Tubular mesoporous manganese dioxide supercapacitor and preparation method thereof

A technology of supercapacitors and manganese dioxide, which is applied in the manufacture of hybrid/electric double layer capacitors, etc., can solve the problems of unfavorable specific capacity and high cost of active materials, and achieve the effects of low cost, good capacitance characteristics, and good environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

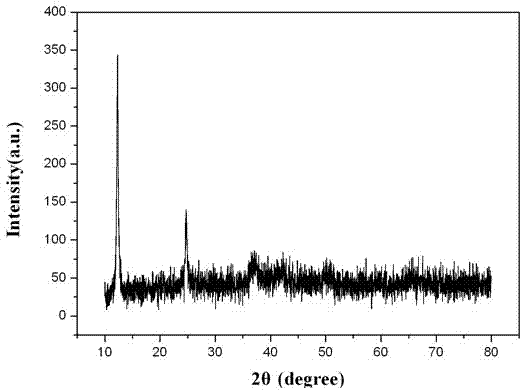

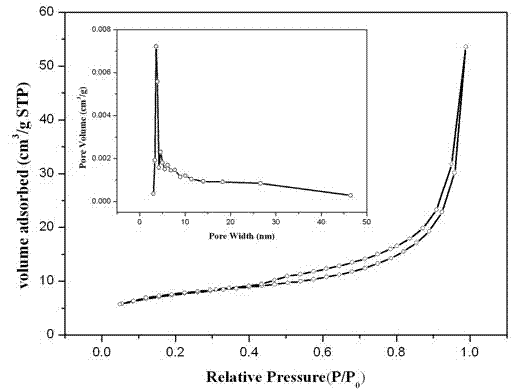

[0043] Dissolve 2 grams of potassium permanganate in 30 milliliters of deionized water, and then immerse 1.15 grams of cotton in the solution. After the cotton is completely soaked, take it out and dry it in an oven at 60°C. Then the cotton adsorbed with potassium permanganate was calcined in air at 500°C for 3 hours. Finally, the mesoporous manganese dioxide powder is obtained by washing the calcined product with water. figure 1 It is the XRD pattern of the final product, it can be seen from the figure that the product is δ-MnO 2 (The card number is No.80-1098). From the scanning electron microscope photos of the product, it can be seen that the morphology of the manganese dioxide powder is tubular (diameter 5 μm, average aspect ratio 18, inner diameter ratio 0.95). figure 2 is the nitrogen adsorption-desorption curve of the product. From the curve, it can be seen that the product is a mesoporous porous substance with an average pore diameter of about 5nm ( figure 2 ins...

Embodiment 2

[0046] Dissolve 1 gram of potassium permanganate in 30 milliliters of deionized water, and then soak 0.5 grams of cotton in the above solution. After the cotton is completely soaked, take it out and dry it in an oven at 60°C. Then the cotton adsorbed with potassium permanganate was calcined in air at 800°C for 3 hours. Finally, the tubular mesoporous manganese dioxide powder (diameter 4.5 μm, average aspect ratio 20, inner diameter ratio 0.96) was obtained by washing the calcined product with water. XRD test shows that the obtained product is also α-MnO 2 (The diffraction pattern is shown in Figure 5 ) (card number 44-0141). The nitrogen adsorption-desorption curve of the product also shows that the product is a mesoporous substance (average pore size is about 8nm). Its specific surface area is 40.12m 2 / g.

[0047] The obtained tubular mesoporous manganese dioxide powder was prepared into an electrode, which was prepared in 0.5M Na 2 SO 4 Among them, the potential ra...

Embodiment 3

[0049] Dissolve 3 grams of potassium permanganate in 30 milliliters of deionized water, and then soak 2.2 grams of cotton in the above solution. After the cotton is completely soaked, take it out and dry it in an oven at 60°C. Then the cotton adsorbed with potassium permanganate was calcined in the air at 700°C for 3 hours. Finally, the tubular mesoporous manganese dioxide powder was obtained by washing the calcined product with water (with a diameter of 6 μm, an average aspect ratio of 22, and a ratio of inner and outer diameters of 0.94). XRD test shows that the obtained product is γ-MnO 2 . The nitrogen adsorption-desorption curve of the product also shows that the product is a mesoporous substance (average pore size is about 4.1nm). Its specific surface area is 38.51m 2 / g.

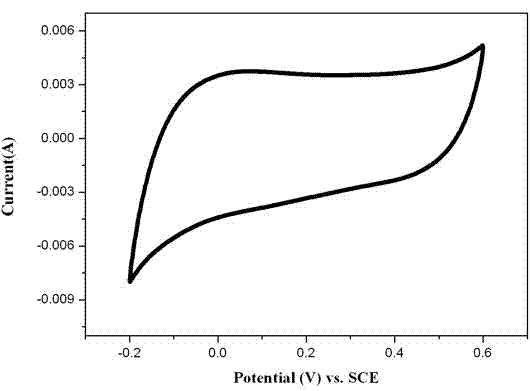

[0050] The obtained tubular mesoporous manganese dioxide powder was prepared into an electrode, which was prepared in 0.5M Na 2 SO 4 Among them, the potential range of -0.2-0.6 volts exhibits g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com