Preparation method of nanocrystalline Cu2O films

A nanocrystalline and thin film technology, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve problems such as low photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

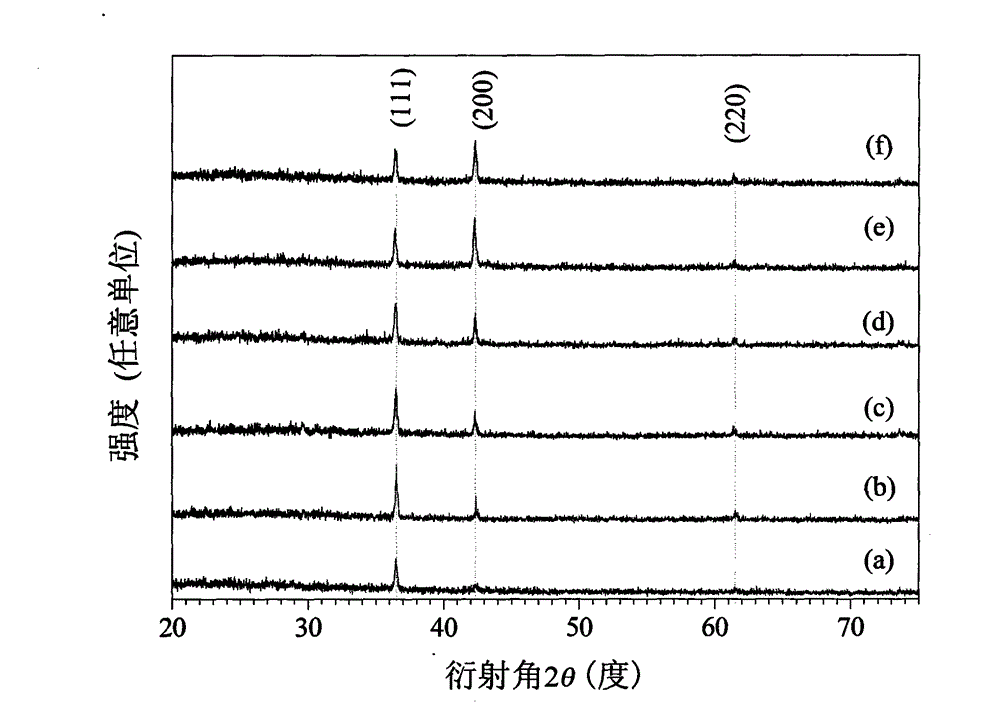

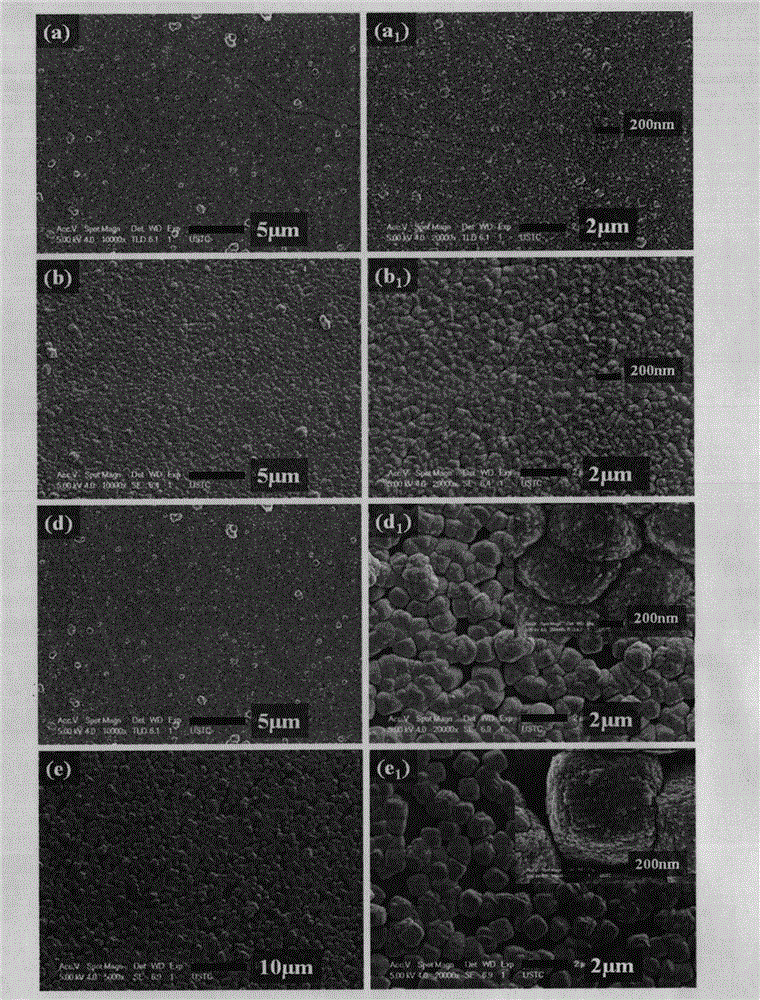

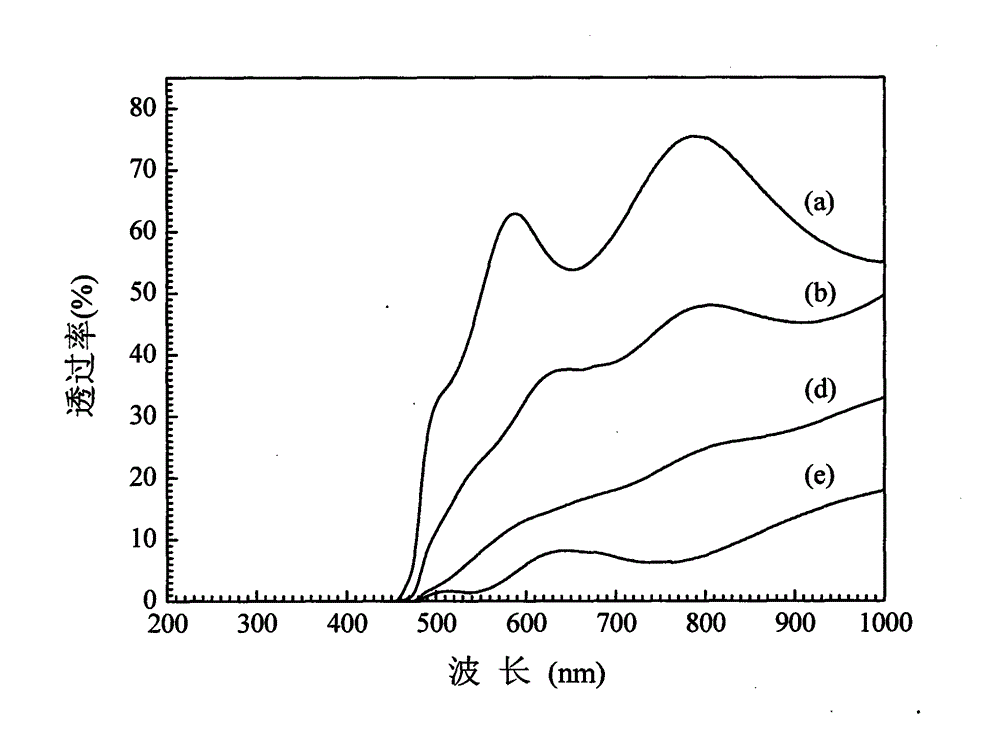

[0020] 1. According to the concentration ratio of 12:8:6, add the prepared sodium ascorbate and trisodium citrate solution in sequence to the 0.8mol / L copper sulfate solution, stir evenly, and put it into the pre-cleaned and activated lining after the complexation is sufficient. Make the volume of the solution 50ml, adjust the pH value of the solution to 8.8, react in a water bath at 80°C for 2 hours, take it out and clean it to get Cu 2 O film (a).

[0021] 2. According to the concentration ratio of 12:12:6, add the prepared sodium ascorbate and trisodium citrate solution in turn into the 0.8mol / L copper sulfate solution, stir evenly, and put it into the pre-cleaned and activated substrate after the complexation is sufficient. Make the volume of the solution 50ml, adjust the pH value of the solution to 8.8, react in a water bath at 80°C for 2 hours, take it out and clean it to get Cu 2 O film (b).

[0022] 3. According to the concentration ratio of 12:16:6, add the prepared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com