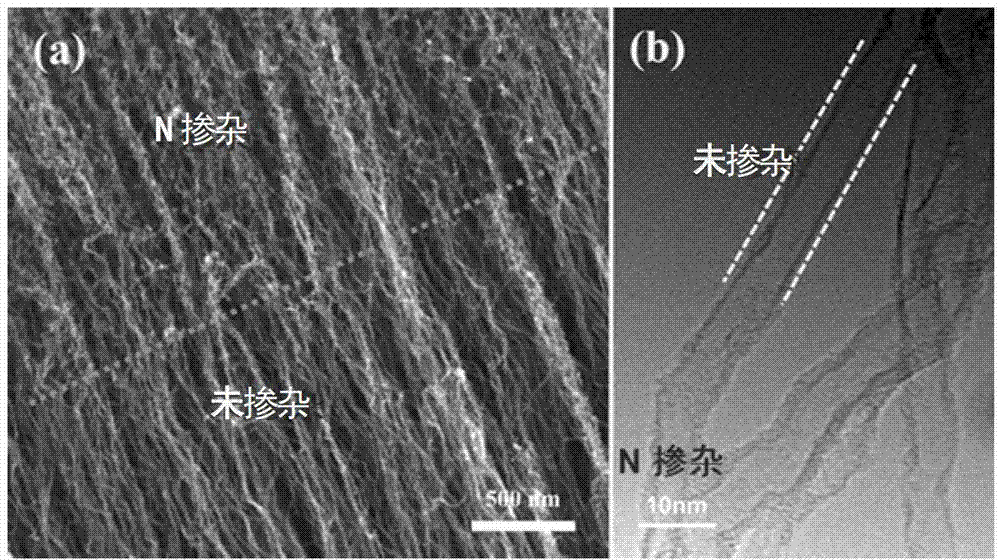

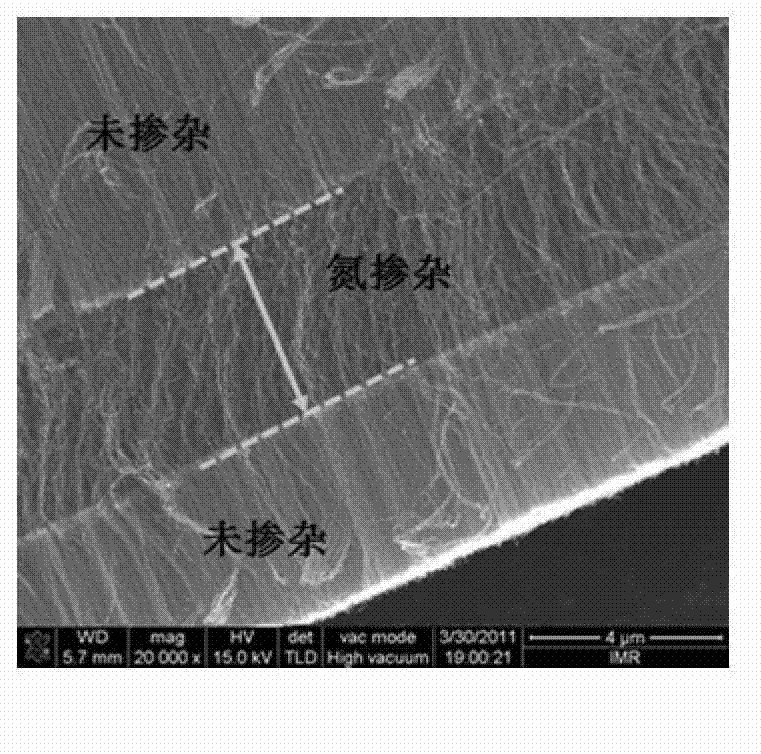

[0030] like figure 1 As shown, the experimental steps for preparing the vertical array structure of heterojunction carbon nanotubes are as follows: using the ion beam assisted deposition method on the cleaned SiO 2 / Si substrate deposit a layer of 20nm thick A1 2 O 3 barrier layer, and then deposit a 2 nm thick Fe film to prepare Fe catalyst nanoparticles. Fe catalyst thin film in Ar / H 2 Under the atmosphere, heat treatment at 750 °C for 10 min to reduce, and agglomerate to form nanoparticles for subsequent carbon nanotube growth. Access C of 80sccm 2 H 4 As a carbon source to grow a vertical array of carbon nanotubes, after growing at 900 °C for 5 minutes, open the Ar gas valve carrying acetonitrile, and use 10 ml / min of argon to carry acetonitrile at a temperature of 30 °C into the reaction zone, nitrogen-doped carbon The nanotube array begins to grow, and a heterojunction forms at the interface of the two carbon nanotubes. After 5 min growth at 900 °C, switch off H ...

Embodiment 2

[0032] Cleaned SiO using ion beam assisted deposition 2 / Si substrate deposited a layer of 20nm thick Al 2 O 3 barrier layer, and then deposit a 3 nm thick Fe film to prepare Fe catalyst nanoparticles. Fe catalyst thin film in Ar / H 2 Under the atmosphere, heat treatment at 700 °C for reduction for 15 min, and agglomerate to form nanoparticles for subsequent carbon nanotube growth. Quickly push the catalyst back to the low temperature zone, raise the temperature of the reactor to 850°C, push the catalyst to the reaction zone, and feed 50sccm of C 2 H 4 Vertical arrays of carbon nanotubes were grown as carbon sources; after 10 minutes of growth, the C 2 H 4 The flow rate of acetonitrile was reduced to 0 sccm, the Ar gas valve carrying acetonitrile was opened, and 30 ml / min of argon was used to carry acetonitrile with a temperature of 50 °C into the reaction zone, and the nitrogen-doped carbon nanotube arrays began to grow, and the heterojunction was formed between two carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com