Preparation method of piece-shaped tungsten disulfide nanometer lubricating oil additive

A lubricating oil additive, tungsten disulfide technology, applied in the direction of additives, chemical instruments and methods, nanotechnology, etc., can solve the problems of many defects in material morphology, low purity of nanosheets, affecting friction performance, etc., to achieve low cost, The effect of short reaction time and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Weigh tungsten powder (purity 99%) and sulfur powder (purity 99.9%) according to the molar ratio of 1:3, mix them into a stainless steel ball mill tank, use stainless steel balls as the ball milling medium, the ball material ratio is 10:1, and mill at 200rmp 4h. Then transfer it to a stainless steel reactor; place the reactor in a high-temperature box furnace, raise the temperature in the furnace to 750°C at a heating rate of 10°C / min, and keep it warm for 1h; naturally cool the temperature in the high-temperature box furnace to At room temperature (about 5 hours), the obtained dark brown powder is the flaky tungsten disulfide nano lubricating oil additive.

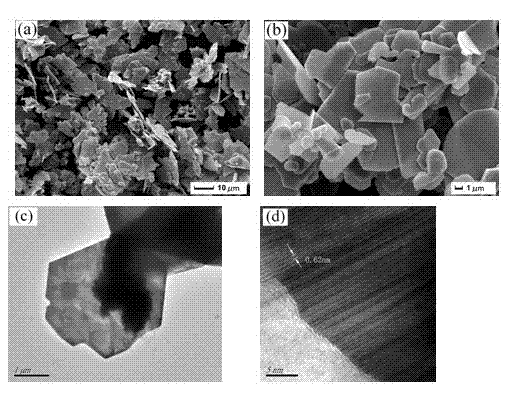

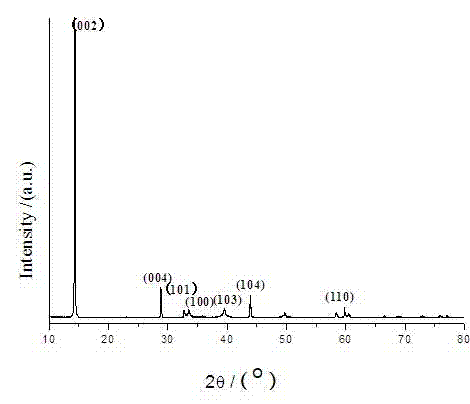

[0014] figure 1 It is the XRD pattern of flaky tungsten disulfide nano lubricating oil additive synthesized by solid phase method. from figure 1 It can be seen that all the XRD peak positions in the figure are consistent with the standard diffraction pattern (JCPDS84-1398), and there are no other miscellaneous p...

Embodiment 2

[0017] Weigh tungsten powder (purity 99%) and sulfur powder (purity 99.9%) according to the molar ratio of 1:2.5, mix them into a stainless steel ball mill tank, use stainless steel balls as the ball milling medium, the ball-to-material ratio is 10:1, and mill at 200rmp 4h. Then transfer to a stainless steel reaction kettle; place the reaction kettle in a high-temperature box furnace, raise the temperature in the furnace to 650°C at a heating rate of 10°C / min, and keep it warm for 1h; naturally cool the temperature in the high-temperature box furnace to At room temperature (about 5 hours), the obtained dark brown powder is the flaky tungsten disulfide nano lubricating oil additive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com